Blog

The Antibody Developability Crisis: Why 40% of Candidates Fail

Dec 15, 2025

You've identified a high-affinity antibody. It binds your target with nanomolar affinity. The selectivity looks perfect. In cell assays, it shows the exact mechanism you want. Then you try to formulate it at 100 mg/mL for subcutaneous injection, and it aggregates into an opaque gel within 24 hours.

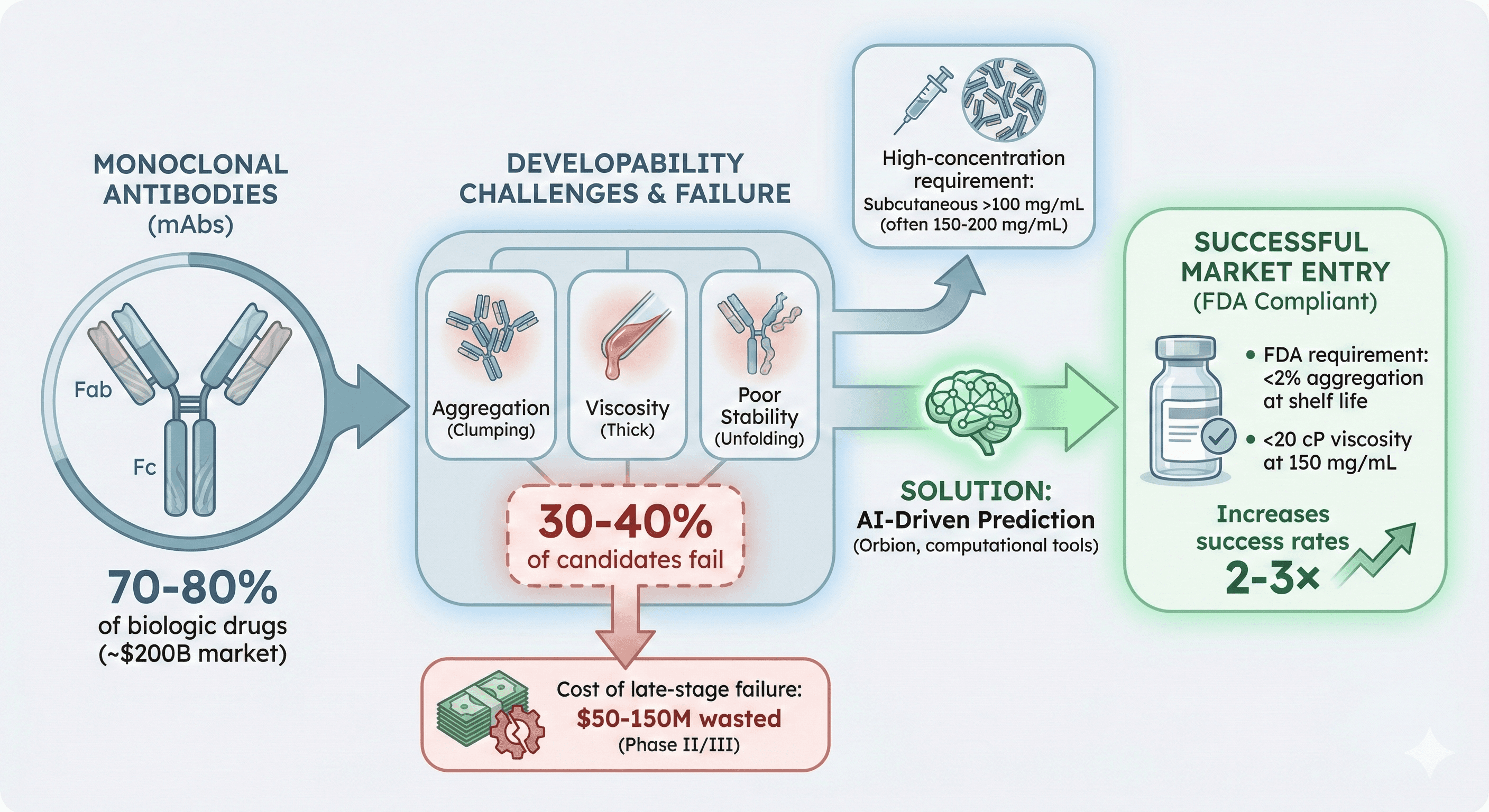

Welcome to the developability problem—the graveyard where 30-40% of antibody drug candidates die after millions of dollars in investment. Here's why it happens, and what makes an antibody "developable."

Key Takeaways

70-80% of biologic drugs are monoclonal antibodies (~$200B market)

30-40% of antibody candidates fail due to developability issues (aggregation, viscosity, poor stability)

Cost of late-stage failure: $50-150M wasted if developability issues found in Phase II/III

High-concentration requirement: Subcutaneous formulations need >100 mg/mL (often 150-200 mg/mL)

Industry standard: <2% aggregation at shelf life, <20 cP viscosity at 150 mg/mL

The problem: Traditional discovery optimizes for affinity only; developability is an afterthought

The Developability Crisis in Numbers

Market Size vs Failure Rate

The antibody market:

Monoclonal antibodies: $200B+ global market

Top-selling drugs: Humira ($21B/year), Keytruda ($17B/year), Opdivo ($7B/year)

Pipeline: 1,000+ antibodies in clinical trials

70-80% of approved biologics are antibodies

The failure rate:

30-40% of antibody candidates fail due to developability issues

These failures happen late (Phase II/III or even during manufacturing scale-up)

Average cost per failure: $50-150M

Time lost: 3-5 years

What kills antibodies:

Aggregation (40% of failures): Forms oligomers, loses activity, becomes immunogenic

High viscosity (25%): Cannot inject through small-gauge needle (patient compliance)

Poor stability (20%): Degrades during storage, short shelf life

Immunogenicity (10%): Anti-drug antibodies (ADAs) neutralize therapeutic

Low expression (5%): Cannot manufacture at commercial scale (>3 g/L in CHO)

The Economic Reality

Traditional development timeline:

Discovery: 1-2 years

Lead optimization: 1-2 years

IND-enabling studies: 1 year

Phase I: 1-2 years

Phase II: 2-3 years

Phase III: 2-4 years

Total: 8-14 years, $1-2B per approved drug

When developability failure is discovered:

Early (preclinical): Waste $10-30M, restart with new candidate

Phase I: Waste $40-80M

Phase II: Waste $100-200M

Phase III or manufacturing: Waste $300-500M, program may be terminated

The brutal math:

If you discover aggregation issues in Phase II: $150M gone

If viscosity problems appear during scale-up: $300M gone

Success rate drops from 60% → 20% if developability isn't addressed early

What Is Developability?

