Blog

Detergent-Free Membrane Protein Purification: Nanodiscs and Beyond

Dec 26, 2025

You've screened detergents. You found one that solubilizes your GPCR without aggregation. But there's a lingering concern: Is your protein really native-like in a detergent micelle? Are you losing activity? Could the detergent be interfering with your structural studies or functional assays?

Enter detergent-free purification methods: nanodiscs, SMALPs, and amphipols. These approaches keep membrane proteins in a native-like lipid environment (or a stabilizing polymer belt) without the complications of detergent micelles. Here's how they work, when to use them, and how to prepare samples for Cryo-EM.

Key Takeaways

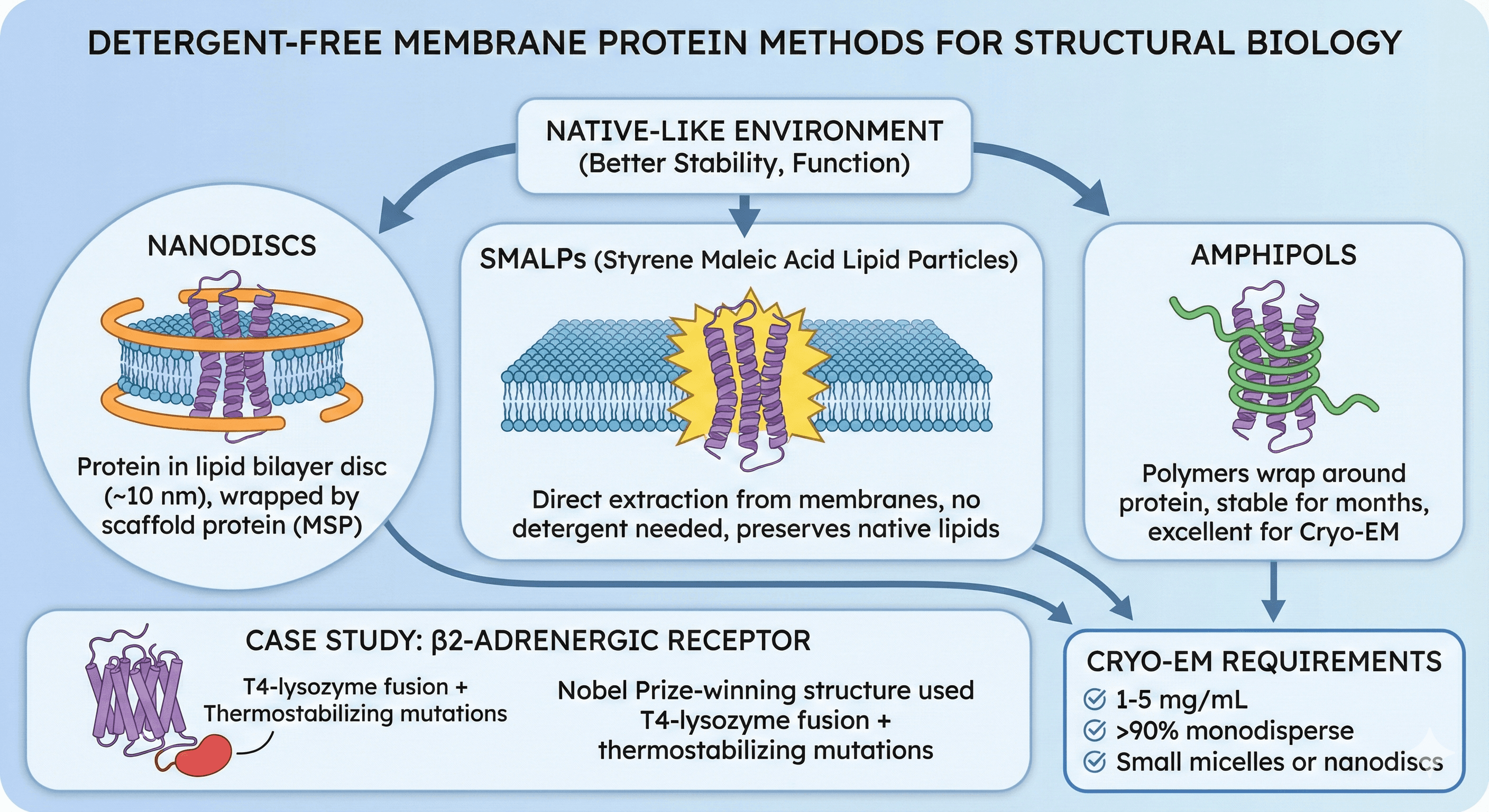

Detergent-free methods maintain native-like environment (better stability, function)

Nanodiscs: Protein in lipid bilayer disc (~10 nm), wrapped by scaffold protein (MSP)

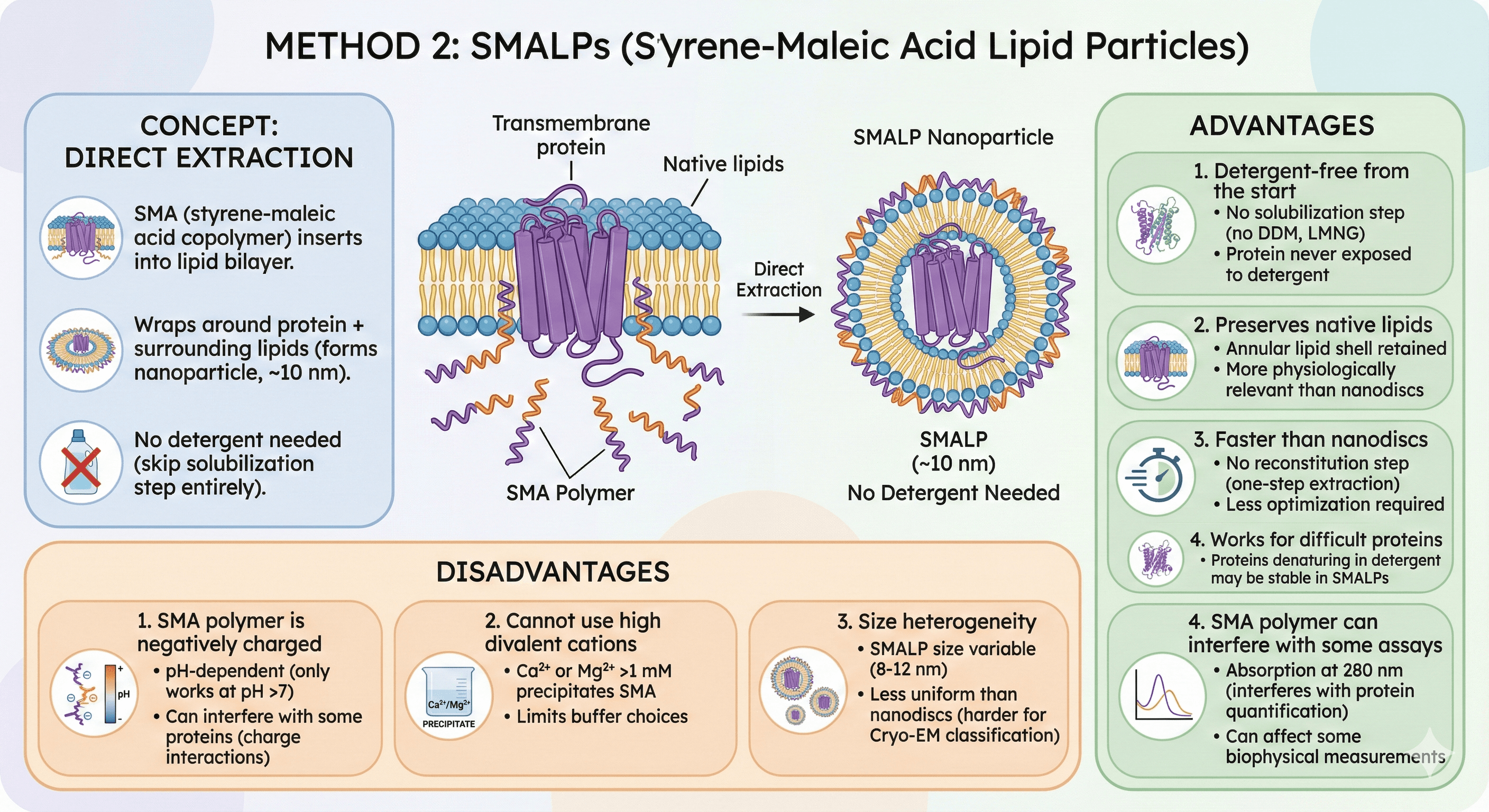

SMALPs: Direct extraction from membranes, no detergent needed, preserves native lipids

