Blog

Fixing Cryo-EM Sample Problems: Optimization Strategies & Workflows

Jan 7, 2026

We've diagnosed the 5 cryo-EM sample killers: preferred orientation, aggregation, denaturation, heterogeneity, and ice quality issues. Now comes the critical question: How do you fix it?

Nw, we'll cover systematic solutions, optimization workflows, modern AI-driven prediction, and a real-world case study of rescuing a failed ion channel project.

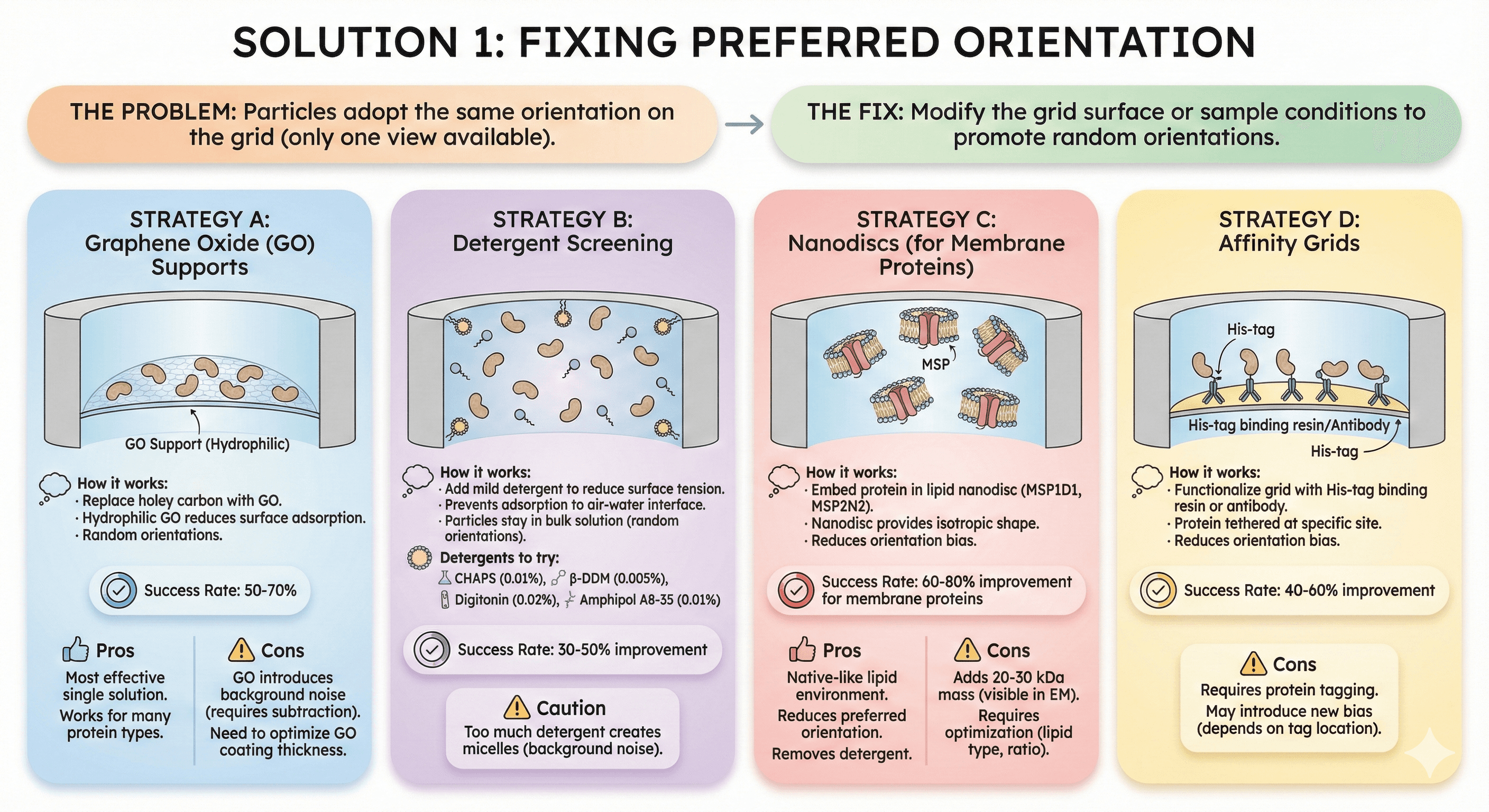

Solution 1: Fixing Preferred Orientation

The problem: Particles adopt the same orientation on the grid (only one view available).

The fix: Modify the grid surface or sample conditions to promote random orientations.

Strategy A: Graphene Oxide (GO) Supports

How it works:

Replace holey carbon with graphene oxide

GO is hydrophilic (reduces surface adsorption)

Particles adopt random orientations

Success rate: 50-70% of preferred orientation problems solved

Pros:

Most effective single solution

Works for many protein types

Cons:

GO introduces background noise (requires subtraction)

Need to optimize GO coating thickness

Strategy B: Detergent Screening

How it works:

Add mild detergent to reduce surface tension

Prevents adsorption to air-water interface

Particles stay in bulk solution (random orientations)

Detergents to try:

CHAPS (0.01%)

β-DDM (0.005%)

Digitonin (0.02%)

Amphipol A8-35 (0.01%)

Success rate: 30-50% improvement

Caution: Too much detergent creates micelles (background noise)

Strategy C: Nanodiscs (for Membrane Proteins)

How it works:

Embed protein in lipid nanodisc (MSP1D1, MSP2N2)

Nanodisc provides isotropic shape

Reduces orientation bias

Success rate: 60-80% improvement for membrane proteins

Pros:

Native-like lipid environment

Reduces preferred orientation

Removes detergent

Cons:

Adds 20-30 kDa mass (visible in EM)

Requires optimization (lipid type, ratio)

Strategy D: Affinity Grids

How it works:

Functionalize grid with His-tag binding resin or antibody

Protein tethered at specific site

Reduces orientation bias

Success rate: 40-60% improvement

Cons:

Requires protein tagging

May introduce new bias (depends on tag location)