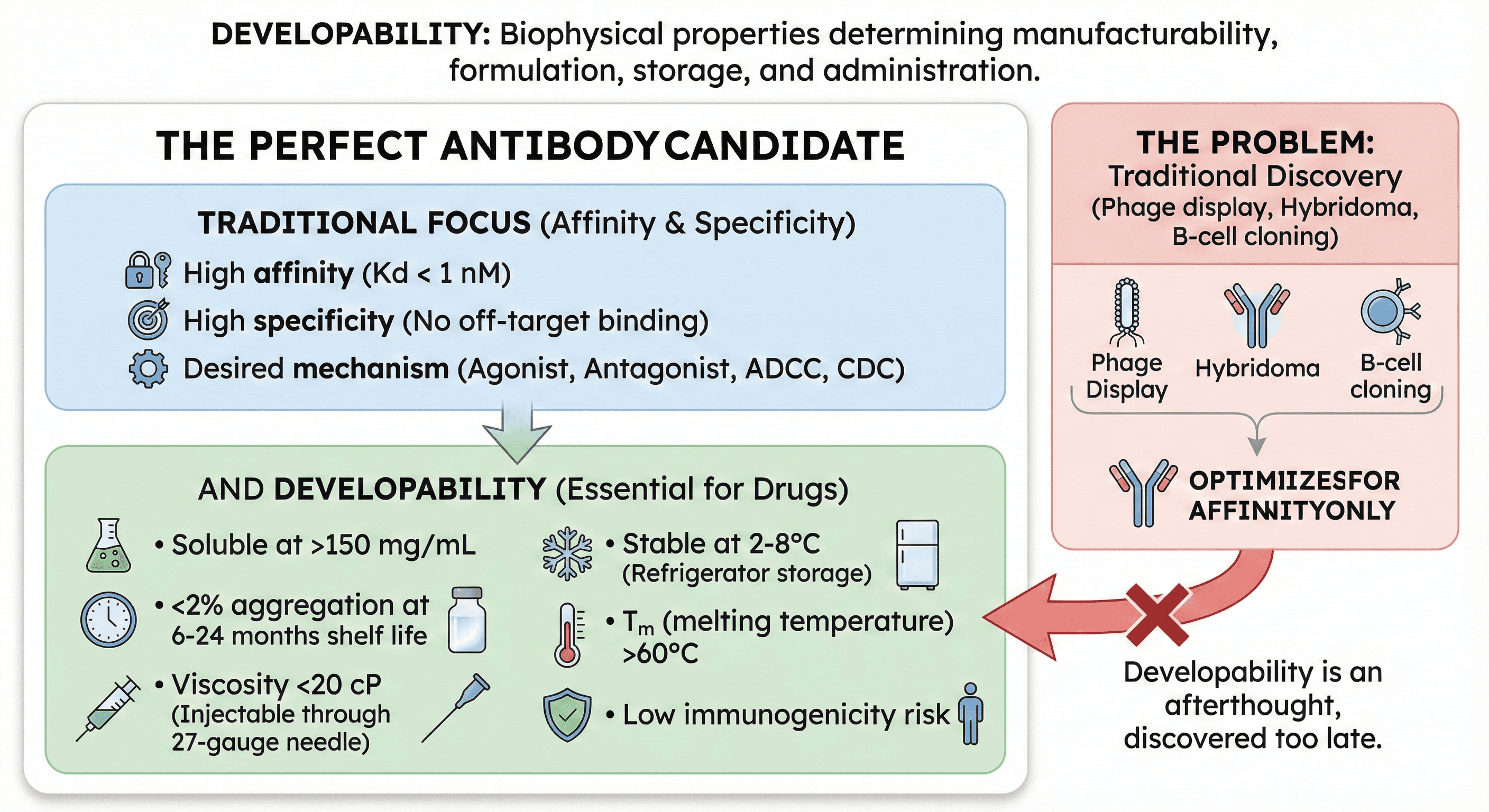

Developability is the set of biophysical properties that determine whether an antibody can be manufactured, formulated, stored, and administered as a drug.

The Perfect Antibody Candidate

Must have:

High affinity (Kd < 1 nM)

High specificity (no off-target binding)

Desired mechanism (agonist, antagonist, ADCC, CDC)

AND developability:

Soluble at >150 mg/mL (subcutaneous injection requires low volume)

<2% aggregation at 6-24 months shelf life (FDA requirement)

Viscosity <20 cP at 150 mg/mL (injectable through 27-gauge needle)

Stable at 2-8°C (refrigerator storage, patient-friendly)

Tm (melting temperature) >60°C for all domains (thermal stability)

Low immunogenicity risk (no anti-drug antibodies)

Expression titer >3 g/L in CHO cells (commercially viable manufacturing)

The Fundamental Problem

Traditional antibody discovery (phage display, hybridoma, B-cell cloning):

Optimizes for: Affinity

Screens for: Binding to target antigen

Selection pressure: Highest Kd wins

What's missing:

No selection for solubility

No screening for viscosity

No filtering for stability

No assessment of manufacturability

Result: You get high-affinity antibodies that often have terrible biophysical properties.

The Five Critical Quality Attributes (CQAs)

The FDA evaluates antibodies on these developability criteria. Fail any one, and your drug candidate is in jeopardy.

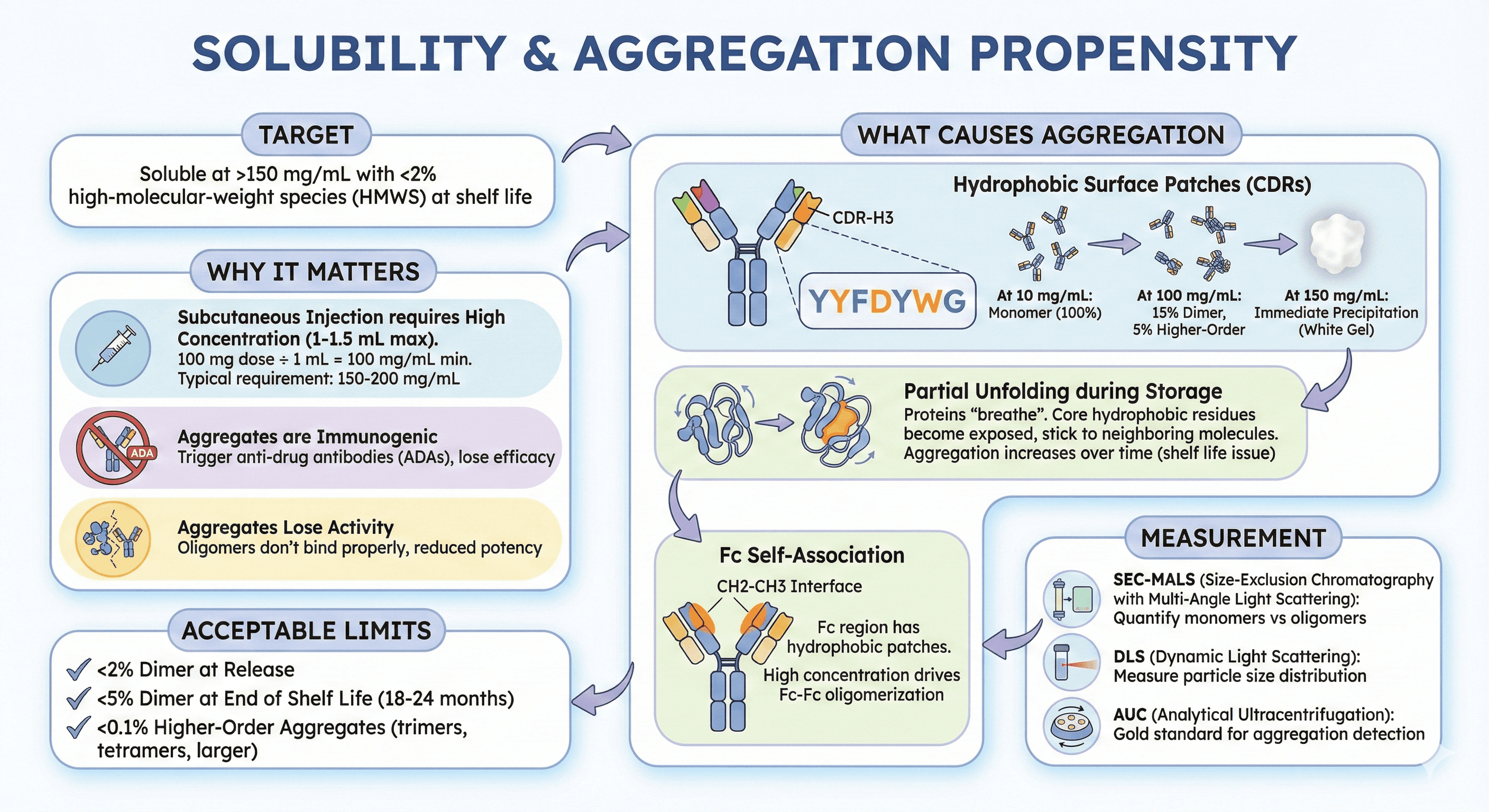

1. Solubility & Aggregation Propensity

Target: Soluble at >150 mg/mL with <2% high-molecular-weight species (HMWS) at shelf life

Why it matters:

Subcutaneous injection requires high concentration (1-1.5 mL max injection volume)

100 mg dose ÷ 1 mL volume = need 100 mg/mL minimum

Typical requirement: 150-200 mg/mL (includes overfill, stability margin)

Aggregates are immunogenic: Trigger anti-drug antibodies (ADAs), lose efficacy

Aggregates lose activity: Oligomers don't bind properly, reduced potency

What causes aggregation:

Hydrophobic surface patches:

Antibody CDRs (complementarity-determining regions) contain the binding site

To bind hydrophobic pockets on antigens, CDRs often have hydrophobic residues (Tyr, Phe, Trp, Leu, Ile)

These hydrophobic CDRs can stick to each other at high concentration

Result: Reversible self-association → irreversible aggregation

Example:

CDR-H3 with sequence YYFDYWG (3 Tyr, 1 Phe, 1 Trp)

At 10 mg/mL: Monomer (100%)

At 100 mg/mL: 15% dimer, 5% higher-order aggregates

At 150 mg/mL: Immediate precipitation (white gel)

Partial unfolding during storage:

Proteins "breathe" (transiently unfold and refold)

During unfolding, core hydrophobic residues become exposed

Exposed regions can stick to neighboring molecules

Result: Aggregation increases over time (shelf life issue)

Fc self-association:

The Fc (constant region) can also aggregate

CH2-CH3 interface has hydrophobic patches

At high concentration, Fc-Fc interactions drive oligomerization

Measurement:

SEC-MALS (size-exclusion chromatography with multi-angle light scattering): Quantify monomers vs oligomers

DLS (dynamic light scattering): Measure particle size distribution

AUC (analytical ultracentrifugation): Gold standard for aggregation detection

Acceptable limits:

<2% dimer at release

<5% dimer at end of shelf life (18-24 months)

<0.1% higher-order aggregates (trimers, tetramers, larger)

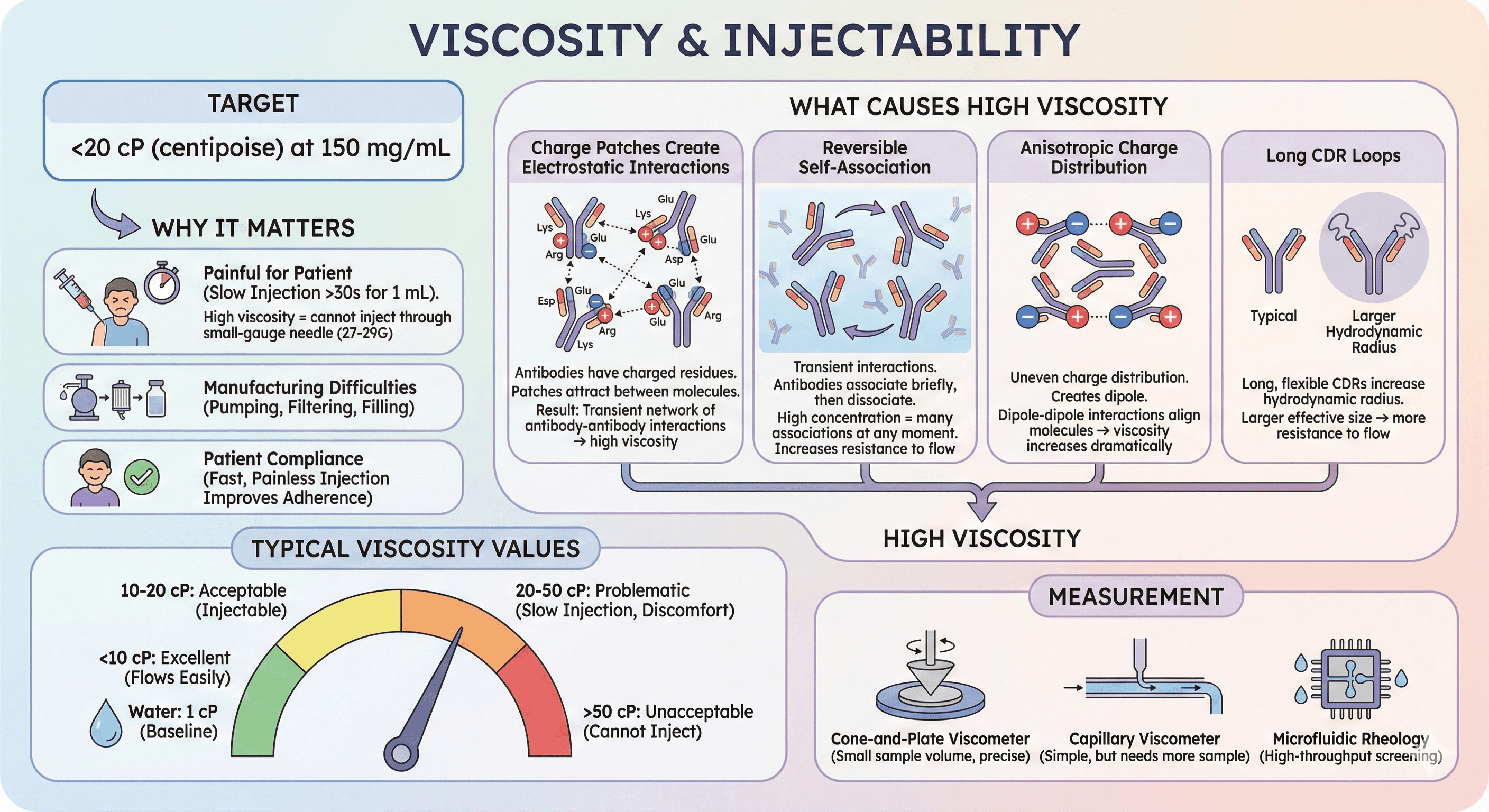

2. Viscosity

Target: <20 cP (centipoise) at 150 mg/mL

Why it matters:

High viscosity = cannot inject through small-gauge needle (27-29G)

Slow injection = painful for patient (>30 seconds for 1 mL)

Manufacturing: Difficult to pump, filter, fill into vials/syringes

Patient compliance: Fast, painless injection improves adherence to treatment

What causes high viscosity:

Charge patches create electrostatic interactions:

Antibodies have charged residues (Lys, Arg = positive; Glu, Asp = negative)

If positive charges cluster on one region (patch), negative charges cluster elsewhere

These patches attract between molecules at high concentration

Result: Transient network of antibody-antibody interactions → high viscosity

Reversible self-association:

Unlike aggregation (irreversible), viscosity involves transient interactions

Antibodies associate briefly, then dissociate

At high concentration, many molecules are associated at any given moment

This increases resistance to flow (viscosity)

Anisotropic charge distribution:

"Anisotropic" = uneven charge distribution

If one side of antibody is positive, other side negative → creates dipole

Dipole-dipole interactions align molecules → viscosity increases dramatically

Long CDR loops:

Long, flexible CDRs increase hydrodynamic radius

Larger effective size → more resistance to flow

Typical viscosity values:

Water: 1 cP (baseline)

<10 cP: Excellent (flows easily)

10-20 cP: Acceptable (injectable)

20-50 cP: Problematic (slow injection, patient discomfort)

50 cP: Unacceptable (cannot inject through standard needles)

Measurement:

Cone-and-plate viscometer (small sample volume, precise)

Capillary viscometer (simple, but needs more sample)

Microfluidic rheology (high-throughput screening)

