Blog

The 5 Cryo-EM Sample Killers: Understanding Why Your Particles Won't Align

Jan 5, 2026

You've spent $150K on a high-resolution cryo-EM microscope session. Your protein is pure, stable, and monodisperse. You make grids, collect data, and begin processing. Then you see it: your 2D class averages are a blurry mess. Particles won't align. Half your classes look like noise.

After three days of data collection, you have nothing usable.

Welcome to the most frustrating bottleneck in cryo-EM: sample preparation. While cryo-EM has revolutionized structural biology, the technique's Achilles' heel remains the grid. Get the sample wrong, and $200K of microscope time produces nothing but expensive noise.

This is Part 1 of our cryo-EM troubleshooting guide. Here, we'll diagnose why samples fail. In Part 2, we'll cover how to fix each problem and optimize your workflow.

Key Takeaways

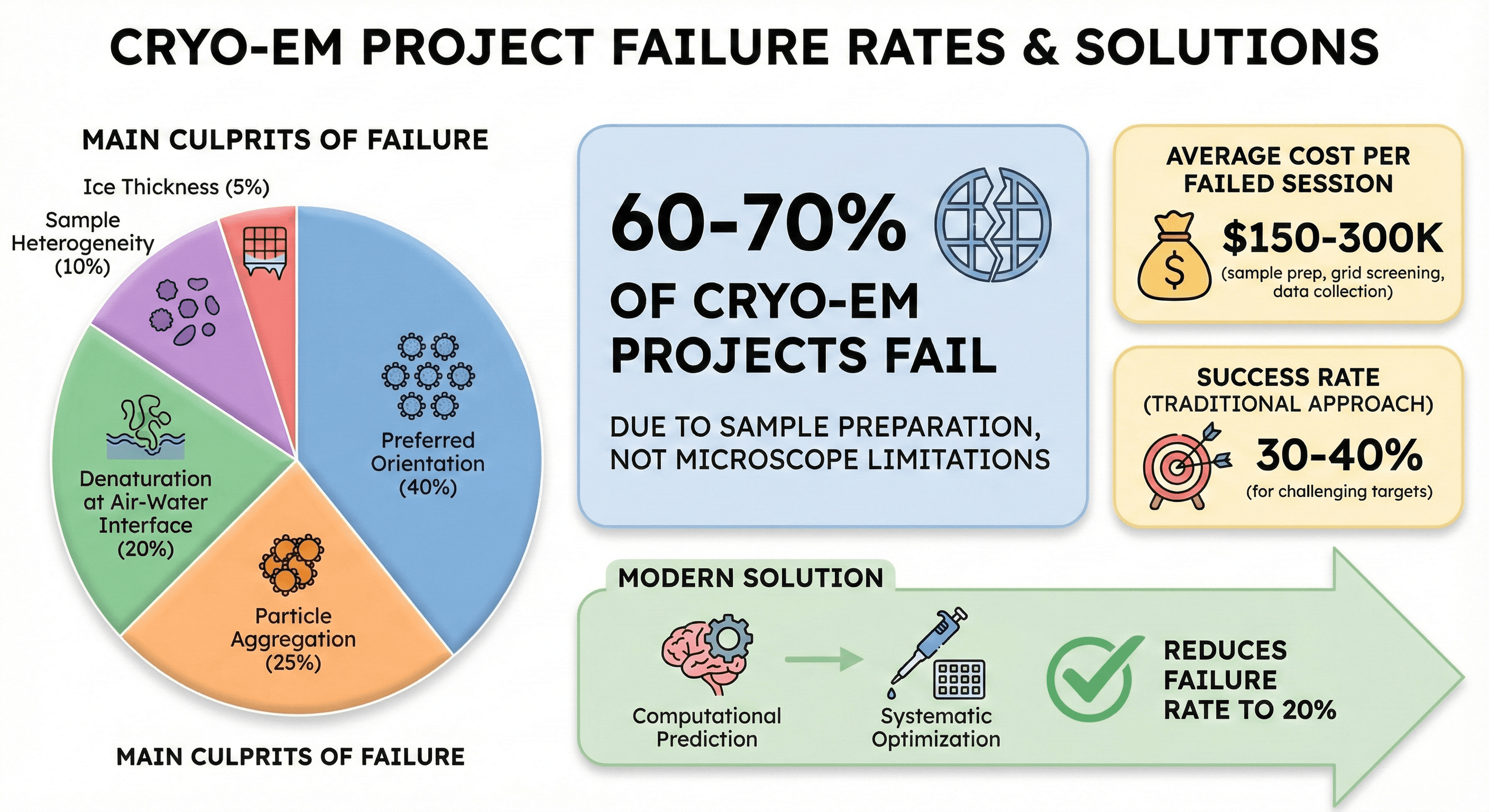

60-70% of cryo-EM projects fail due to sample preparation, not microscope limitations