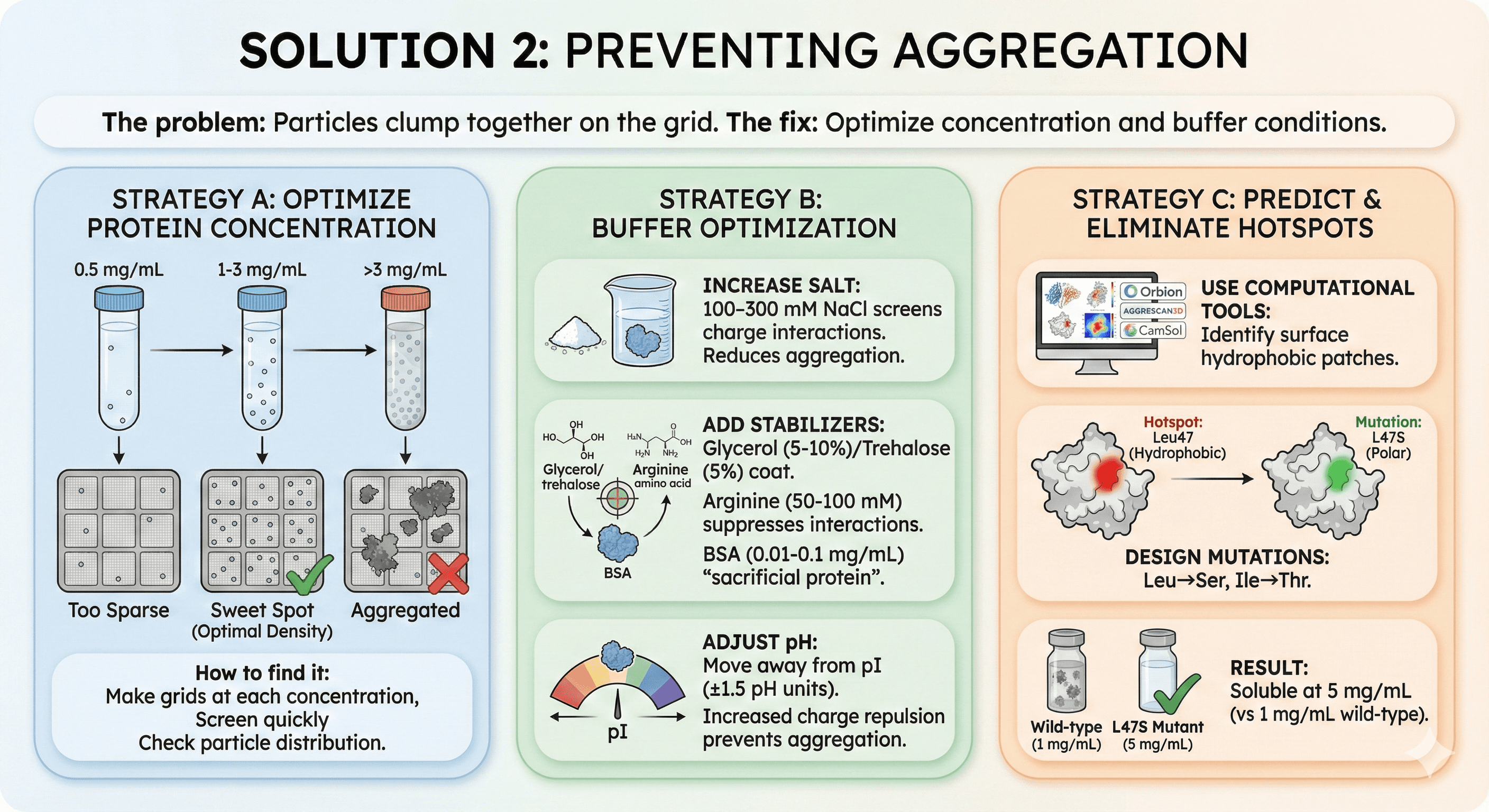

Solution 2: Preventing Aggregation

The problem: Particles clump together on the grid.

The fix: Optimize concentration and buffer conditions.

Strategy A: Optimize Protein Concentration

Test range: 0.5, 1, 2, 3 mg/mL

Sweet spot: High enough for particle density, low enough to avoid aggregation Typical optimal: 1-3 mg/mL for most proteins

How to find it:

Make grids at each concentration

Screen quickly

Check particle distribution

Strategy B: Buffer Optimization

Increase salt:

100-300 mM NaCl screens charge interactions

Reduces aggregation

Add stabilizers:

Glycerol (5-10%) or trehalose (5%)

Arginine (50-100 mM) suppresses protein-protein interactions

BSA (0.01-0.1 mg/mL) as "sacrificial protein"

Adjust pH:

Move away from pI (±1.5 pH units)

Increased charge repulsion prevents aggregation

Strategy C: Predict and Eliminate Aggregation Hotspots

Use computational tools:

Orbion, AGGRESCAN3D, CamSol

Identify surface hydrophobic patches

Design mutations (Leu→Ser, Ile→Thr)

Example:

Hotspot: Leu47 on surface

Mutation: L47S

Result: Soluble at 5 mg/mL (vs 1 mg/mL wild-type)