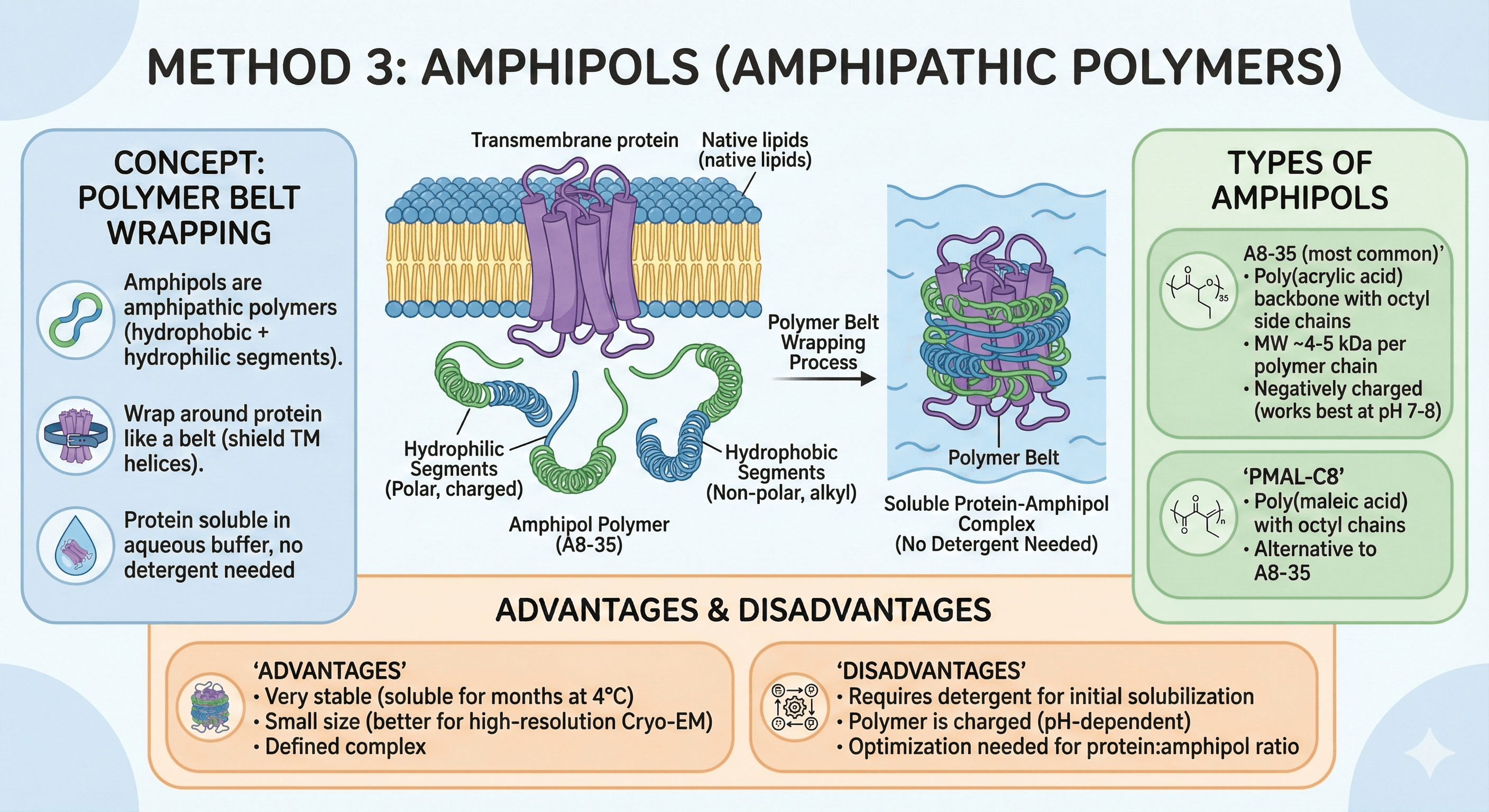

Amphipols: Polymers wrap around protein, stable for months, excellent for Cryo-EM

β2-adrenergic receptor: Nobel Prize-winning structure used T4-lysozyme fusion + thermostabilizing mutations