Main culprits: Preferred orientation (40%), particle aggregation (25%), denaturation at air-water interface (20%), sample heterogeneity (10%), ice thickness (5%)

Average cost per failed session: $150-300K (sample prep, grid screening, data collection)

Success rate: 30-40% for challenging targets with traditional approach

Modern solution: Computational prediction + systematic optimization reduces failure rate to 20%

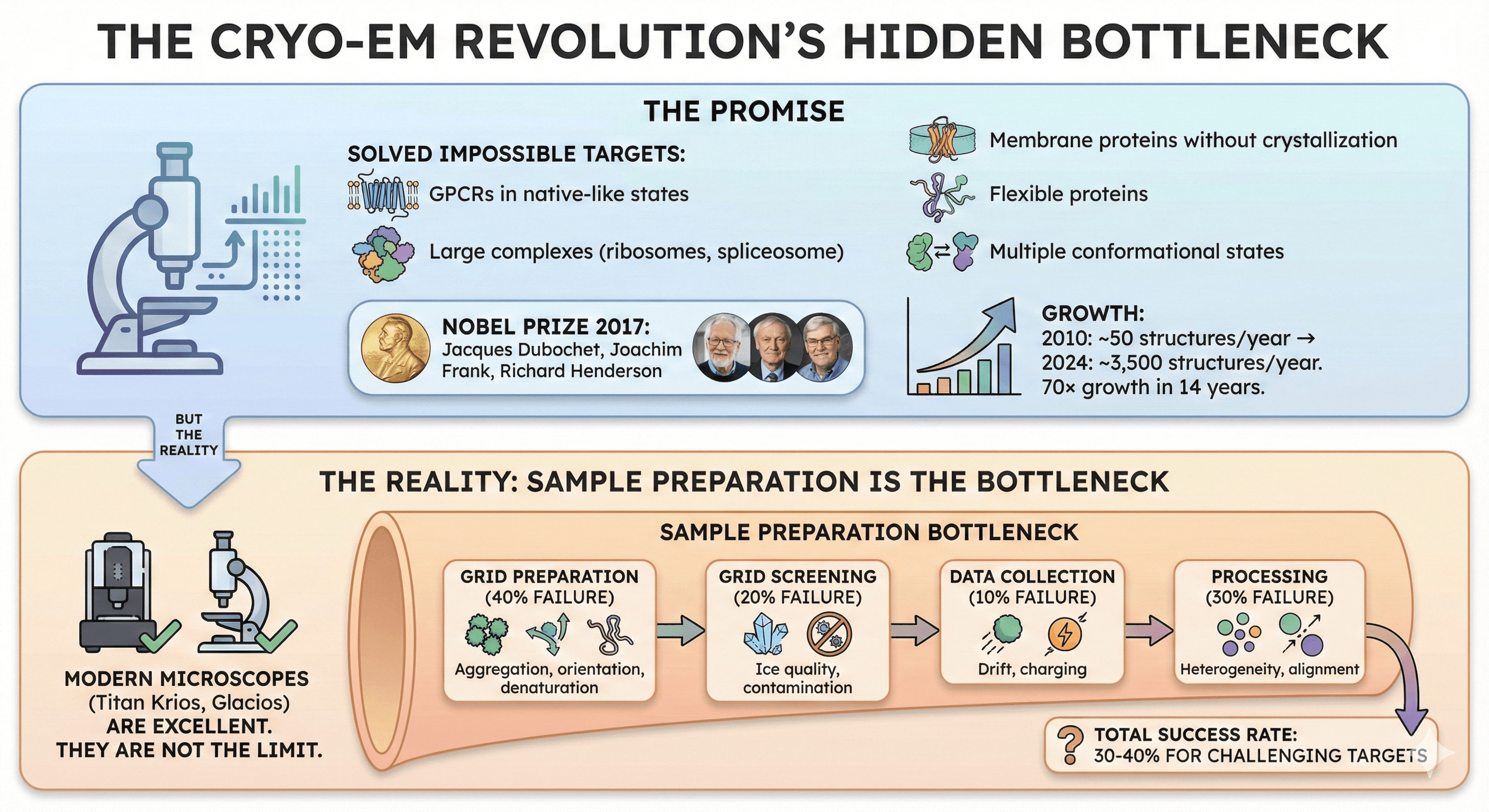

The Cryo-EM Revolution's Hidden Bottleneck

The Promise

Cryo-EM solved the "impossible targets":