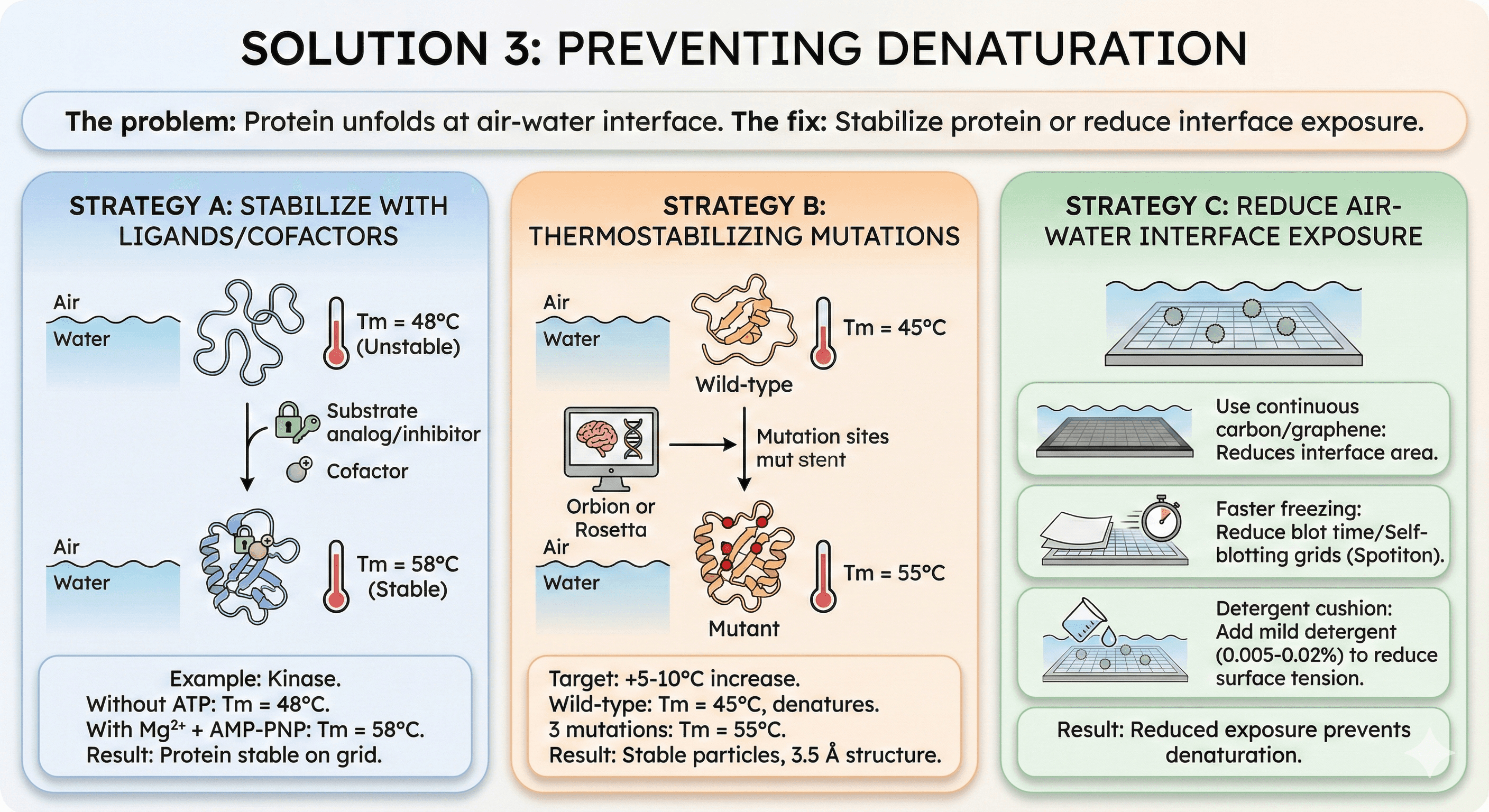

Solution 3: Preventing Denaturation

The problem: Protein unfolds at air-water interface.

The fix: Stabilize protein or reduce interface exposure.

Strategy A: Stabilize with Ligands/Cofactors

Add saturating ligand:

Substrate analog, inhibitor, or cofactor

Stabilizes conformation

Increases Tm

Example: Kinase

Without ATP: Tm = 48°C

With Mg²⁺ + AMP-PNP: Tm = 58°C

Result: Protein stable on grid

Strategy B: Thermostabilizing Mutations

Design mutations to increase Tm:

Target: +5-10°C increase

Use Orbion or Rosetta

Stable proteins resist denaturation

Example:

Wild-type: Tm = 45°C, denatures on grid

3 mutations (predicted by Orbion): Tm = 55°C

Result: Stable particles, 3.5 Å structure

Strategy C: Reduce Air-Water Interface Exposure

Use continuous carbon:

Reduces interface area

Or graphene/graphene oxide

Faster freezing:

Reduce blot time (less time at interface)

Self-blotting grids (Spotiton)

Detergent cushion:

Add mild detergent (0.005-0.02%)