Cryo-EM requires: 1-5 mg/mL, >90% monodisperse, small micelles or nanodiscs

Why Detergent-Free Matters

Problems with Detergents

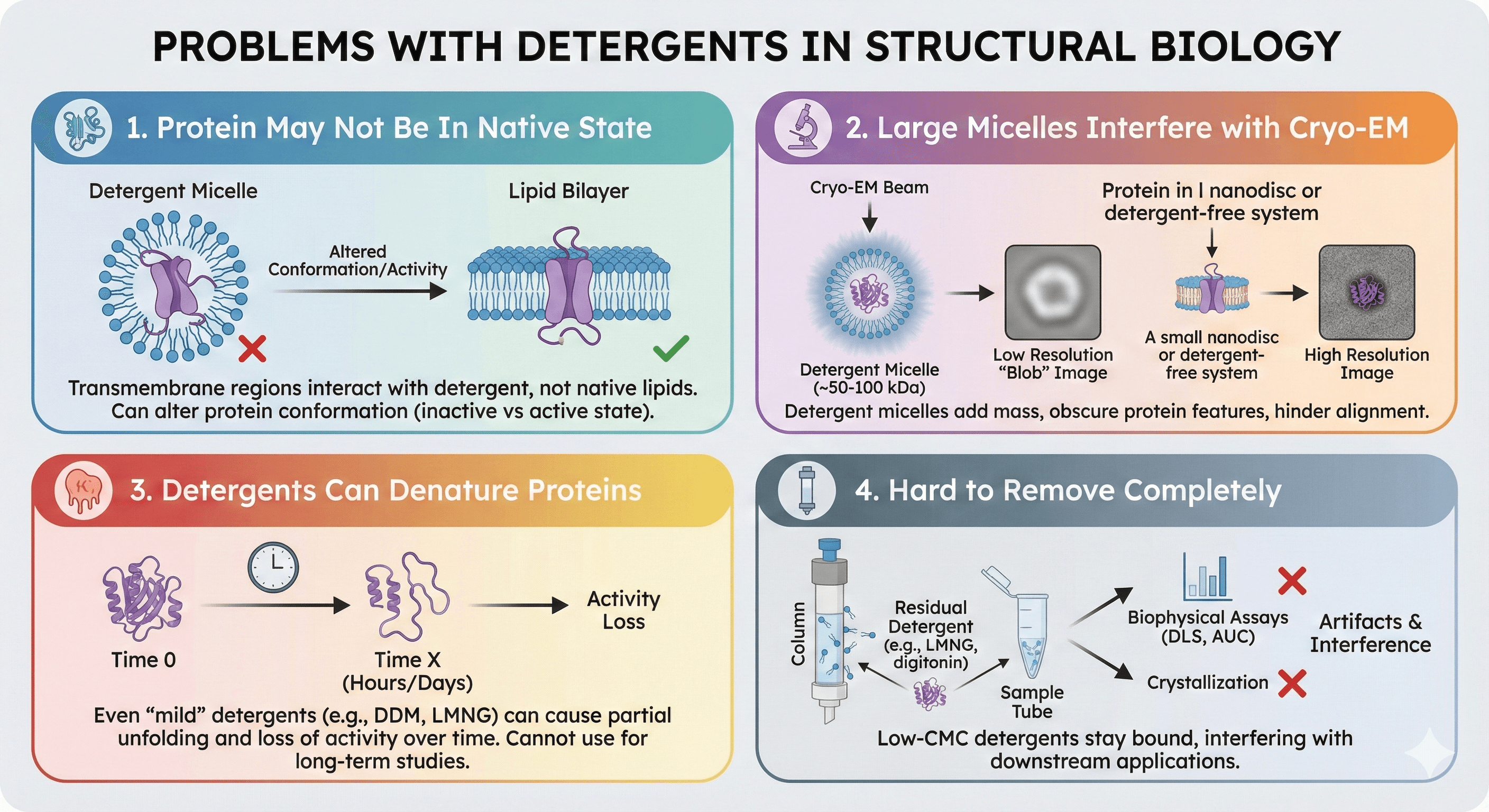

1. Protein may not be in native state

Detergent micelles ≠ lipid bilayer

Transmembrane regions interact with detergent, not native lipids

Can alter protein conformation (inactive state vs active state)

2. Large micelles interfere with Cryo-EM

Detergent micelles add ~50-100 kDa mass around protein

Obscures protein features (lower resolution)

Particle alignment difficult (micelle creates "blob")

3. Detergents can denature proteins

Even "mild" detergents (DDM, LMNG) cause partial unfolding for some proteins

Activity loss over time (hours to days)

Cannot use for long-term studies

4. Hard to remove completely

Low-CMC detergents (LMNG, digitonin) stay bound

Interferes with crystallization, biophysical assays

Detergent in sample causes artifacts (DLS, AUC)

Detergent-Free Approaches Solve These Problems

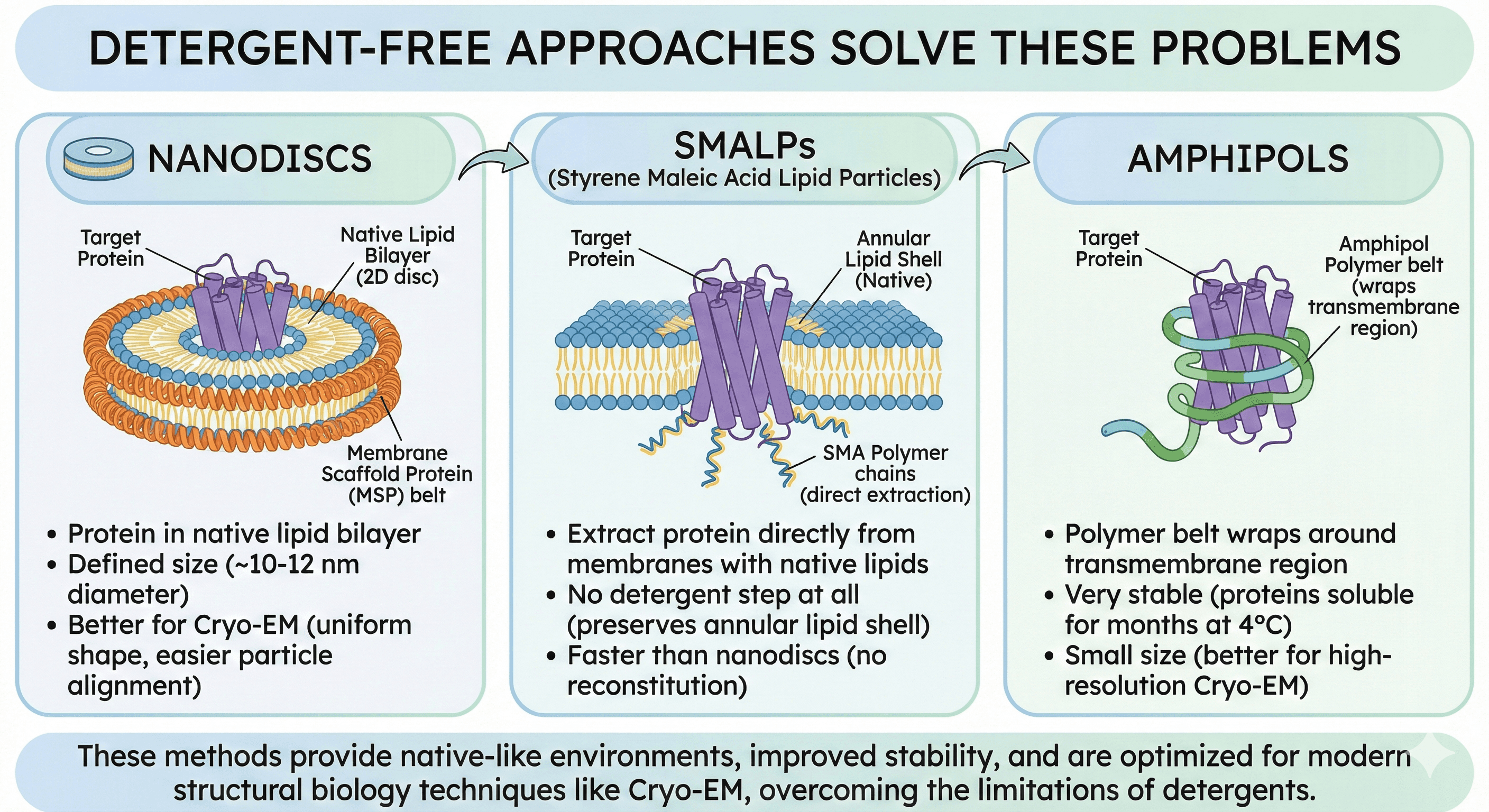

Nanodiscs:

Protein in native lipid bilayer (2D disc)

Defined size (~10-12 nm diameter)

Better for Cryo-EM (uniform shape, easier particle alignment)

SMALPs:

Extract protein directly from membranes with native lipids

No detergent step at all (preserves annular lipid shell)

Faster than nanodiscs (no reconstitution)

Amphipols:

Polymer belt wraps around transmembrane region

Very stable (proteins soluble for months at 4°C)

Small size (better for high-resolution Cryo-EM)

Method 1: Nanodiscs (Lipid Bilayer in a Disc)