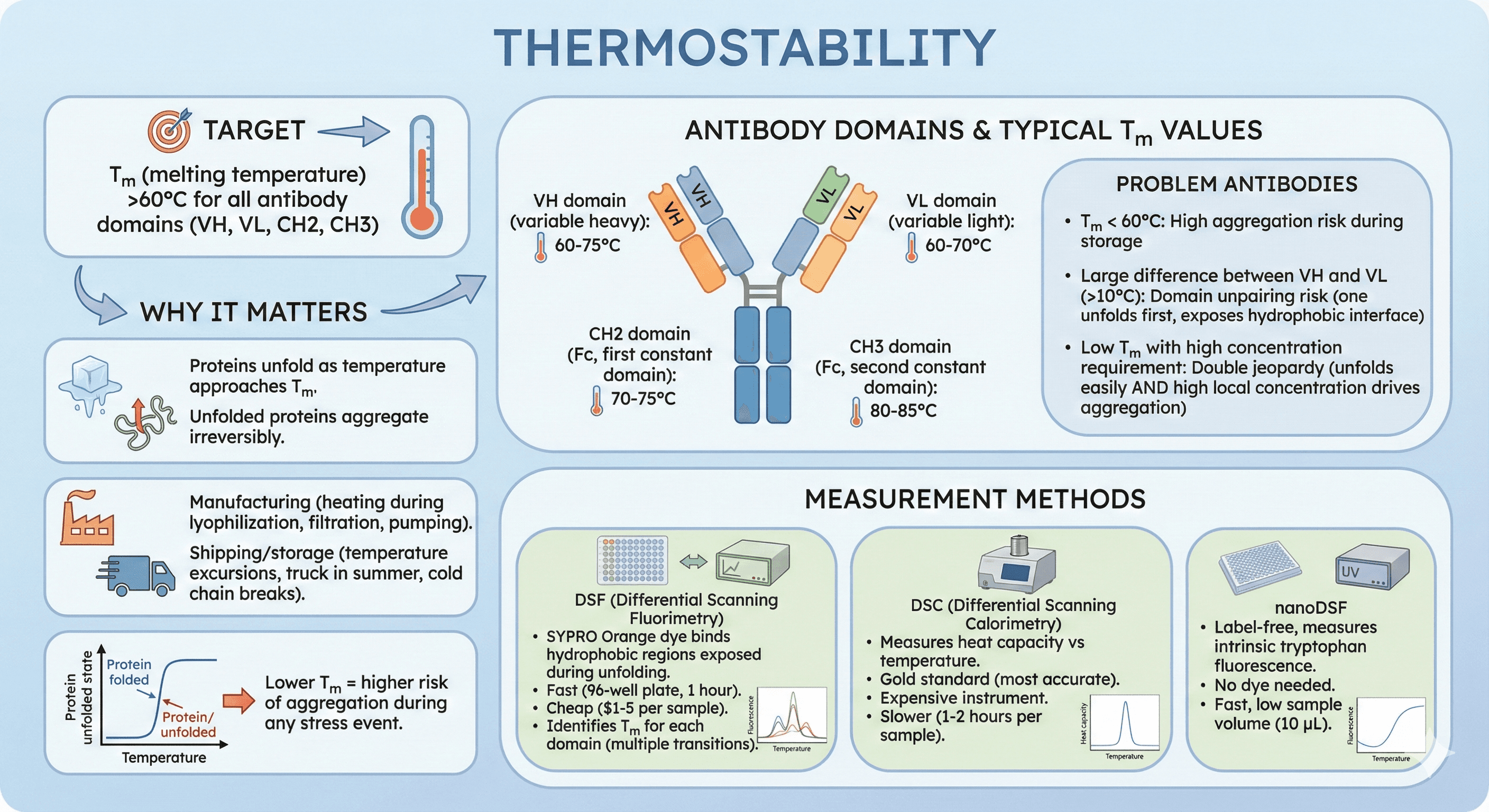

3. Thermal Stability (Tm)

Target: Tm (melting temperature) >60°C for all antibody domains (VH, VL, CH2, CH3)

Why it matters:

Proteins unfold as temperature approaches Tm

Unfolded proteins aggregate irreversibly

During manufacturing: Transient heating can occur (lyophilization, filtration, pumping)

Shipping/storage: Temperature excursions (truck in summer, cold chain breaks)

Lower Tm = higher risk of aggregation during any stress event

Antibody domains and their typical Tm values:

VH domain (variable heavy): 60-75°C

VL domain (variable light): 60-70°C

CH2 domain (Fc, first constant domain): 70-75°C

CH3 domain (Fc, second constant domain): 80-85°C

Problem antibodies:

Tm < 60°C: High aggregation risk during storage

Large difference between VH and VL (>10°C): Domain unpairing risk (one unfolds first, exposes hydrophobic interface)

Low Tm with high concentration requirement: Double jeopardy (unfolds easily AND high local concentration drives aggregation)

Measurement methods:

DSF (Differential Scanning Fluorimetry): SYPRO Orange dye binds hydrophobic regions exposed during unfolding

Fast (96-well plate, 1 hour)

Cheap ($1-5 per sample)

Identifies Tm for each domain (multiple transitions)

DSC (Differential Scanning Calorimetry): Measures heat capacity vs temperature

Gold standard (most accurate)

Expensive instrument

Slower (1-2 hours per sample)

nanoDSF: Label-free, measures intrinsic tryptophan fluorescence

No dye needed

Fast, low sample volume (10 μL)

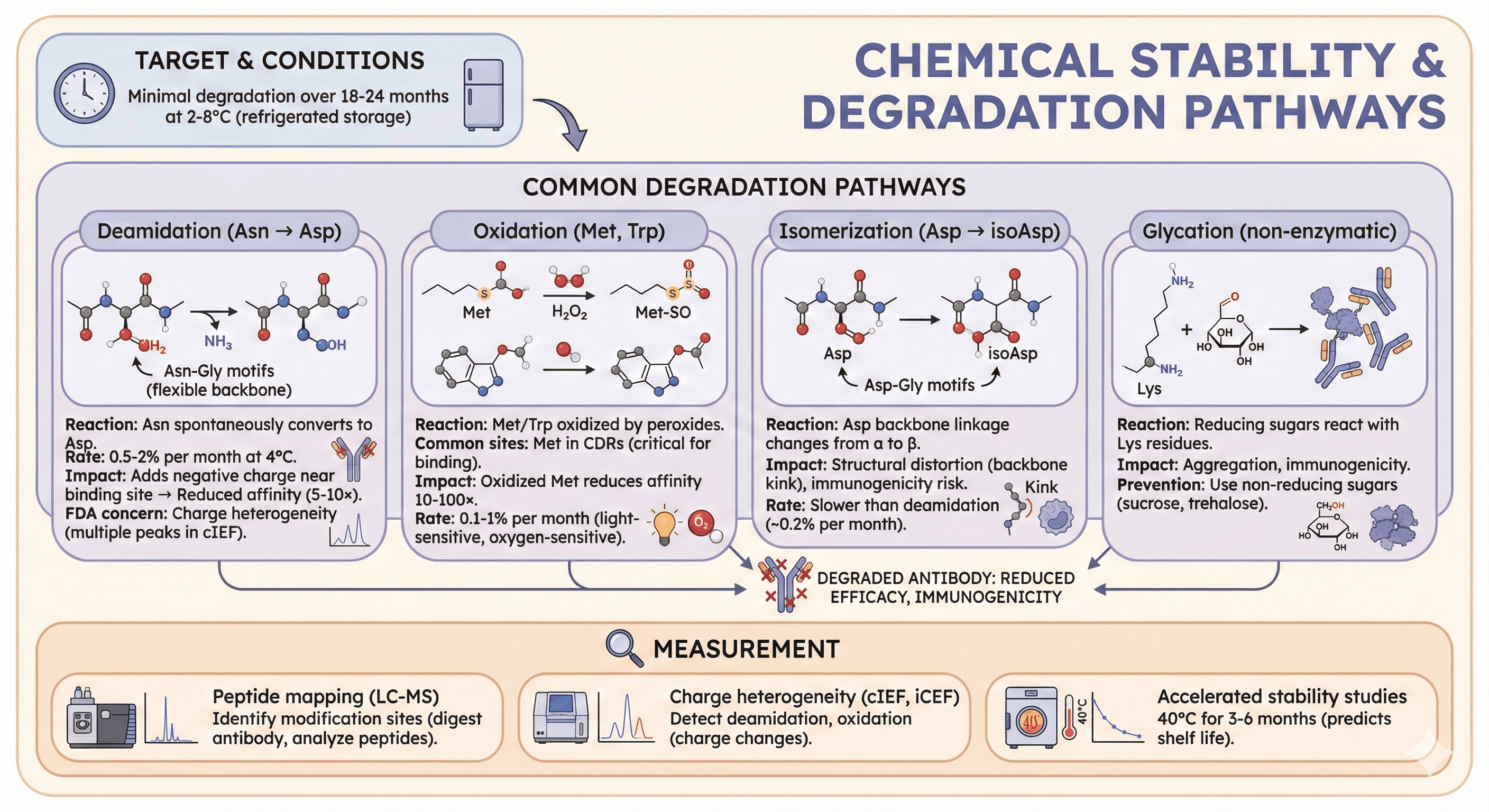

4. Chemical Stability

Target: Minimal degradation over 18-24 months at 2-8°C (refrigerated storage)

Common degradation pathways:

Deamidation (Asn → Asp):

Reaction: Asparagine (Asn) spontaneously converts to Aspartate (Asp)

Susceptible sequences: Asn-Gly motifs (Gly has no side chain, allows backbone flexibility)

Rate: 0.5-2% per month at 4°C (pH-dependent)

Impact: Adds negative charge near binding site → reduced affinity (5-10×)

FDA concern: Charge heterogeneity (multiple peaks in cIEF, charge-based separation)

Oxidation (Met, Trp):

Reaction: Methionine (Met) or Tryptophan (Trp) oxidized by peroxides (H₂O₂, lipid peroxides)