Reduces surface tension

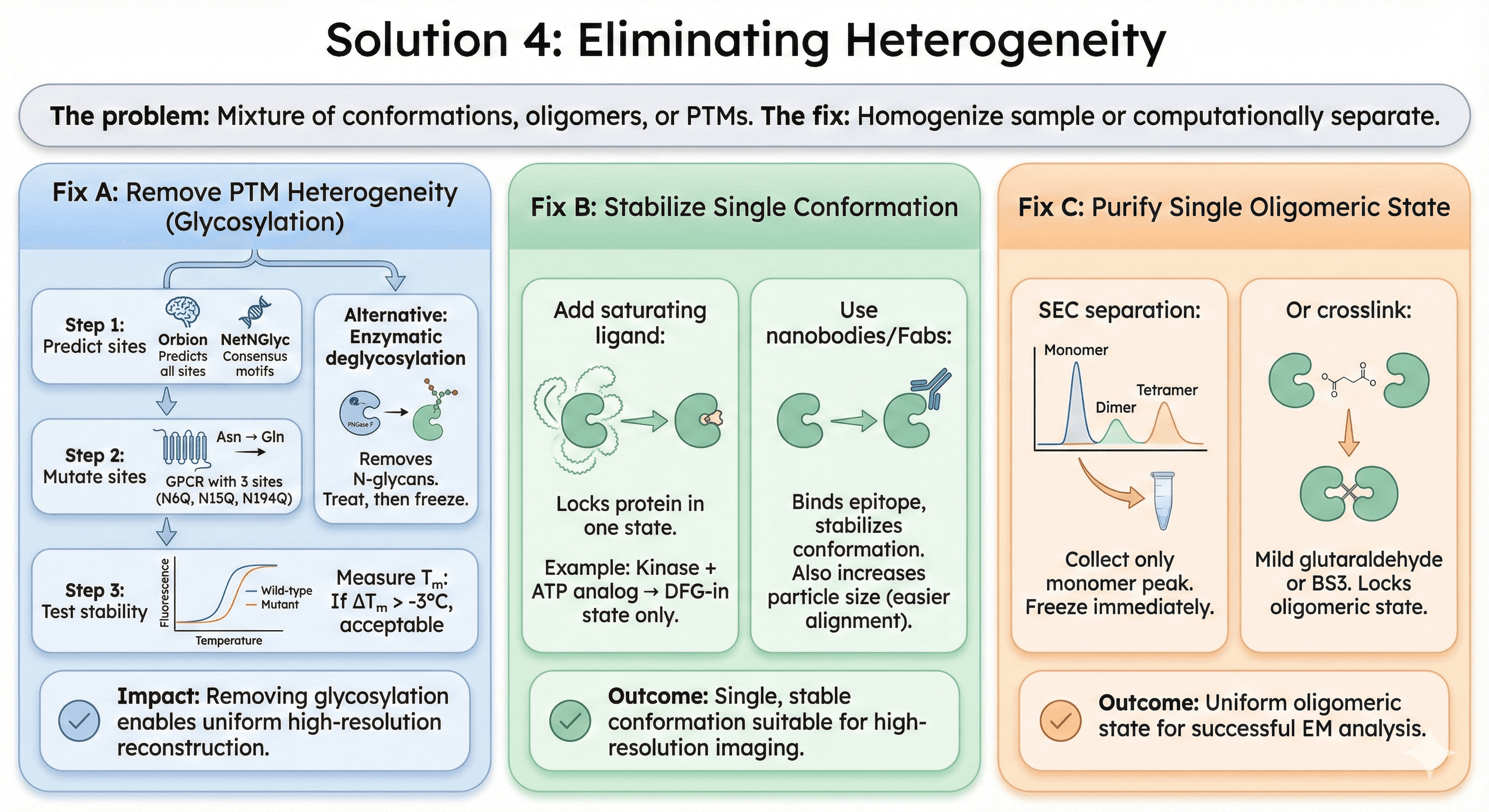

Solution 4: Eliminating Heterogeneity

The problem: Mixture of conformations, oligomers, or PTMs.

The fix: Homogenize sample or computationally separate.

Fix A: Remove PTM Heterogeneity

For glycosylation:

Step 1: Predict sites

Use Orbion (predicts all glycosylation sites)

Or NetNGlyc (free, consensus motifs)

Step 2: Mutate sites

Asn → Gln (blocks N-glycosylation)

Example: GPCR with 3 sites (N6Q, N15Q, N194Q)

Step 3: Test stability

Measure Tm: If ΔTm > -3°C, acceptable

Alternative: Enzymatic deglycosylation

PNGase F removes N-glycans

Treat protein, then freeze for EM

Impact: Removing glycosylation enables uniform high-resolution reconstruction

Fix B: Stabilize Single Conformation

Add saturating ligand:

Locks protein in one state

Example: Kinase + ATP analog → DFG-in state only

Use nanobodies/Fabs:

Binds epitope, stabilizes conformation

Also increases particle size (easier alignment)

Fix C: Purify Single Oligomeric State

SEC separation:

Collect only monomer peak

Freeze immediately

Or crosslink:

Mild glutaraldehyde or BS3

Locks oligomeric state

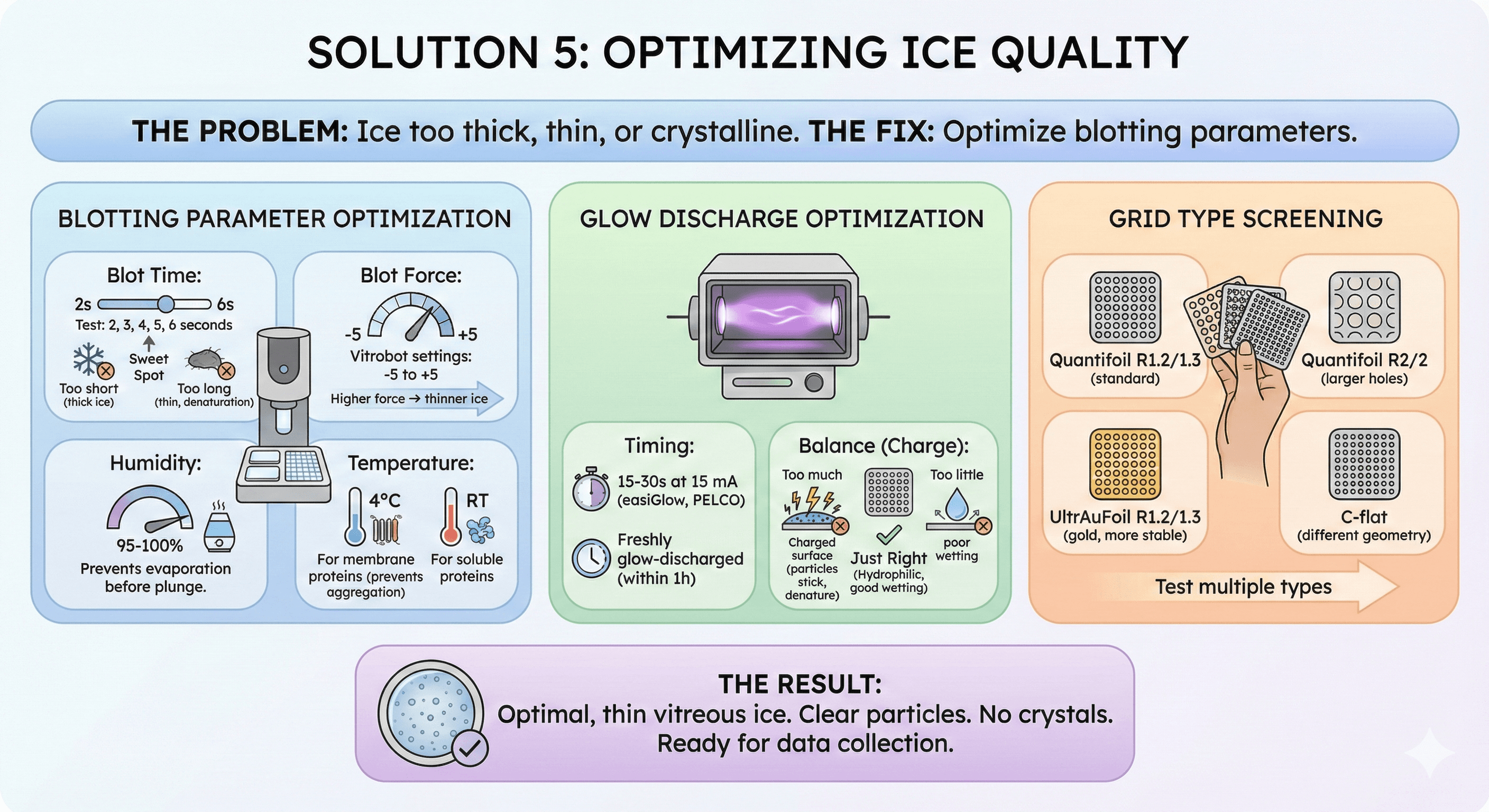

Solution 5: Optimizing Ice Quality

The problem: Ice too thick, thin, or crystalline.

The fix: Optimize blotting parameters.

Blotting Parameter Optimization

Blot time:

Test: 2, 3, 4, 5, 6 seconds

Too short → thick ice

Too long → thin ice, denaturation

Blot force:

Vitrobot settings: -5 to +5

Higher force → thinner ice

Humidity:

95-100% prevents evaporation before plunge

Temperature:

4°C for membrane proteins (prevents aggregation)

Room temperature for soluble proteins

Glow Discharge Optimization

Timing:

15-30 seconds at 15 mA (easiGlow, PELCO)

Freshly glow-discharged (within 1 hour)

Too much:

Charged surface (particles stick, denature)

Too little:

Hydrophobic surface (poor wetting)

Grid Type Screening

Test multiple types:

Quantifoil R1.2/1.3 (standard)

Quantifoil R2/2 (larger holes)

UltrAuFoil R1.2/1.3 (gold, more stable)

C-flat (different geometry)

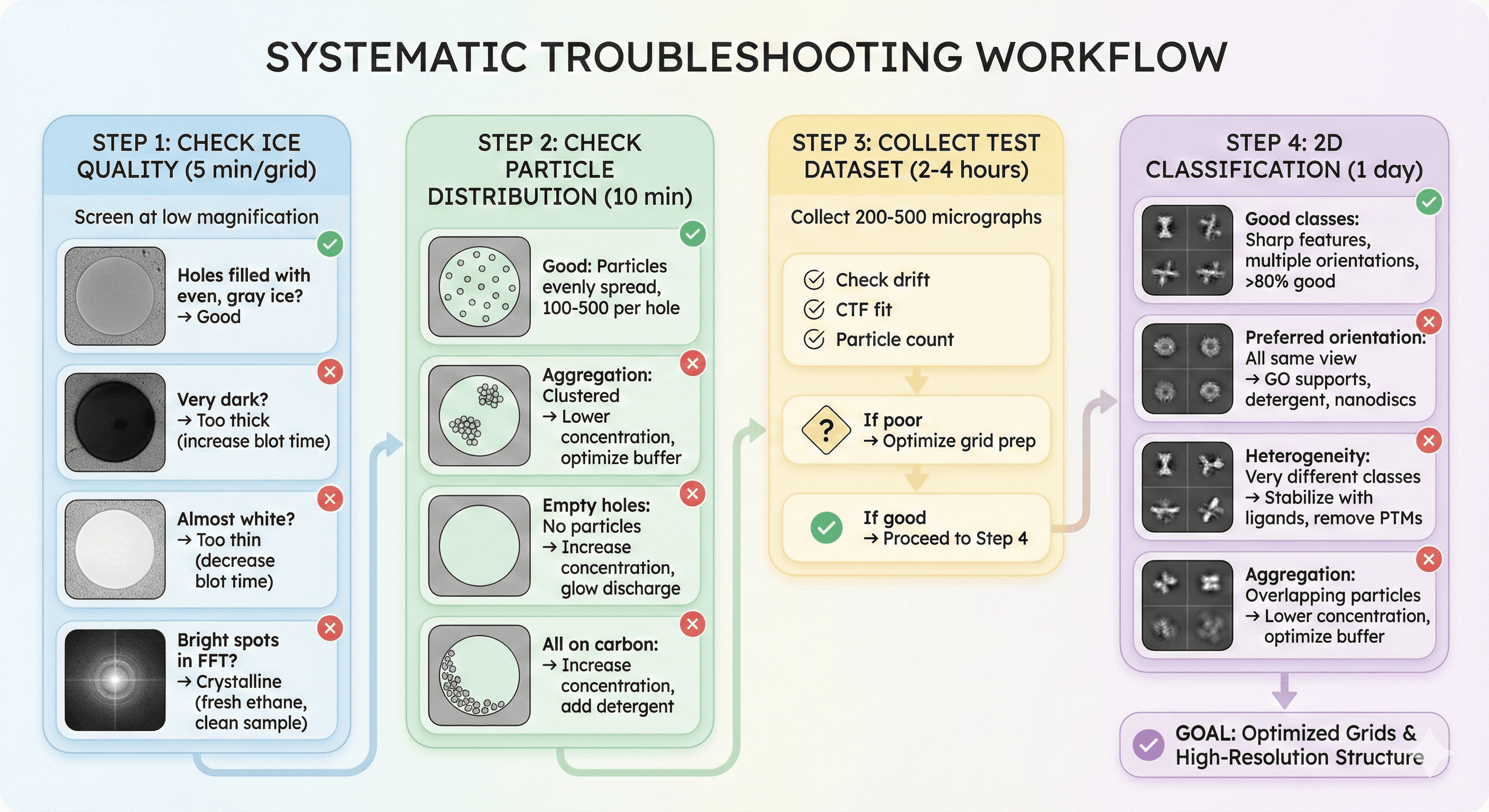

Systematic Troubleshooting Workflow

Step 1: Check Ice Quality (5 min/grid)