GPCRs in native-like states

Large complexes (ribosomes, spliceosome)

Membrane proteins without crystallization

Flexible proteins

Multiple conformational states

Nobel Prize 2017: Jacques Dubochet, Joachim Frank, Richard Henderson

Growth:

2010: ~50 structures/year

2024: ~3,500 structures/year

70× growth in 14 years

The Reality

Cryo-EM success is NOT limited by microscopes. Modern microscopes (Titan Krios, Glacios) are excellent. The bottleneck is sample preparation.

Failure at each stage:

Grid preparation: 40% failure (aggregation, orientation, denaturation)

Grid screening: 20% failure (ice quality, contamination)

Data collection: 10% failure (drift, charging)

Processing: 30% failure (heterogeneity, alignment)

Total success rate: 30-40% for challenging targets

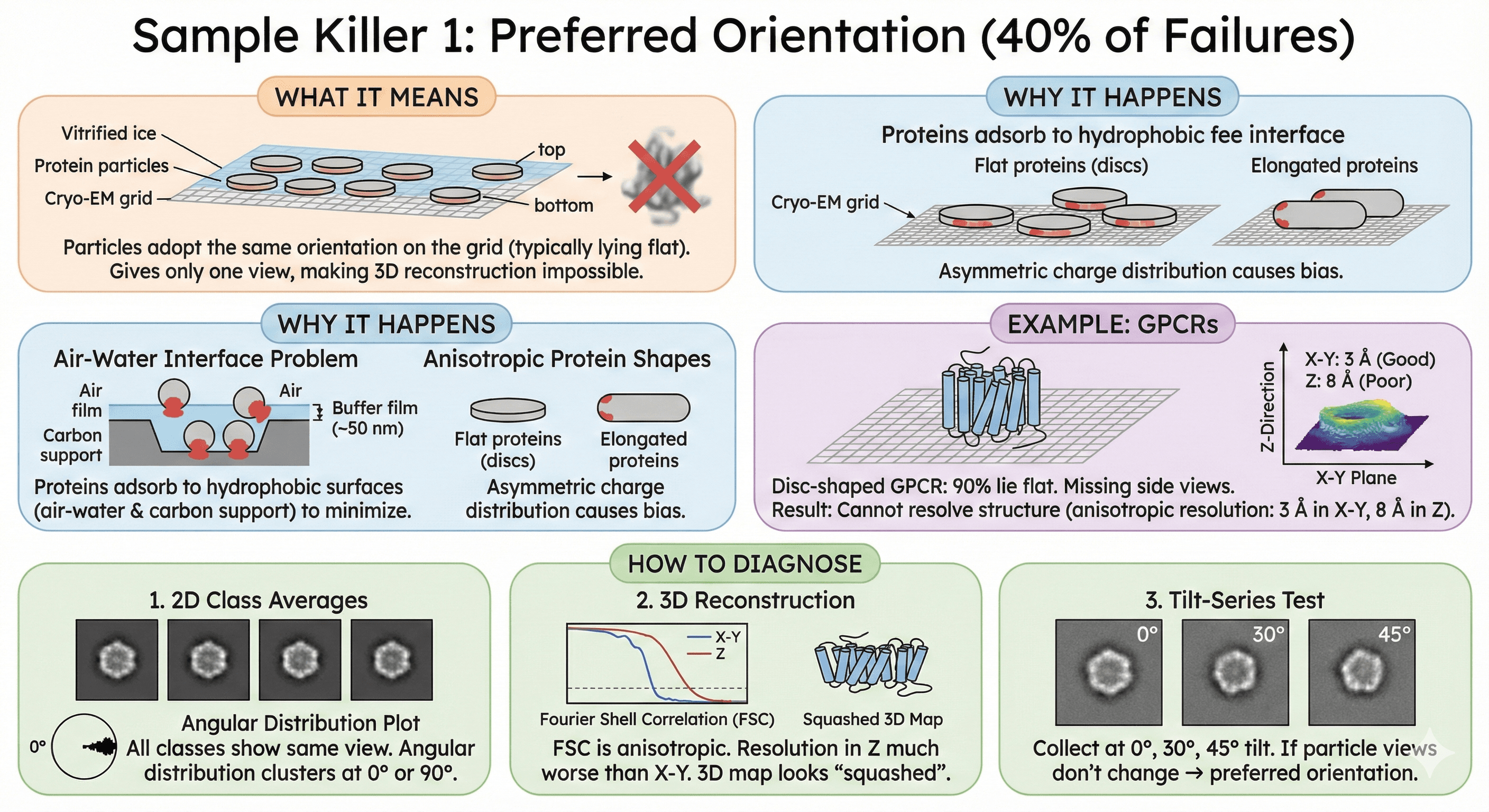

Sample Killer 1: Preferred Orientation (40% of Failures)

What it means: Particles adopt the same orientation on the grid—typically lying flat. This gives you only one view, making 3D reconstruction impossible.

Why It Happens

The air-water interface problem:

When you blot the grid, a thin film of buffer (~50 nm) remains

Creates two hydrophobic surfaces: air-water (top) and carbon support (bottom)

Proteins adsorb to minimize free energy

Result: Proteins orient with most hydrophobic face toward surface

Anisotropic protein shapes:

Flat proteins (discs) lie flat

Elongated proteins align parallel

Asymmetric charge distribution causes bias

Example: GPCRs

Disc-shaped (7-TM cylinder)

90% lie flat on grid

Missing: Side views

Result: Cannot resolve structure (anisotropic resolution: 3 Å in X-Y, 8 Å in Z)

How to Diagnose

1. 2D class averages:

All classes show same view (e.g., all top-down)

No side views, no tilted views

Angular distribution plot clusters at 0° or 90°

2. 3D reconstruction:

Fourier Shell Correlation (FSC) is anisotropic

Resolution in Z-direction much worse than X-Y

3D map looks "squashed"