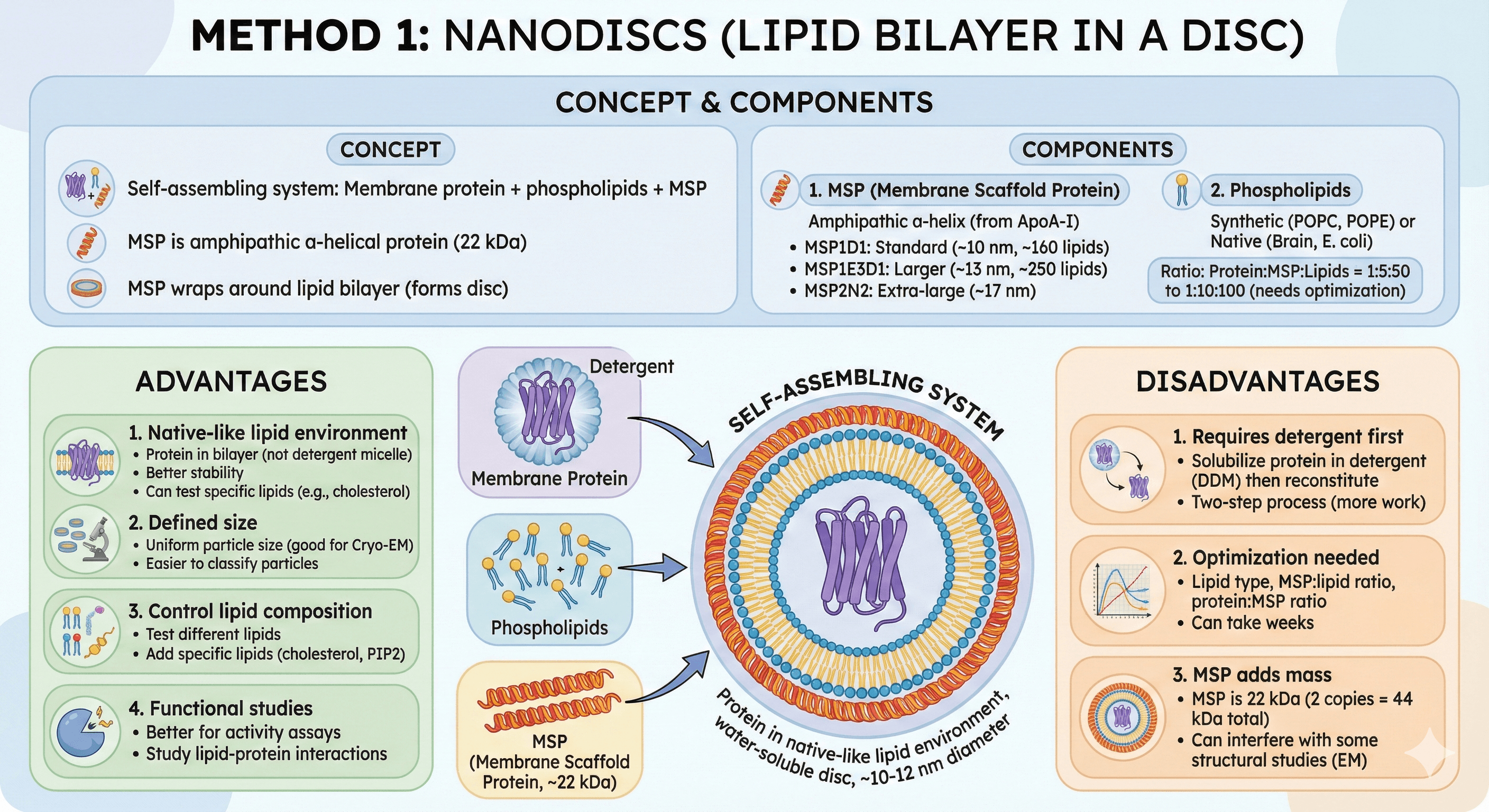

Concept

Self-assembling system:

Membrane protein + phospholipids + MSP (membrane scaffold protein)

MSP is an amphipathic α-helical protein (22 kDa)

MSP wraps around lipid bilayer (forms disc, ~10-12 nm diameter)

Protein sits in native-like lipid environment, but disc is water-soluble

Components

1. MSP (Membrane Scaffold Protein)

Amphipathic α-helix (derived from apolipoprotein A-I)

Wraps around edge of lipid bilayer

Sizes:

MSP1D1: Standard (~10 nm diameter, holds ~160 lipids)

MSP1E3D1: Larger (~13 nm diameter, holds ~250 lipids, for bigger proteins)

MSP2N2: Extra-large (~17 nm, for large complexes)

2. Phospholipids

Synthetic lipids: POPC, POPE, POPG, POPS

Native lipids: Brain polar lipids, E. coli polar lipids

Ratio: Protein:MSP:Lipids = 1:5:50 to 1:10:100 (needs optimization)

Advantages

1. Native-like lipid environment

Protein in bilayer (not detergent micelle)

Better stability, closer to physiological state

Can test specific lipid requirements (e.g., cholesterol for GPCRs)

2. Defined size

Uniform particle size (good for Cryo-EM)

Easier to classify particles (clear shape in EM images)

3. Control lipid composition

Test different lipids systematically

Add specific lipids (cholesterol, cardiolipin, PIP2)

4. Functional studies

Better for activity assays (native-like environment)

Can study lipid-protein interactions

Disadvantages

1. Requires detergent first

Solubilize protein in detergent (DDM)

Then reconstitute into nanodiscs

Two-step process (more work than SMALPs)

2. Optimization needed

Lipid type, MSP:lipid ratio, protein:MSP ratio

Can take weeks to optimize

3. MSP adds mass

MSP is 22 kDa (2 copies per disc = 44 kDa total)

Can interfere with some structural studies

Need to account for MSP mass in EM

Protocol: Nanodisc Reconstitution

Starting material: Protein purified in detergent (DDM, from Part 1)

Step 1: Prepare Components

Protein:

Concentrate to 5-10 mg/mL (in DDM-containing buffer)

Keep at 4°C

MSP:

Express MSP1D1 in E. coli (plasmid available from Addgene)

Purify by His-tag (MSP has N-terminal His-tag)

Store at -80°C in 20 mM Tris pH 7.5, 100 mM NaCl

Lipids:

POPC (1-palmitoyl-2-oleoyl-sn-glycero-3-phosphocholine) from Avanti Polar Lipids

Dissolve in chloroform (25 mg/mL stock)

Store at -20°C under argon

Step 2: Mix Components

Typical reaction (100 μL):

Protein: 1 μM (1 nmol)

MSP1D1: 10 μM (10 nmol, 10× excess)

POPC: 100 μM (100 nmol, 100× excess, ~100 lipids per nanodisc)

DDM: 0.5% (in buffer)

Buffer:

20 mM Tris pH 7.5, 150 mM NaCl, 10% glycerol

Calculation notes:

Ratio optimization: Test ratios of protein:MSP:lipids = 1:5:50, 1:10:100, 1:15:150

MSP excess ensures all protein is incorporated

Step 3: Remove Detergent (Critical Step)

Method: Bio-Beads SM-2 (polystyrene resin)

Add 0.5-1 g Bio-Beads per 1 mL reaction (wet weight)

Incubate overnight (12-16 hours) at 4°C with gentle rotation

Bio-Beads absorb DDM → nanodisc self-assembles as detergent is removed

Alternative: Dialysis

Dialyze against 1000× volume of detergent-free buffer

Change buffer 3-4 times (every 4-6 hours)

Slower than Bio-Beads, but works

Step 4: Remove Bio-Beads

Transfer reaction to new tube (leave Bio-Beads behind)

Or centrifuge briefly (1,000 × g, 5 min) and collect supernatant

Step 5: Purify Nanodiscs by SEC

Why: Separate protein-containing nanodiscs from empty nanodiscs

Column: Superdex 200 Increase 10/300 GL

Buffer: 20 mM Tris pH 7.5, 150 mM NaCl, 10% glycerol (no detergent)

Expected elution:

Protein-containing nanodiscs: Elute earlier (~12-14 mL, larger MW)

Empty nanodiscs: Elute later (~15-16 mL, smaller MW)