Screen at low magnification:

Holes filled with even, gray ice? → Good

Very dark? → Too thick (increase blot time)

Almost white? → Too thin (decrease blot time)

Bright spots in FFT? → Crystalline (fresh ethane, clean sample)

Step 2: Check Particle Distribution (10 min)

Good: Particles evenly spread, 100-500 per hole Aggregation: Clustered → Lower concentration, optimize buffer Empty holes: No particles → Increase concentration, glow discharge All on carbon: → Increase concentration, add detergent

Step 3: Collect Test Dataset (2-4 hours)

Collect 200-500 micrographs:

Check drift, CTF fit, particle count

If poor → Optimize grid prep

Step 4: 2D Classification (1 day)

Good classes: Sharp features, multiple orientations, >80% good Preferred orientation: All same view → GO supports, detergent, nanodiscs Heterogeneity: Very different classes → Stabilize with ligands, remove PTMs Aggregation: Overlapping particles → Lower concentration, optimize buffer

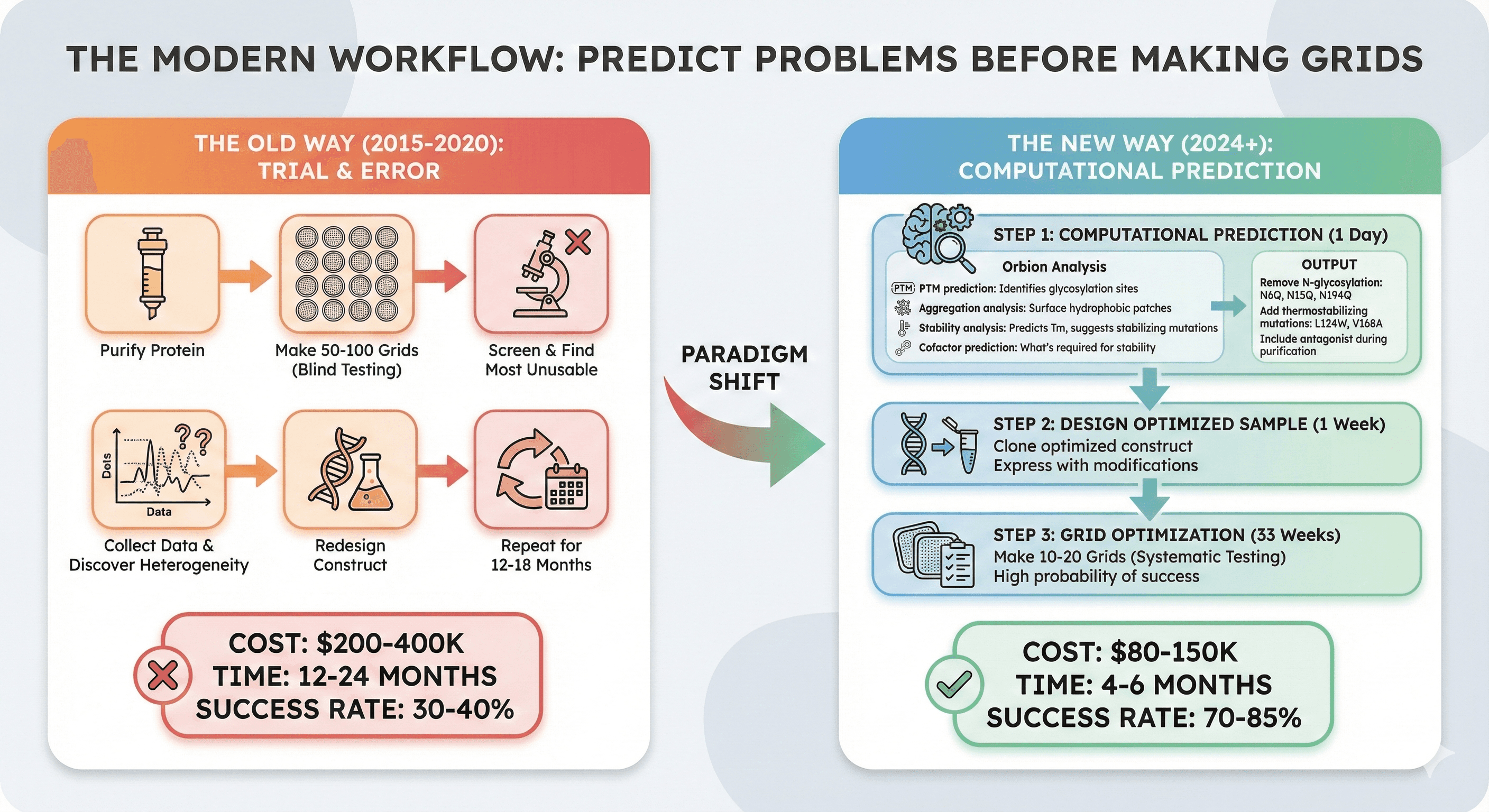

The Modern Workflow: Predict Problems Before Making Grids

The old way (2015-2020):

Purify protein

Make 50-100 grids (blind testing)

Screen → Find most unusable

Collect data → Discover heterogeneity

Redesign construct

Repeat for 12-18 months

Cost: $200-400K, 12-24 months

The new way (2024+):

Step 1: Computational Prediction (1 day)

Orbion analysis:

PTM prediction: Identifies glycosylation sites

Aggregation analysis: Surface hydrophobic patches

Stability analysis: Predicts Tm, suggests stabilizing mutations

Cofactor prediction: What's required for stability

Output:

"Remove N-glycosylation: N6Q, N15Q, N194Q"

"Add thermostabilizing mutations: L124W, V168A"

"Include antagonist during purification"

Step 2: Design Optimized Sample (1 week)

Clone optimized construct

Express with modifications

Step 3: Grid Optimization (3 weeks)

Make 10-20 grids (systematic testing)

High probability of success

Cost: $80-150K, 4-6 months

Success rate: 70-85% (vs 30-40% traditional)