3. Tilt-series test:

Collect at 0°, 30°, 45° tilt

If particle views don't change → preferred orientation

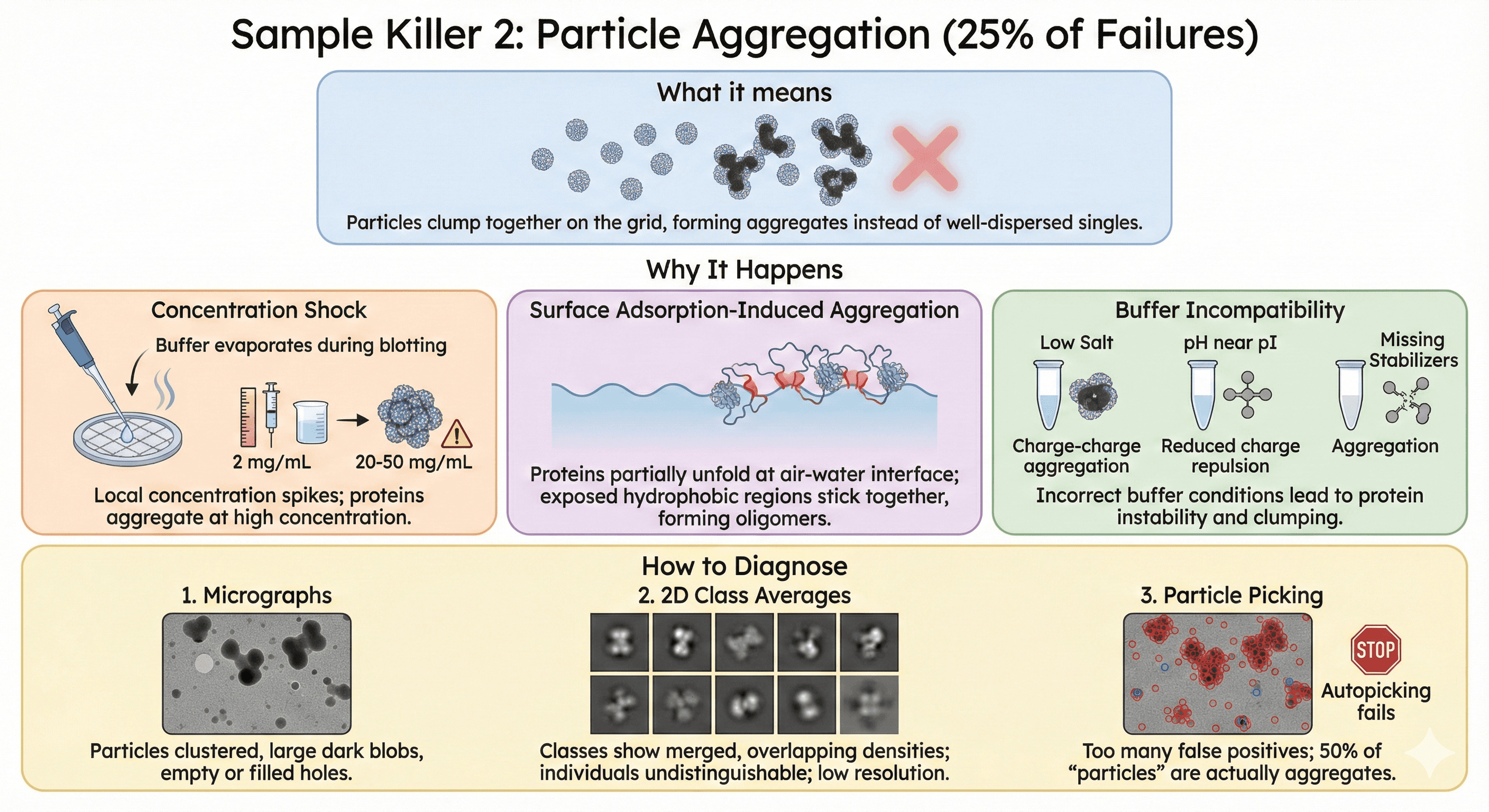

Sample Killer 2: Particle Aggregation (25% of Failures)

What it means: Particles clump together on the grid, forming aggregates instead of well-dispersed singles.

Why It Happens

Concentration shock:

During blotting, buffer evaporates

Local concentration spikes from 2 mg/mL → 20-50 mg/mL

At high concentration, proteins aggregate

Surface adsorption-induced aggregation:

Proteins partially unfold at air-water interface

Exposed hydrophobic regions stick together

Forms oligomers and larger aggregates

Buffer incompatibility:

Low salt → charge-charge aggregation

pH near pI → reduced charge repulsion

Missing stabilizers → aggregation

How to Diagnose

1. Micrographs:

Particles clustered (not evenly distributed)

Large dark blobs instead of individual particles

Holes either empty or completely filled

2. 2D class averages:

Classes show merged particles (overlapping densities)

Cannot distinguish individuals

Low-resolution classes

3. Particle picking:

Autopicking fails (too many false positives)