Common sites: Met in CDRs (critical for binding)

Impact: Oxidized Met reduces affinity 10-100× (sulfur becomes sulfoxide or sulfone)

Rate: 0.1-1% per month (light-sensitive, oxygen-sensitive)

Isomerization (Asp → isoAsp):

Reaction: Aspartate (Asp) backbone linkage changes from α to β (isoAsp)

Susceptible sequences: Asp-Gly motifs

Impact: Structural distortion (backbone kink), immunogenicity risk

Rate: Slower than deamidation (~0.2% per month)

Glycation (non-enzymatic):

Reaction: Reducing sugars (glucose, fructose) react with Lys residues

Impact: Aggregation, immunogenicity (glycated proteins recognized as foreign)

Prevention: Use non-reducing sugars (sucrose, trehalose in formulation)

Measurement:

Peptide mapping (LC-MS): Identify modification sites (digest antibody, analyze peptides)

Charge heterogeneity (cIEF, iCEF): Detect deamidation, oxidation (charge changes)

Accelerated stability studies: 40°C for 3-6 months (predicts shelf life)

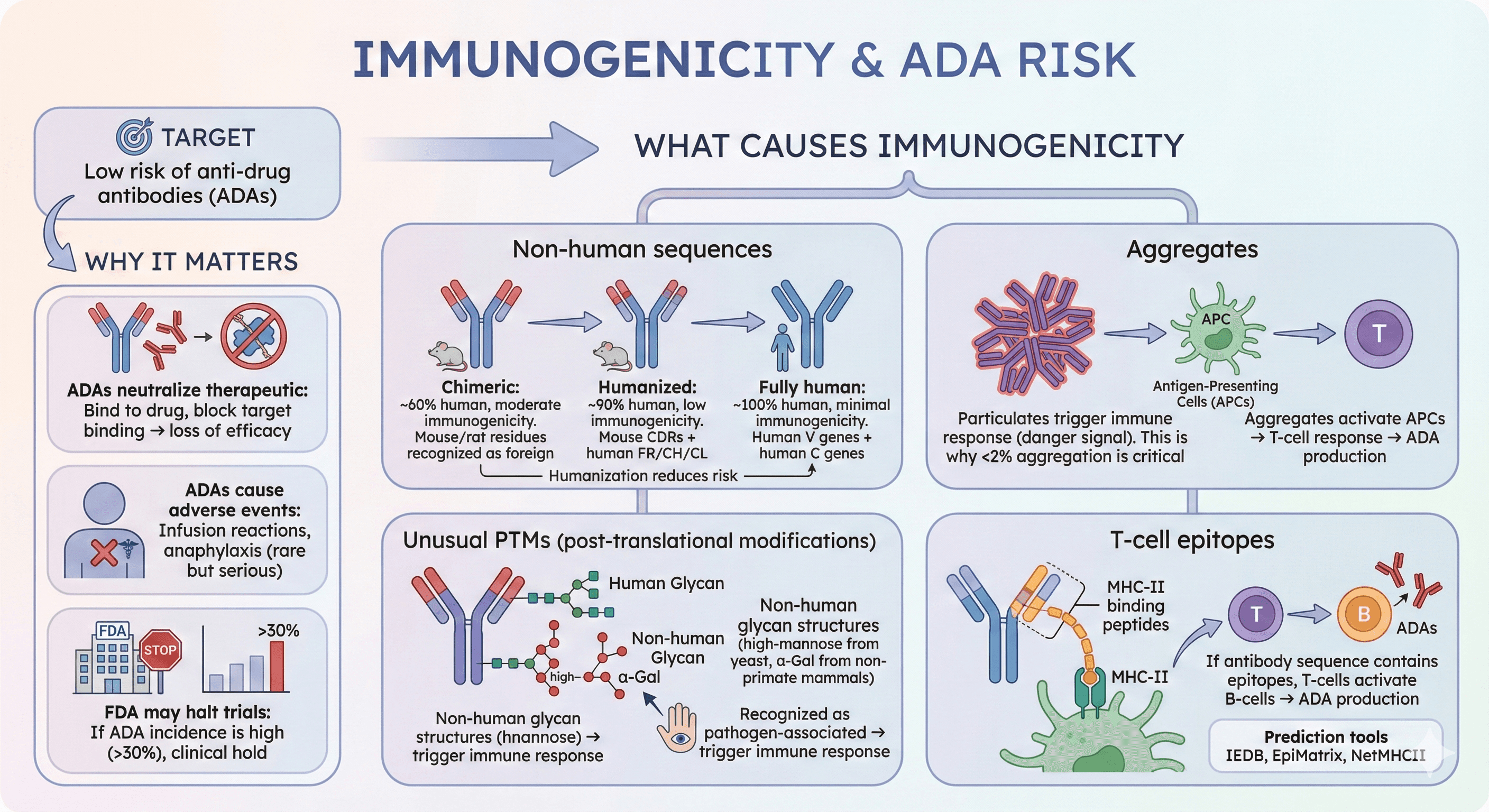

5. Immunogenicity Risk

Target: Low risk of anti-drug antibodies (ADAs)

Why it matters:

ADAs neutralize therapeutic: Bind to drug, block binding to target → loss of efficacy

ADAs cause adverse events: Infusion reactions, anaphylaxis (rare but serious)

FDA may halt trials: If ADA incidence is high (>30%), clinical hold

What causes immunogenicity:

Non-human sequences:

Mouse/rat residues in CDRs or frameworks: Immune system recognizes as foreign

Humanization reduces risk:

Chimeric antibodies (mouse VH/VL + human CH/CL): ~60% human, moderate immunogenicity

Humanized antibodies (mouse CDRs + human FR/CH/CL): ~90% human, low immunogenicity

Fully human antibodies (human V genes + human C genes): ~100% human, minimal immunogenicity

Aggregates:

Particulates trigger immune response (danger signal)

Aggregates activate antigen-presenting cells (APCs) → T-cell response → ADA production

This is why <2% aggregation is critical (FDA requirement)

Unusual PTMs (post-translational modifications):

Non-human glycan structures (high-mannose from yeast, α-Gal from non-primate mammals)

These glycans trigger immune response (recognized as pathogen-associated)

T-cell epitopes:

MHC-II binding peptides (9-15 amino acids)

If antibody sequence contains epitopes, T-cells activate B-cells → ADA production

Prediction tools: IEDB, EpiMatrix, NetMHCII

The Antibody Structure: Where Problems Hide

IgG Architecture Recap

A typical IgG1 antibody (~150 kDa):

2 Heavy chains (50 kDa each): VH-CH1-Hinge-CH2-CH3

2 Light chains (25 kDa each): VL-CL

12 intrachain disulfide bonds (within domains)

4 interchain disulfide bonds (linking chains)