Case Study: Rescuing a Failed Ion Channel

The Challenge

Target: Pentameric ligand-gated ion channel

Initial attempt (2018-2019):

Construct: Full-length

Expression: Sf9 cells, detergent-solubilized

Grids: 80 made

Data: 3 sessions ($150K)

Result: Cannot refine beyond 6 Å

Diagnosis: Severe preferred orientation (>95% top-down), glycosylation heterogeneity

The Rescue (with Orbion)

Step 1: PTM analysis

Orbion predicts 4 N-glycosylation sites per subunit (20 total)

Fix: Mutate all (N45Q, N89Q, N138Q, N276Q)

Step 2: Construct optimization

AlphaFold: C-terminus (450-478) disordered

Intracellular loop (340-385) flexible

Fix: Truncate C-terminus, stabilize loop (V351A, L367S, F378A)

Step 3: Preferred orientation strategy

Fix: Use nanodiscs (MSP1D1, POPC:POPG 3:1)

Isotropic shape reduces orientation bias

Step 4: Stability optimization

Orbion predicts agonist stabilizes open state

Fix: Add saturating agonist (100 μM)

Final Construct & Strategy

Residues: 1-449 (truncated)

Mutations: N45Q, N89Q, N138Q, N276Q, V351A, L367S, F378A

Nanodisc reconstitution

Agonist-bound

Results

Expression: 4 mg/L (2× improvement)

Tm: 62°C (+8°C)

Grids: 15 made, first grid showed good particles

Preferred orientation: Solved (angular distribution uniform)

Data: Single session (3 days)

Processing: 800,000 particles

Final: 2.9 Å structure

Cost: $60K, 5 months Outcome: Structure published

Lesson: Computational prediction identified all problems before grid optimization.

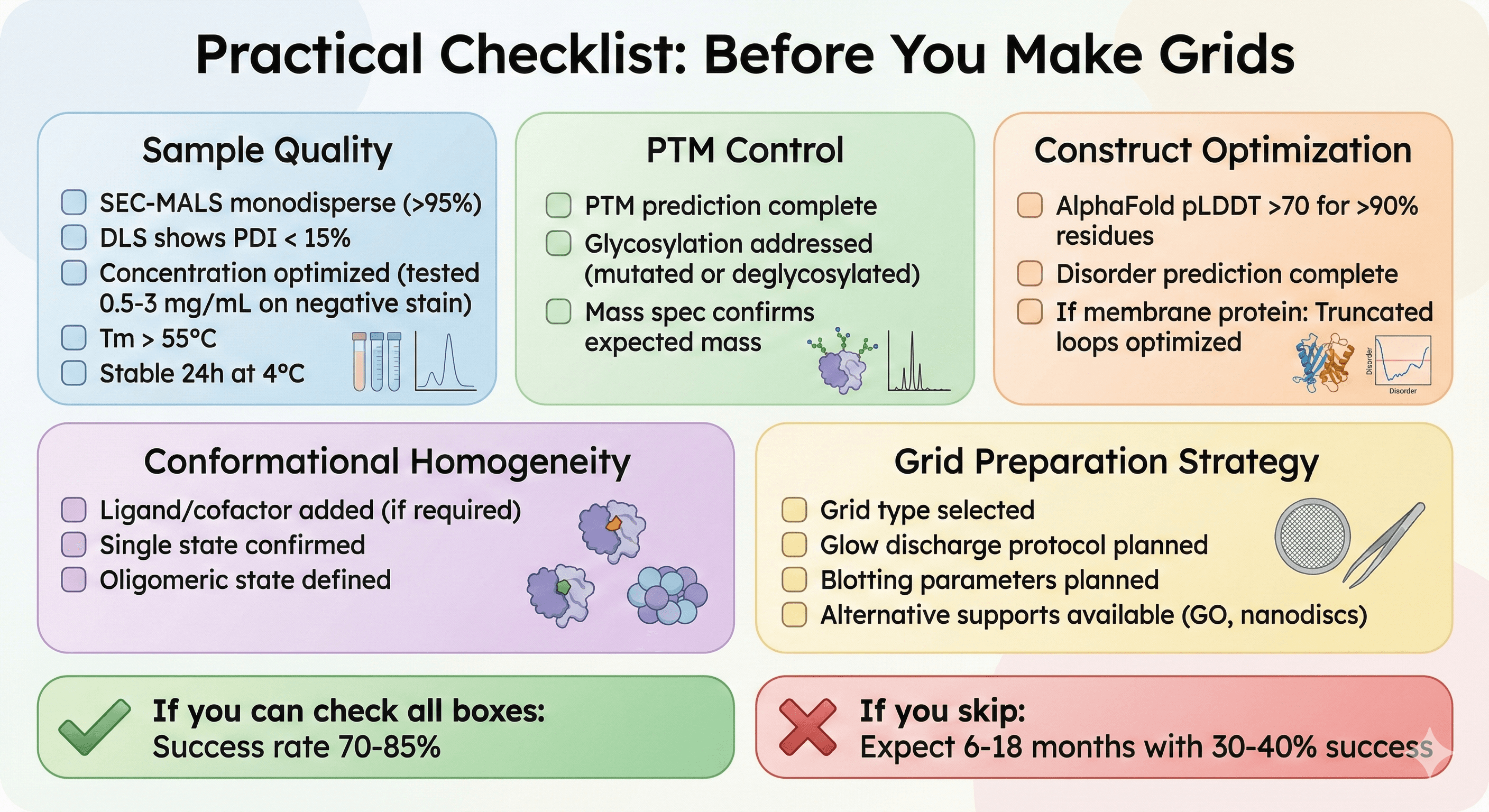

Practical Checklist: Before You Make Grids

☐ Sample Quality

[ ] SEC-MALS monodisperse (>95%)

[ ] DLS shows PDI < 15%

[ ] Concentration optimized (tested 0.5-3 mg/mL on negative stain)

[ ] Tm > 55°C

[ ] Stable 24h at 4°C

☐ PTM Control

[ ] PTM prediction complete

[ ] Glycosylation addressed (mutated or deglycosylated)