Collect: Fractions from protein-containing peak

Step 6: Characterization

TEM (Transmission Electron Microscopy):

Negative stain with uranyl acetate

Expected: Circular discs visible (~10-12 nm diameter)

Confirms nanodisc formation

SEC-MALS:

Measure MW of nanodisc

Expected: Protein MW + 2× MSP (44 kDa) + lipids (~120 kDa total for 50 kDa protein)

Activity assay:

Test ligand binding or transport activity

Compare to detergent-solubilized protein

Troubleshooting Nanodiscs

Problem: No protein in nanodiscs (empty nanodiscs only)

Cause: Wrong lipid:MSP ratio, or protein aggregated during reconstitution

Solution: Optimize ratio, add more protein, keep cold (4°C)

Problem: Heterogeneous sample (multiple peaks in SEC)

Cause: Multiple oligomeric states, or variable nanodisc sizes

Solution: Optimize MSP:lipid ratio, use size-defined MSP (MSP1E3D1 for larger proteins)

Problem: Protein inactive in nanodiscs

Cause: Wrong lipid type, or lipid:protein ratio too low

Solution: Test different lipids (add cholesterol for GPCRs, cardiolipin for respiratory complexes)

Method 2: SMALPs (Styrene-Maleic Acid Lipid Particles)

Concept

Direct extraction from membranes:

SMA (styrene-maleic acid copolymer) inserts into lipid bilayer

Wraps around protein + surrounding lipids (forms nanoparticle, ~10 nm)

No detergent needed (skip solubilization step entirely)

Advantages

1. Detergent-free from the start

No solubilization step (no DDM, no LMNG)

Protein never exposed to detergent

2. Preserves native lipids

Annular lipid shell around protein retained

More physiologically relevant than nanodiscs with synthetic lipids

3. Faster than nanodiscs

No reconstitution step (one-step extraction)

Less optimization required

4. Works for difficult proteins

Proteins that denature in detergent may be stable in SMALPs

Disadvantages

1. SMA polymer is negatively charged

pH-dependent (only works at pH >7)

Can interfere with some proteins (charge interactions)

2. Cannot use high divalent cations

Ca²⁺ or Mg²⁺ >1 mM precipitates SMA

Limits buffer choices

3. Size heterogeneity

SMALP size variable (8-12 nm)

Less uniform than nanodiscs (harder for Cryo-EM classification)

4. SMA polymer can interfere with some assays

Absorption at 280 nm (interferes with protein quantification)

Can affect some biophysical measurements

Protocol: SMALP Extraction

Starting material: Crude membranes (from Part 1, Stage 2)

Step 1: Add SMA Polymer to Membranes

Membranes:

Resuspend to 10 mg/mL total protein (in buffer)

SMA polymer:

Add to 2.5% (w/v) final concentration

Ratio: 1:2.5 (protein:SMA, typical starting point)

Buffer:

50 mM Tris pH 7.5 or 50 mM HEPES pH 7.5 (pH must be >7 for SMA to work)

150 mM NaCl

Protease inhibitors

No Ca²⁺ or Mg²⁺ >1 mM (precipitates SMA)

Incubate:

2 hours at room temperature (RT) or 4 hours at 4°C

Gentle mixing (rotator or nutator)

Step 2: Clarify

Centrifugation:

100,000 × g, 30 min, 4°C

Supernatant: Protein in SMALPs (solubilized) Pellet: Unsolubilized membrane (discard)

Step 3: Affinity Purification

Same as detergent protocol (Part 1), but no detergent in buffers:

Wash buffer:

50 mM Tris pH 7.5, 150 mM NaCl

20 mM imidazole

10% glycerol

No detergent

Elution buffer:

50 mM Tris pH 7.5, 150 mM NaCl

250 mM imidazole

10% glycerol

Step 4: SEC (Polishing)

Column: Superdex 200

Buffer: 20 mM Tris pH 7.5, 150 mM NaCl, 10% glycerol (no detergent)

Expected: Single peak (protein in SMALP)

Step 5: Characterization

TEM: Observe SMALP particles (circular, ~10 nm)

Activity assay: Test function (compare to detergent)

SEC-MALS: Measure MW (protein + SMA + lipids)

Troubleshooting SMALPs

Problem: Low solubilization efficiency (<20%)

Cause: SMA:protein ratio too low, or pH too low

Solution: Increase SMA (2.5% → 5%), check pH >7.5

Problem: Precipitate forms during incubation

Cause: Ca²⁺ or Mg²⁺ in buffer

Solution: Use Ca²⁺/Mg²⁺-free buffer, add EGTA (1 mM) to chelate residual Ca²⁺

Problem: Protein inactive in SMALPs

Cause: SMA polymer interferes with functional site

Solution: Try alternative polymers (DIBMA, SMA-QA with different charge properties)

Method 3: Amphipols (Amphipathic Polymers)

Concept

Polymer belt wraps around transmembrane region:

Amphipols are amphipathic polymers (hydrophobic + hydrophilic segments)

Wrap around protein like a belt (shield TM helices)

Protein soluble in aqueous buffer, no detergent needed

Types of Amphipols

A8-35 (most common):

Poly(acrylic acid) backbone with octyl side chains

MW ~4-5 kDa per polymer chain

Negatively charged (works best at pH 7-8)

PMAL-C8:

Poly(maleic acid) with octyl chains

Alternative to A8-35

Advantages

1. No CMC (don't form micelles)

Stay bound to protein (don't dialyze out)

Stable association

2. Very stable

Proteins remain soluble for months at 4°C

Better than detergents (no slow aggregation)

3. Small size

Amphipol belt is thin (~3-4 nm)

Better for high-resolution Cryo-EM (less obscuring)

4. Compatible with many biophysical techniques

NMR (smaller than detergent micelles)

Cryo-EM (excellent, minimal background)

Disadvantages

1. Expensive

~$100-200/g (more than most detergents)

2. Can be hard to remove

If you need to later (e.g., for lipid reconstitution), amphipols are difficult to remove

3. Can block functional sites

Polymer may sterically block binding sites or conformational changes

Not ideal for all functional assays

Protocol: Amphipol Exchange

Starting material: Protein in detergent (DDM or LMNG)

Step 1: Mix Protein with Amphipol

Ratio: 1:5 (protein:amphipol, weight ratio)

Example: 1 mg protein + 5 mg amphipol A8-35

Incubate: 2 hours at 4°C (gentle mixing)

Step 2: Remove Detergent

Method 1: Bio-Beads

Add Bio-Beads (0.5 g per mL)

Incubate overnight at 4°C

Bio-Beads absorb detergent → amphipol remains bound to protein

Method 2: Dialysis

Dialyze against amphipol-free buffer (1000× volume)

Change buffer 3-4 times

Step 3: Remove Free Amphipol (Optional)

SEC: Superdex 200

Protein-amphipol complex elutes earlier (higher MW)

Free amphipol elutes later

Step 4: Characterization

DLS: Measure particle size (Rh should be small, ~5-8 nm for 50 kDa protein)

SEC-MALS: Confirm MW (protein + amphipol)