1 N-glycosylation site per heavy chain (Asn297 in CH2 domain)

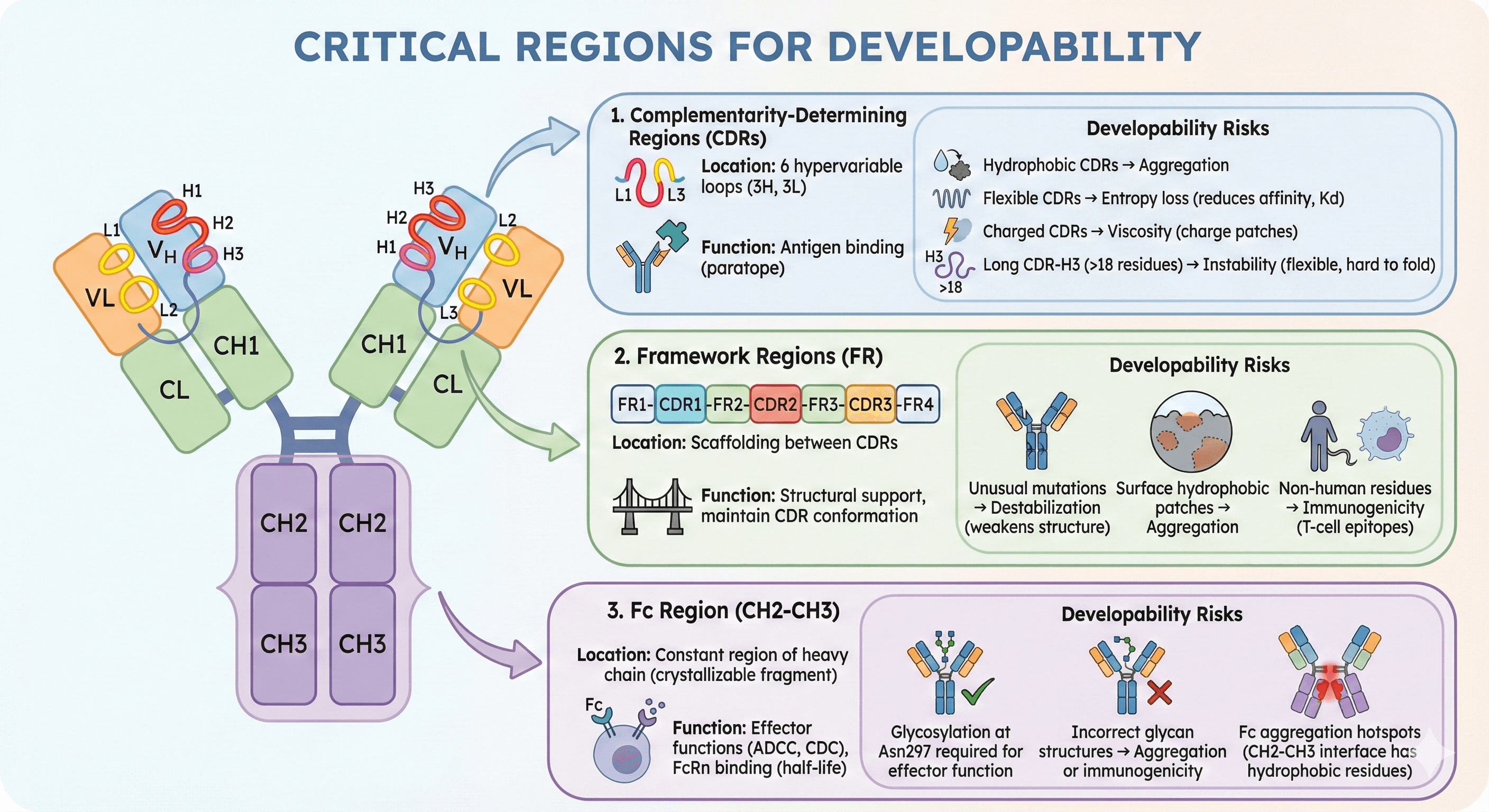

Critical Regions for Developability

1. Complementarity-Determining Regions (CDRs)

Location: 6 hypervariable loops (3 on heavy chain: H1, H2, H3; 3 on light chain: L1, L2, L3)

Function: Antigen binding (paratope)

Developability risks:

Hydrophobic CDRs → aggregation

Flexible CDRs → entropy loss (reduces binding affinity, Kd affected)

Charged CDRs → viscosity (charge patches)

Long CDR-H3 (>18 residues) → instability (flexible loop, hard to fold correctly)

2. Framework Regions (FR)

Location: Scaffolding between CDRs (FR1-CDR1-FR2-CDR2-FR3-CDR3-FR4)

Function: Structural support, maintain CDR conformation

Developability risks:

Unusual mutations → destabilization (non-consensus residues weaken structure)

Surface hydrophobic patches → aggregation

Non-human residues → immunogenicity (T-cell epitopes)

3. Fc Region (CH2-CH3)

Location: Constant region of heavy chain (crystallizable fragment)

Function: Effector functions (ADCC, CDC), FcRn binding (half-life)

Developability risks:

Glycosylation at Asn297 required for effector function (ADCC/CDC needs glycan)

Incorrect glycan structures → aggregation or immunogenicity

Fc aggregation hotspots (CH2-CH3 interface has hydrophobic residues)

Real-World Failure Modes

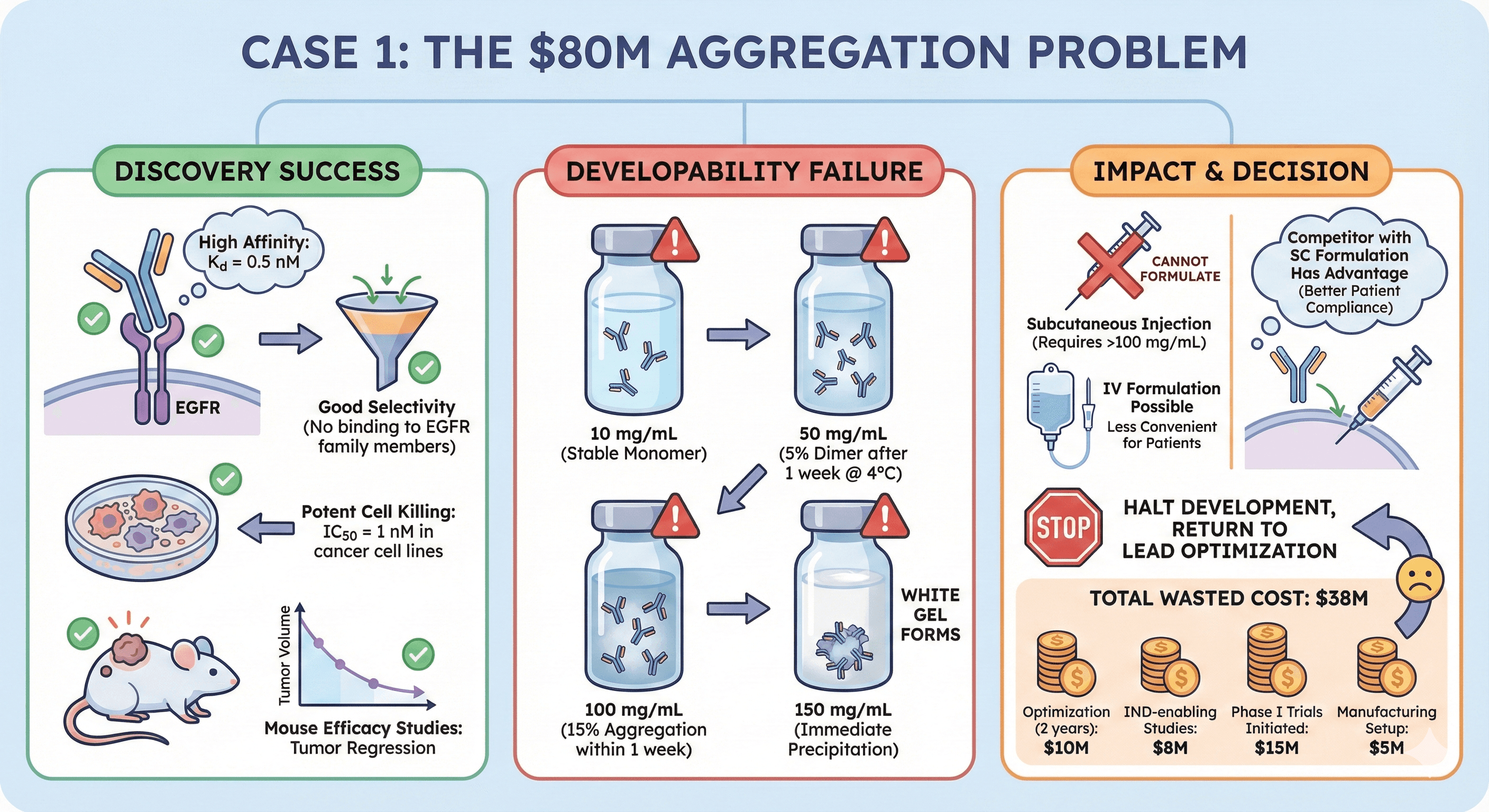

Case 1: The $80M Aggregation Problem

Candidate: Anti-EGFR antibody for solid tumors

Discovery success:

High affinity: Kd = 0.5 nM

Good selectivity (no binding to EGFR family members)

Potent cell killing: IC50 = 1 nM in cancer cell lines

Mouse efficacy studies: Tumor regression in xenograft models

Developability failure:

At 10 mg/mL: Stable (monomer)

At 50 mg/mL: 5% dimer after 1 week at 4°C

At 100 mg/mL: 15% aggregation within 1 week

At 150 mg/mL: Immediate precipitation (white gel forms)

Impact:

Cannot formulate for subcutaneous injection (requires >100 mg/mL)

IV formulation possible (lower concentration), but less convenient for patients

Competitor with SC formulation has advantage (better patient compliance)