50% of "particles" are actually aggregates

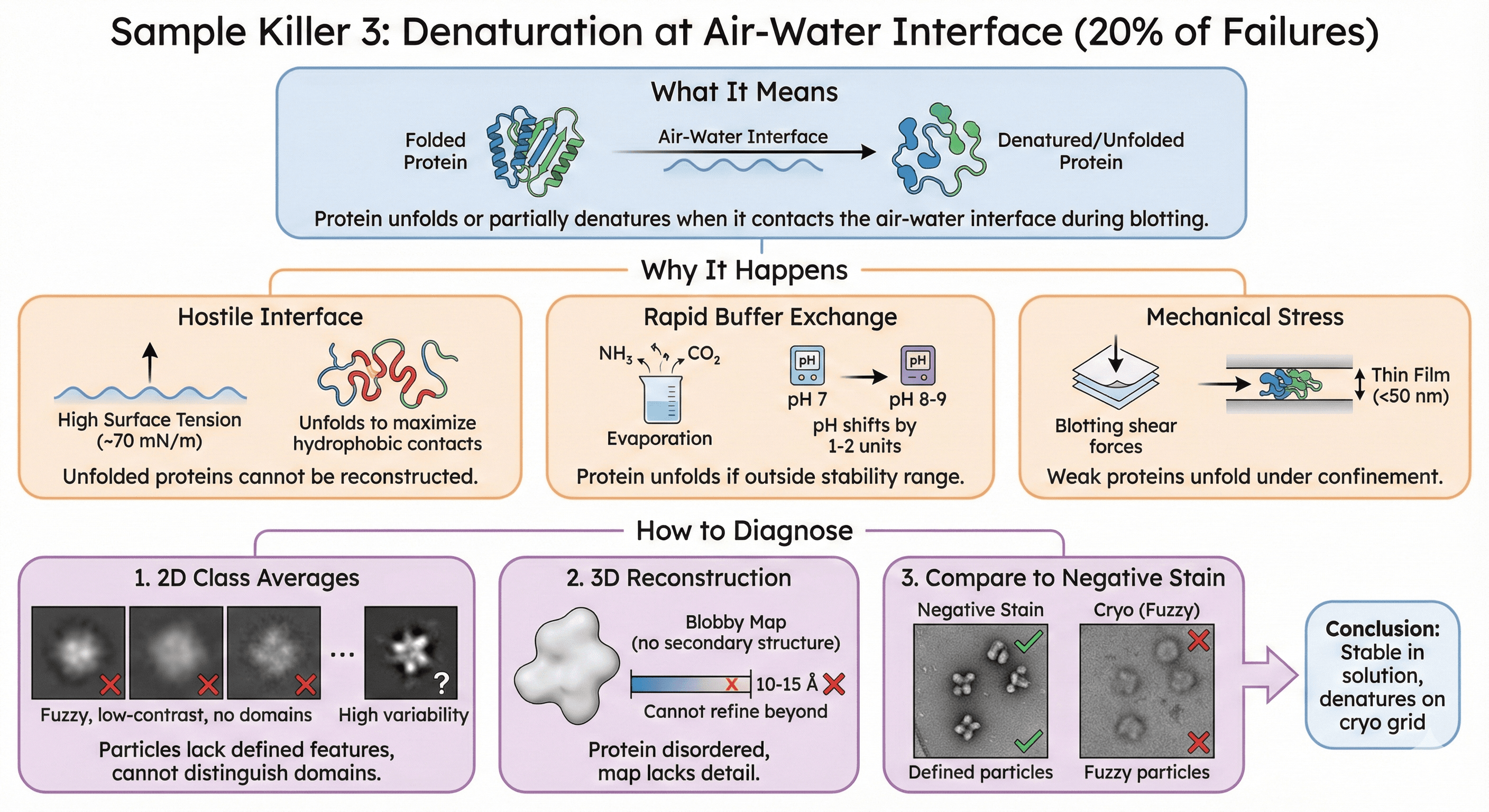

Sample Killer 3: Denaturation at Air-Water Interface (20% of Failures)

What it means: Protein unfolds or partially denatures when it contacts the air-water interface during blotting.

Why It Happens

Hostile interface:

Air-water interface has high surface tension (~70 mN/m)

Proteins unfold to maximize hydrophobic contacts with air

Unfolded proteins cannot be reconstructed

Rapid buffer exchange:

Volatile buffer components evaporate (ammonia, CO₂)

pH shifts by 1-2 units in seconds

Protein unfolds if outside stability range

Mechanical stress:

Blotting applies shear forces

Thin film (<50 nm) confines proteins

Weak proteins unfold

How to Diagnose

1. 2D class averages:

Particles lack defined features (fuzzy, low-contrast)

Cannot distinguish domains

High variability between classes

2. 3D reconstruction:

Cannot refine beyond 10-15 Å (protein disordered)

Map is blobby (no secondary structure)