Activity assay: Test if protein is functional in amphipols

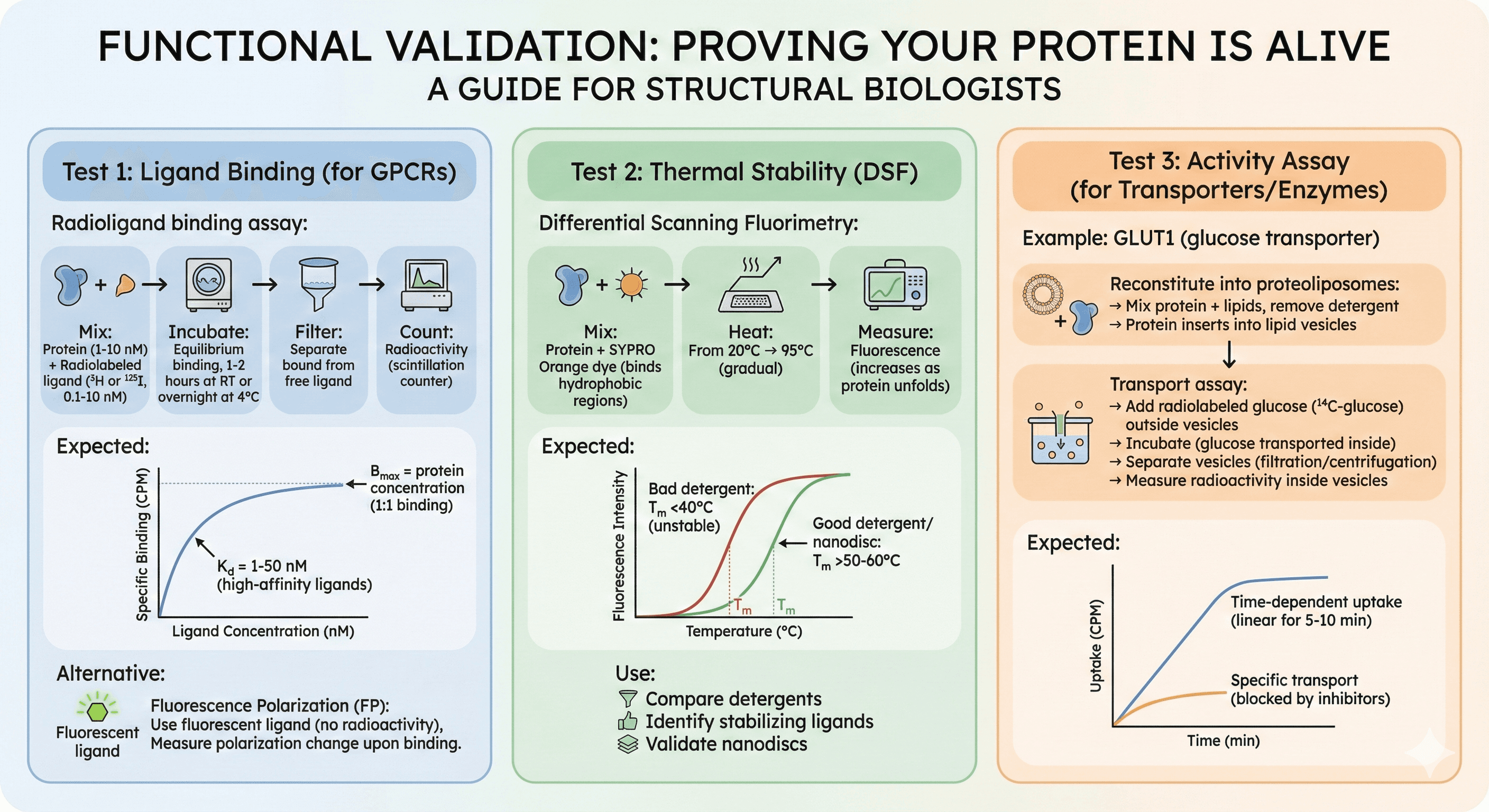

Functional Validation: Proving Your Protein Is Alive

Test 1: Ligand Binding (for GPCRs)

Radioligand binding assay:

Mix protein (1-10 nM) + radiolabeled ligand (³H or ¹²⁵I, 0.1-10 nM)

Incubate (equilibrium binding, 1-2 hours at RT or overnight at 4°C)

Filter (separate bound from free ligand)

Count radioactivity (scintillation counter)

Expected:

Specific binding: Kd = 1-50 nM (high-affinity ligands)

Bmax = protein concentration (1:1 binding)

Alternative: Fluorescence Polarization (FP)

Use fluorescent ligand (no radioactivity)

Measure polarization change upon binding

Test 2: Thermal Stability (DSF)

Differential Scanning Fluorimetry:

Mix protein + SYPRO Orange dye (binds hydrophobic regions)

Heat from 20°C → 95°C (gradual)

Measure fluorescence (increases as protein unfolds)

Expected:

Tm (melting temperature): Inflection point

Good detergent/nanodisc: Tm >50-60°C

Bad detergent: Tm <40°C (unstable)

Use: Compare detergents, identify stabilizing ligands, validate nanodiscs

Test 3: Activity Assay (for Transporters/Enzymes)

Example: GLUT1 (glucose transporter)

Reconstitute into proteoliposomes:

Mix protein + lipids, remove detergent

Protein inserts into lipid vesicles (liposomes)

Transport assay:

Add radiolabeled glucose (¹⁴C-glucose) outside vesicles

Incubate (glucose transported inside)

Separate vesicles (filtration or centrifugation)

Measure radioactivity inside vesicles

Expected:

Time-dependent uptake (linear for 5-10 min)

Specific transport (blocked by inhibitors)

Case Study: β2-Adrenergic Receptor (Nobel Prize-Winning Purification)

The Challenge

Target: β2-adrenergic receptor (GPCR, 7 TM helices)

Historical context:

GPCRs extremely difficult to crystallize (unstable, flexible)

No GPCR structure until 2007 (despite decades of effort)

The Solution (Brian Kobilka's Lab)

Expression: Sf9 insect cells, baculovirus (5-10 mg/L yield)

Construct Engineering (Critical for Success):

1. N-terminal truncation

Removed disordered region (residues 1-33)

Reduces flexibility

2. ICL3 replacement

Replaced flexible intracellular loop 3 (ICL3) with T4 lysozyme

T4-lysozyme acts as fiducial marker for crystallization (provides crystal contacts)

Rigidifies receptor

3. C-terminal truncation

Removed phosphorylation sites (residues 365-413)

Reduces heterogeneity

4. Thermostabilizing mutations

6 point mutations (identified by alanine scanning)

Increased Tm by ~20°C (from 40°C → 60°C)

Mutations: L48A, E122W, Y132G, R149L, Y219A, H296A

Purification:

1. Membrane preparation: Ultracentrifugation

2. Solubilization:

1% DDM + 0.2% CHS (cholesteryl hemisuccinate, stabilizing lipid)

3. Affinity:

Ni-NTA (His-tag at C-terminus)

4. Ligand binding:

Add alprenolol (inverse agonist, 10 μM)

Stabilizes inactive state (locks conformation)

5. SEC:

Superdex 200

Monodisperse peak (single, sharp)

6. Concentrate:

To 40-50 mg/mL (for crystallization)

Crystallization:

Lipidic cubic phase (LCP): Protein in monoolein lipid matrix

Crystals grown over weeks

X-ray diffraction: 2.4 Å resolution

Impact:

First high-resolution GPCR structure (2007, Nature)

Brian Kobilka awarded Nobel Prize (2012, with Robert Lefkowitz)

Enabled structure-based drug design for GPCRs (>500 drugs target GPCRs)

Key Lessons:

1. Construct engineering is critical

Truncations, fusions, thermostabilizing mutations = success

2. Ligand stabilization matters

Inverse agonist (alprenolol) locks receptor in stable conformation

Without ligand: Receptor is too flexible, cannot crystallize

3. Lipid matters

CHS (cholesteryl hemisuccinate) stabilizes GPCR

Mimics cholesterol (native lipid for GPCRs)