[ ] Mass spec confirms expected mass

☐ Construct Optimization

[ ] AlphaFold pLDDT >70 for >90% residues

[ ] Disorder prediction complete

[ ] If membrane protein: Truncated loops optimized

☐ Conformational Homogeneity

[ ] Ligand/cofactor added (if required)

[ ] Single state confirmed

[ ] Oligomeric state defined

☐ Grid Preparation Strategy

[ ] Grid type selected

[ ] Glow discharge protocol planned

[ ] Blotting parameters planned

[ ] Alternative supports available (GO, nanodiscs)

If you can check all boxes: Success rate 70-85%

If you skip: Expect 6-18 months with 30-40% success

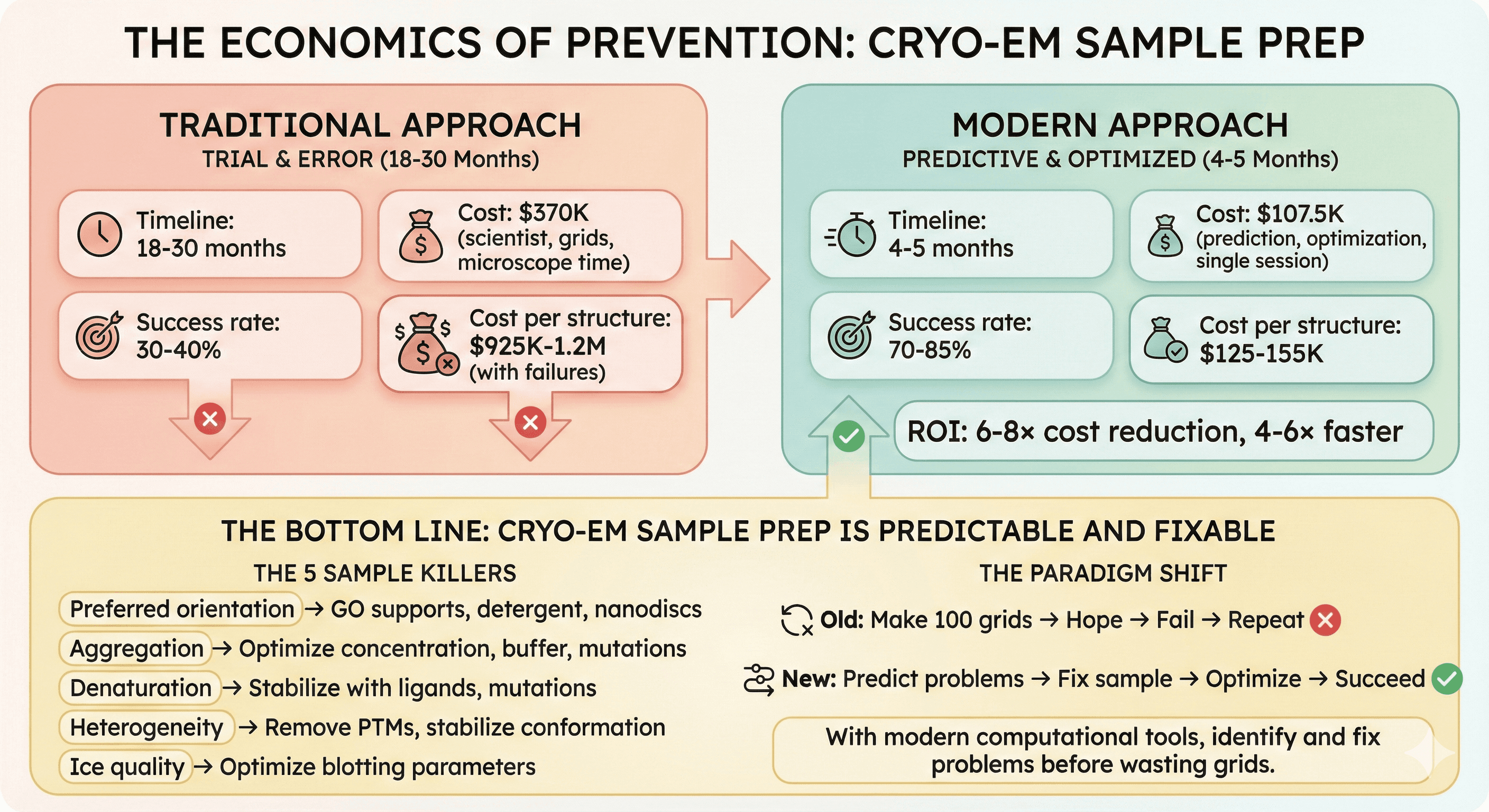

The Economics of Prevention

Traditional Approach

Timeline: 18-30 months Cost: $370K (scientist, grids, microscope time) Success rate: 30-40% Cost per structure: $925K-1.2M (with failures)

Modern Approach

Timeline: 4-5 months Cost: $107.5K (prediction, optimization, single session) Success rate: 70-85% Cost per structure: $125-155K

ROI: 6-8× cost reduction, 4-6× faster

The Bottom Line

Cryo-EM sample preparation is predictable and fixable.

The 5 sample killers:

Preferred orientation → GO supports, detergent, nanodiscs

Aggregation → Optimize concentration, buffer, mutations

Denaturation → Stabilize with ligands, mutations

Heterogeneity → Remove PTMs, stabilize conformation

Ice quality → Optimize blotting parameters

The paradigm shift:

Old: Make 100 grids → Hope → Fail → Repeat

New: Predict problems → Fix sample → Optimize → Succeed

With modern computational tools, identify and fix problems before wasting grids.

Ready to Optimize Your Cryo-EM Sample?

If you're preparing for cryo-EM, Orbion can identify potential problems before you make your first grid.

Orbion provides:

Complete PTM landscape (glycosylation causing heterogeneity)

Construct optimization (disorder, flexible loops)

Aggregation hotspot prediction

Stability optimization (thermostabilizing mutations)

Membrane topology analysis (for nanodiscs)

From sequence to cryo-EM-ready sample in <1 day.