Decision: Halt development, return to lead optimization

Cost:

2 years in lead optimization: $10M

IND-enabling studies: $8M

Phase I trials initiated: $15M

Manufacturing setup: $5M

Total wasted: $38M

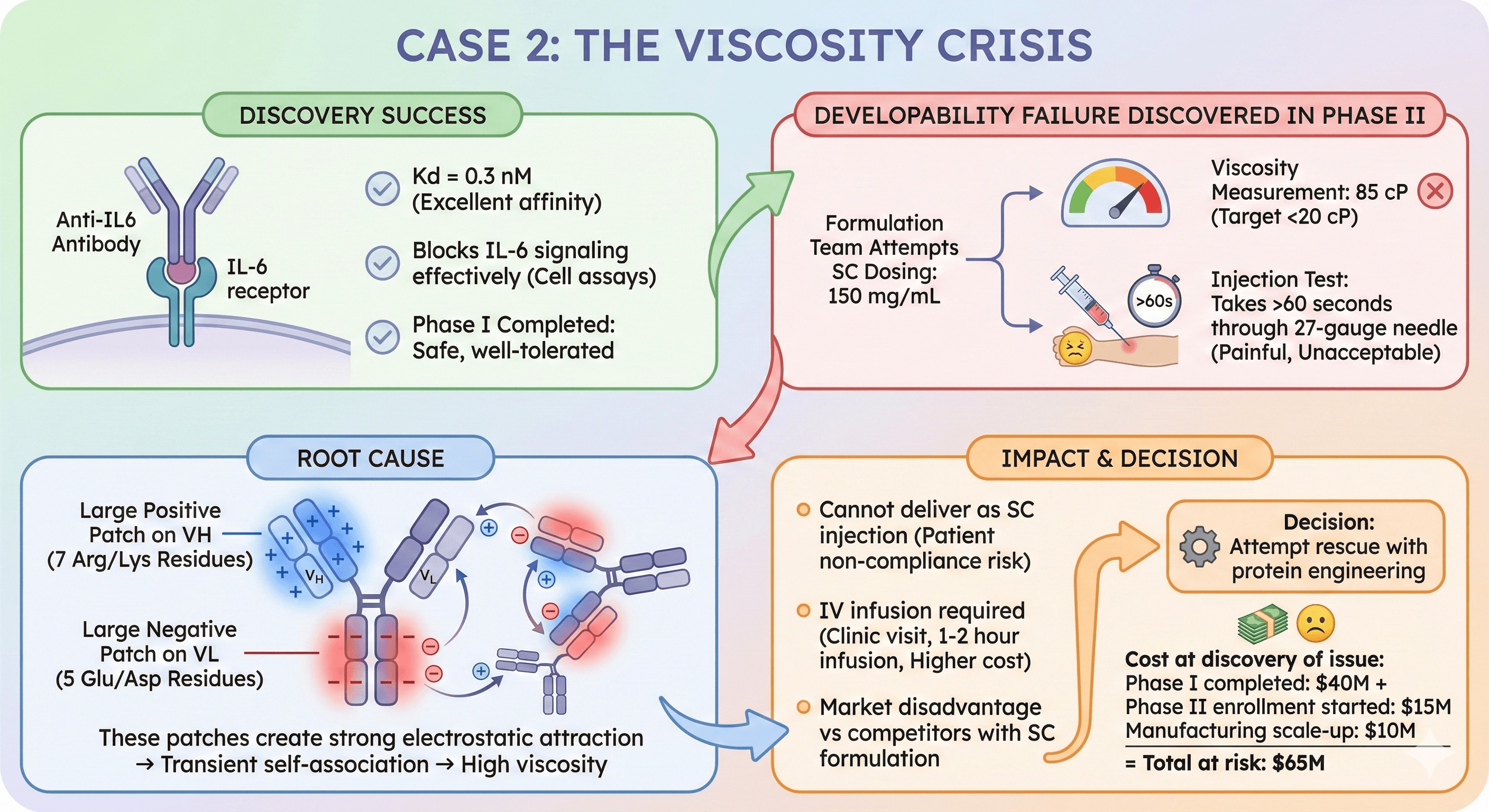

Case 2: The Viscosity Crisis

Candidate: Anti-IL6 antibody for rheumatoid arthritis

Discovery success:

Kd = 0.3 nM (excellent affinity)

Blocks IL-6 signaling effectively (cell assays)

Phase I completed: Safe, well-tolerated

Developability failure discovered in Phase II:

Formulation team attempts SC dosing: 150 mg/mL

Viscosity measurement: 85 cP (target <20 cP)

Injection test: Takes >60 seconds through 27-gauge needle (painful, unacceptable)

Root cause:

Charge patch analysis: Large positive patch on VH (7 Arg/Lys residues)

Large negative patch on VL (5 Glu/Asp residues)

These patches create strong electrostatic attraction → transient self-association → high viscosity

Impact:

Cannot deliver as SC injection (patient non-compliance risk)

IV infusion required (clinic visit, 1-2 hour infusion, higher cost)

Market disadvantage vs competitors with SC formulation

Decision: Attempt rescue with protein engineering

Cost at discovery of issue:

Phase I completed: $40M

Phase II enrollment started: $15M

Manufacturing scale-up: $10M

Total at risk: $65M

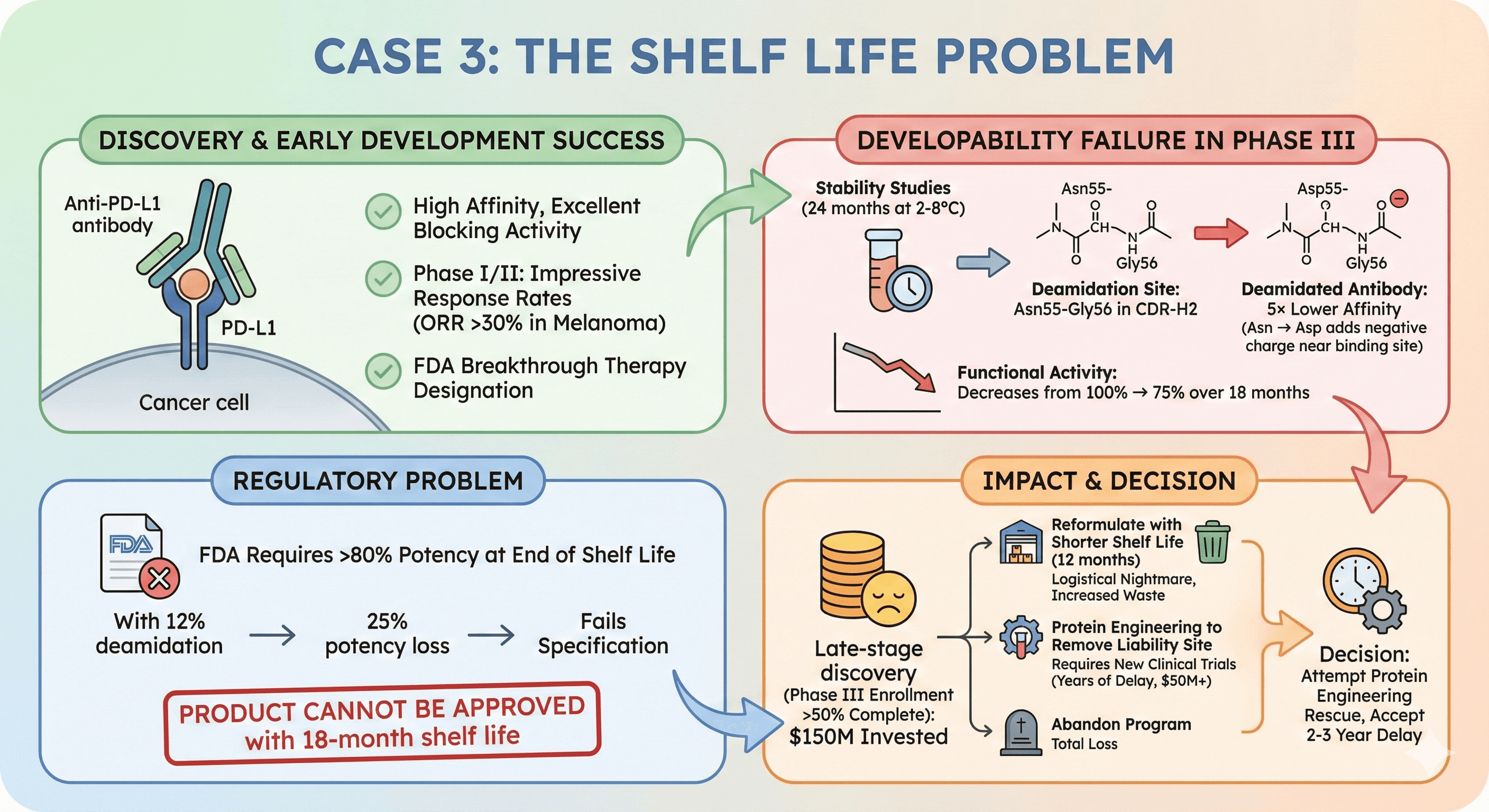

Case 3: The Shelf Life Problem

Candidate: Anti-PD-L1 antibody for cancer immunotherapy

Discovery & early development success:

High affinity, excellent blocking activity

Phase I/II: Impressive response rates (ORR >30% in melanoma)

FDA breakthrough therapy designation

Developability failure in Phase III:

Stability studies (24 months at 2-8°C): 12% deamidation

Deamidation site: Asn55-Gly56 in CDR-H2

Deamidated antibody: 5× lower affinity (Asn → Asp adds negative charge near binding site)

Functional activity: Decreases from 100% → 75% over 18 months

Regulatory problem:

FDA requires >80% potency at end of shelf life

With 12% deamidation → 25% potency loss → fails specification

Product cannot be approved with 18-month shelf life

Impact:

Late-stage discovery (Phase III enrollment >50% complete): $150M invested

Options:

Reformulate with shorter shelf life (12 months) → logistical nightmare, increased waste

Protein engineering to remove liability site → requires new clinical trials (years of delay, $50M+)

Abandon program → total loss

Decision: Attempt protein engineering rescue, accept 2-3 year delay

Why Traditional Discovery Fails at Developability

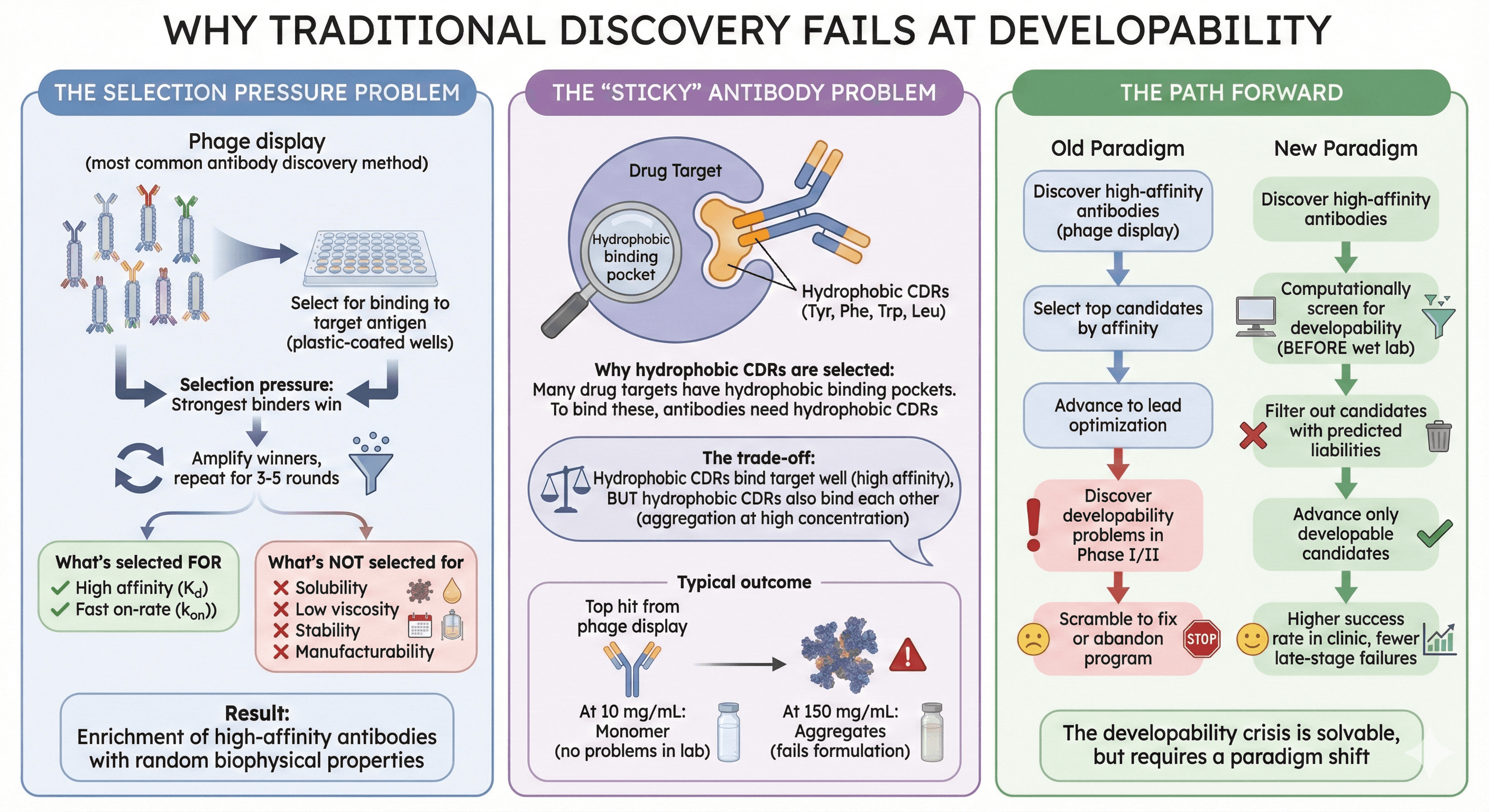

The Selection Pressure Problem

Phage display (most common antibody discovery method):

Display antibody fragments on phage surface

Select for binding to target antigen (plastic-coated wells)

Selection pressure: Strongest binders win

Amplify winners, repeat for 3-5 rounds

What's selected FOR:

High affinity (Kd)

Fast on-rate (kon)

What's NOT selected for:

Solubility (phage particles don't aggregate, so no selection pressure)

Low viscosity (not measured)

Stability (short-term selection, weeks not months)

Manufacturability (small-scale expression, not CHO bioreactor)

Result: Enrichment of high-affinity antibodies with random biophysical properties

The "Sticky" Antibody Problem

Why hydrophobic CDRs are selected:

Many drug targets have hydrophobic binding pockets (kinase ATP sites, GPCR ligand pockets)

To bind these pockets, antibodies need hydrophobic CDRs (Tyr, Phe, Trp, Leu)

Phage display strongly selects for these "sticky" CDRs (highest affinity)

The trade-off:

Hydrophobic CDRs bind target well (high affinity)

But hydrophobic CDRs also bind each other (aggregation at high concentration)

Typical outcome:

Top hit from phage display: Kd = 0.1 nM, CDR-H3 has 5 aromatic residues

At 10 mg/mL: Monomer (no problems in lab)

At 150 mg/mL: Aggregates (fails formulation)

The Path Forward

The developability crisis is solvable, but requires a paradigm shift:

Old paradigm:

Discover high-affinity antibodies (phage display)

Select top candidates by affinity

Advance to lead optimization

Discover developability problems in Phase I/II

Scramble to fix or abandon program

New paradigm:

Discover high-affinity antibodies

Computationally screen for developability (BEFORE wet lab)

Filter out candidates with predicted liabilities

Advance only developable candidates

Higher success rate in clinic, fewer late-stage failures

Key Takeaway

Developability is not optional. It's the difference between a $20B blockbuster drug and a $150M write-off.

The antibodies that make it to patients aren't just the ones with the highest affinity—they're the ones that can be manufactured at scale, stored for years, and injected painlessly.

Modern AI tools can predict these properties before you invest millions in clinical trials. The question is: Are you screening for developability early enough?

Ready to Assess Your Antibody's Developability?

If you have an antibody candidate and want to predict aggregation, viscosity, or stability issues before investing in expensive development, Orbion can help.

Orbion provides:

Aggregation hotspot prediction with mutation suggestions

Thermal stability optimization (ΔΔG predictions)

PTM liability detection (deamidation, oxidation, glycosylation)

Complete developability scorecard in minutes