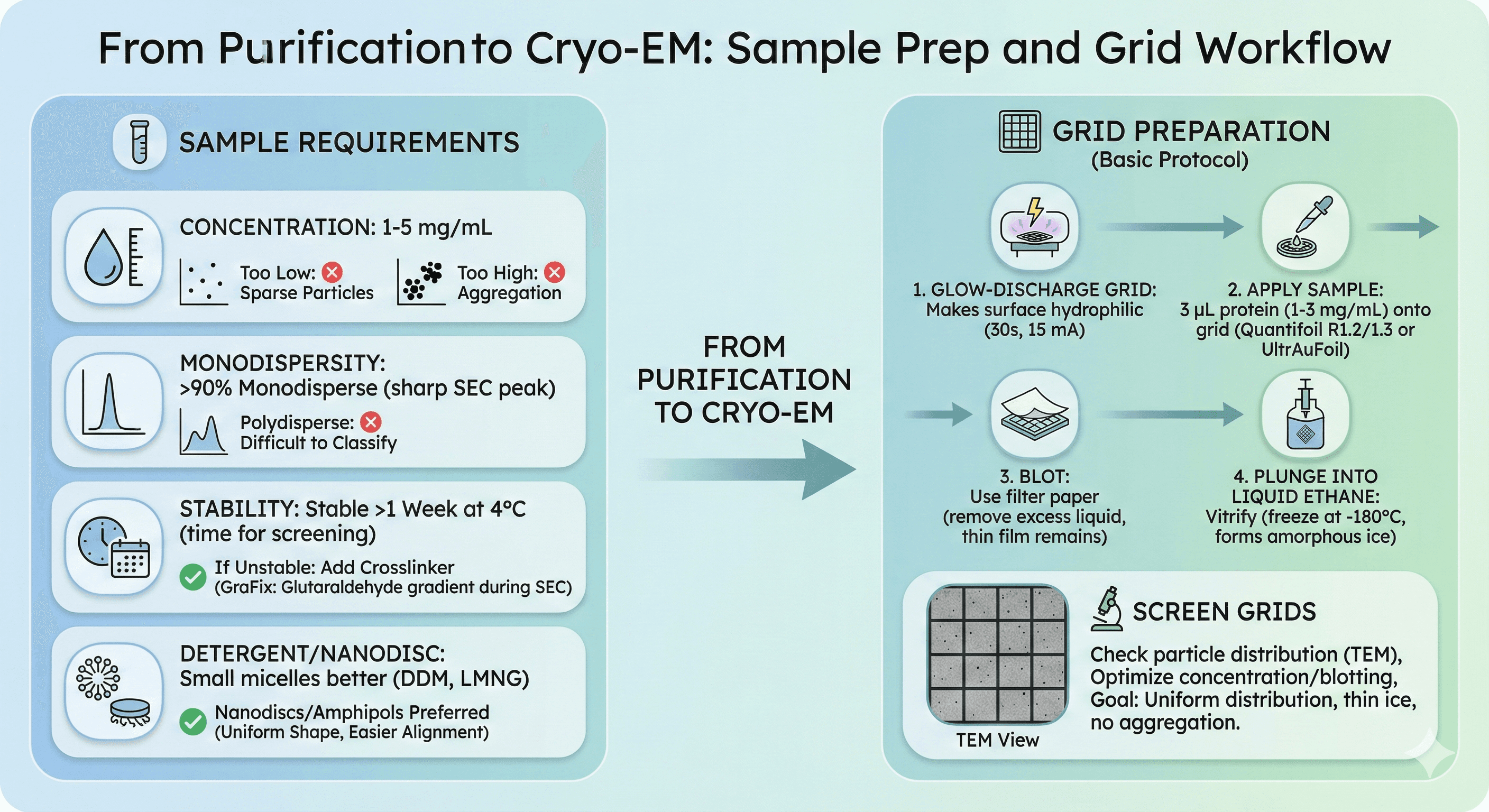

From Purification to Cryo-EM

Sample Requirements

Concentration:

1-5 mg/mL (optimal for grid preparation)

Too low: Particles sparse

Too high: Aggregation on air-water interface

Monodispersity:

>90% monodisperse (sharp SEC peak)

Polydisperse samples: Difficult to classify particles

Stability:

Stable >1 week at 4°C (time needed for grid screening)

If unstable: Add crosslinker (GraFix: glutaraldehyde gradient during SEC)

Detergent/nanodisc considerations:

Small micelles better: DDM, LMNG (vs Triton X-100, large)

Nanodiscs/amphipols preferred: Uniform shape, easier particle alignment

Grid Preparation (Basic Protocol)

1. Glow-discharge grid

Makes surface hydrophilic (30 seconds, 15 mA)

2. Apply sample

3 μL protein (1-3 mg/mL)

Onto grid (Quantifoil R1.2/1.3 or UltrAuFoil)

3. Blot

Use filter paper (remove excess liquid, thin film remains)

4. Plunge into liquid ethane

Vitrify (freeze at -180°C, forms amorphous ice)

Screen grids:

Check particle distribution (TEM)

Optimize concentration, blotting time

Goal: Uniform particle distribution, thin ice, no aggregation

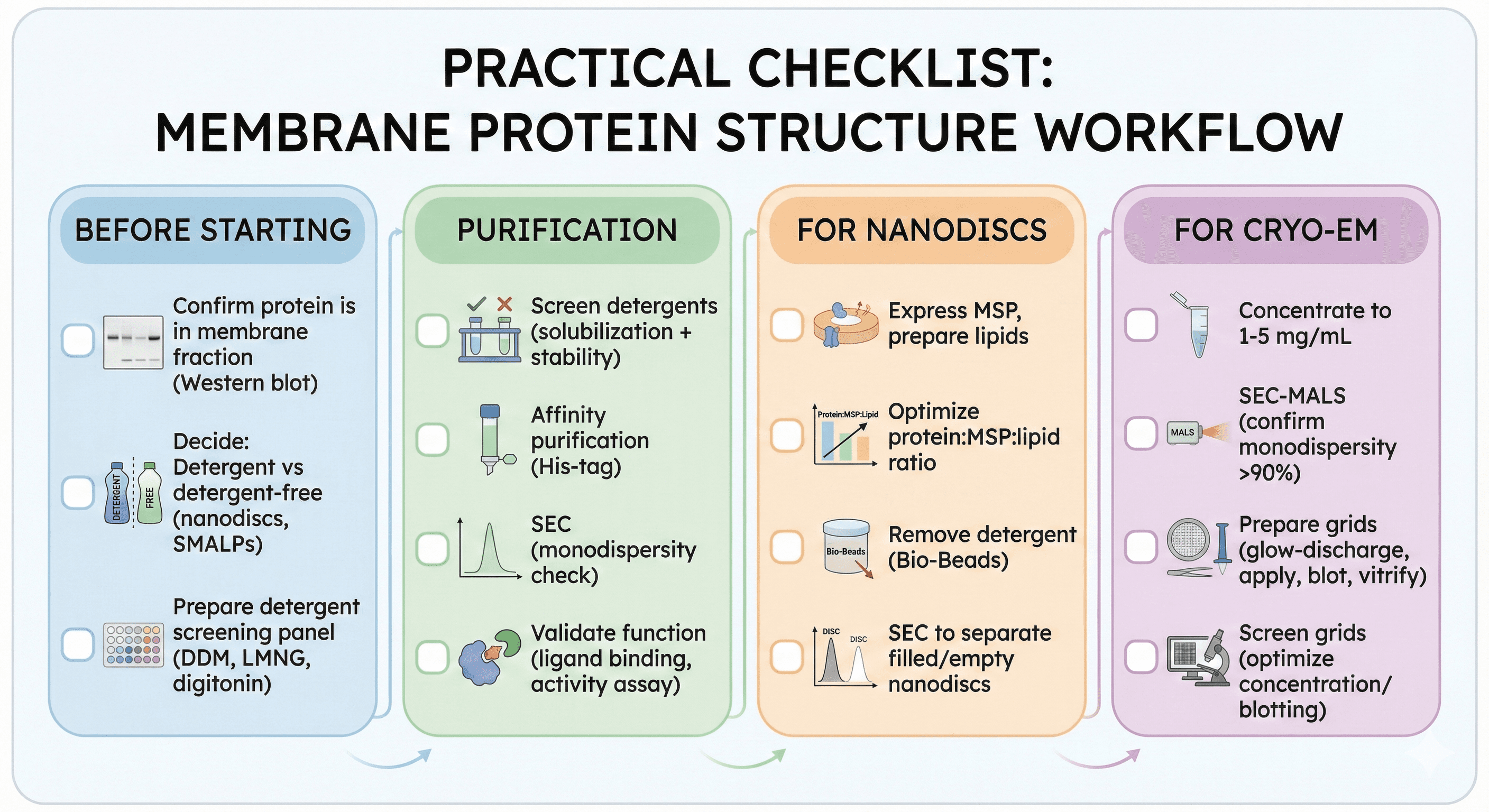

Practical Checklist

Before Starting

[ ] Confirm protein is in membrane fraction (Western blot)

[ ] Decide: Detergent vs detergent-free (nanodiscs, SMALPs)

[ ] Prepare detergent screening panel (DDM, LMNG, digitonin)

Purification

[ ] Screen detergents (solubilization + stability)

[ ] Affinity purification (His-tag)

[ ] SEC (monodispersity check)

[ ] Validate function (ligand binding, activity assay)

For Nanodiscs

[ ] Express MSP, prepare lipids

[ ] Optimize protein:MSP:lipid ratio

[ ] Remove detergent (Bio-Beads)

[ ] SEC to separate filled/empty nanodiscs

For Cryo-EM

[ ] Concentrate to 1-5 mg/mL

[ ] SEC-MALS (confirm monodispersity >90%)

[ ] Prepare grids (glow-discharge, apply, blot, vitrify)

[ ] Screen grids (optimize concentration/blotting)

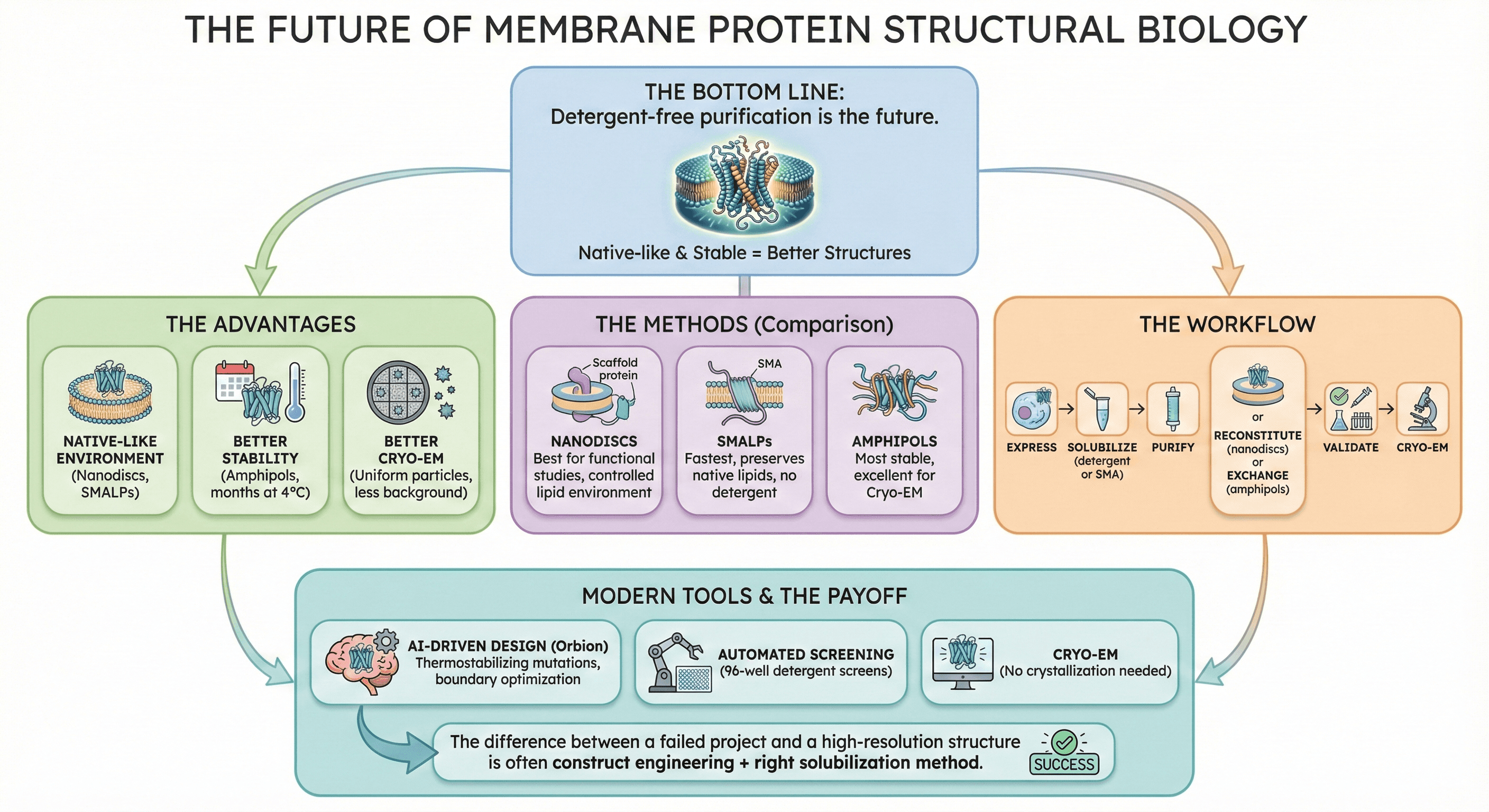

The Bottom Line

Detergent-free purification is the future of membrane protein structural biology.

The advantages:

Native-like environment (nanodiscs, SMALPs)

Better stability (amphipols, months at 4°C)

Better Cryo-EM (uniform particles, less background)

The methods:

Nanodiscs: Best for functional studies, controlled lipid environment

SMALPs: Fastest, preserves native lipids, no detergent

Amphipols: Most stable, excellent for Cryo-EM

The workflow:

Express → Solubilize (detergent or SMA) → Purify → Reconstitute (nanodiscs) or Exchange (amphipols) → Validate → Cryo-EM

Modern tools accelerate success:

AI-driven construct design (Orbion: thermostabilizing mutations, boundary optimization)

Automated screening (96-well detergent screens)

Cryo-EM (no crystallization needed)

The difference between a failed membrane protein project and a high-resolution structure is often construct engineering + right solubilization method.

Ready to Optimize Your Membrane Protein?

If you're struggling with membrane protein stability, expression, or construct design, Orbion can help.

Orbion provides:

Thermostabilizing mutation predictions (increase Tm, reduce aggregation)

Construct boundary design (truncate disordered regions, identify stable domains)

Membrane topology prediction (TM helices, loop regions, signal peptides)

Expression system recommendations (E. coli vs insect vs mammalian)

PTM prediction (glycosylation sites requiring specific expression systems)