3. Compare to negative stain:

Negative stain shows defined particles

Cryo shows fuzzy particles

Conclusion: Stable in solution, denatures on cryo grid

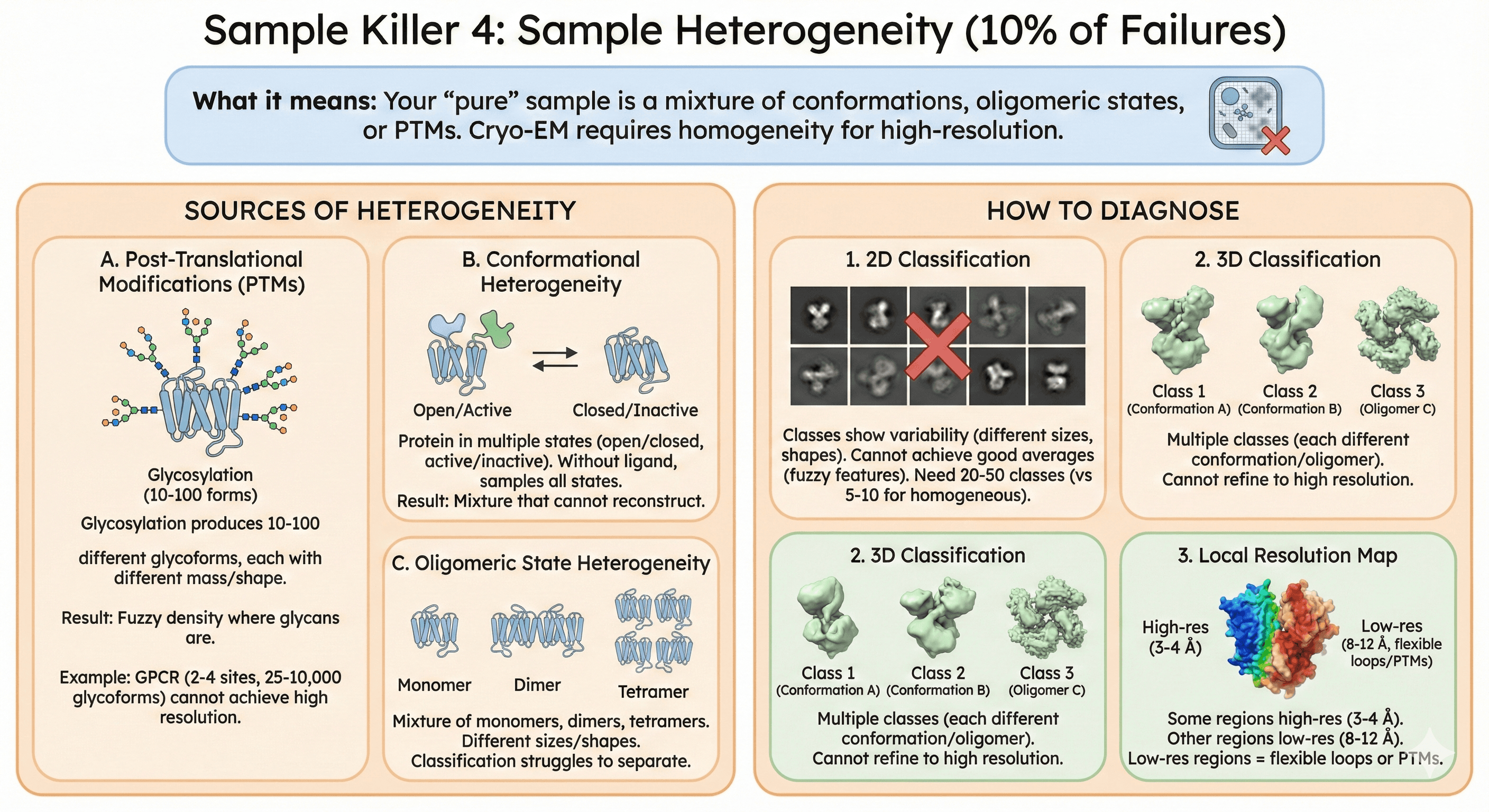

Sample Killer 4: Sample Heterogeneity (10% of Failures)

What it means: Your "pure" sample is a mixture of conformations, oligomeric states, or PTMs. Cryo-EM requires homogeneity for high-resolution.

Sources of Heterogeneity

A. Post-Translational Modifications (PTMs)

The problem:

Glycosylation produces 10-100 different glycoforms

Each has different mass/shape

Result: Fuzzy density where glycans are

Example: GPCR glycosylation

2-4 N-glycosylation sites

Each site: 5-10 glycan structures

Total: 25 to 10,000 glycoforms

Cannot achieve high resolution with this heterogeneity

B. Conformational heterogeneity

Protein in multiple states (open/closed, active/inactive)

Without ligand, samples all states

Result: Mixture that cannot reconstruct

C. Oligomeric state heterogeneity

Mixture of monomers, dimers, tetramers

Different sizes/shapes

Classification struggles to separate

How to Diagnose

1. 2D classification:

Classes show variability (different sizes, shapes)

Cannot achieve good averages (fuzzy features)

Need 20-50 classes (vs 5-10 for homogeneous)

2. 3D classification:

Multiple classes (each different conformation/oligomer)

Cannot refine to high resolution

3. Local resolution map:

Some regions high-res (3-4 Å)

Other regions low-res (8-12 Å)

Low-res regions = flexible loops or PTMs

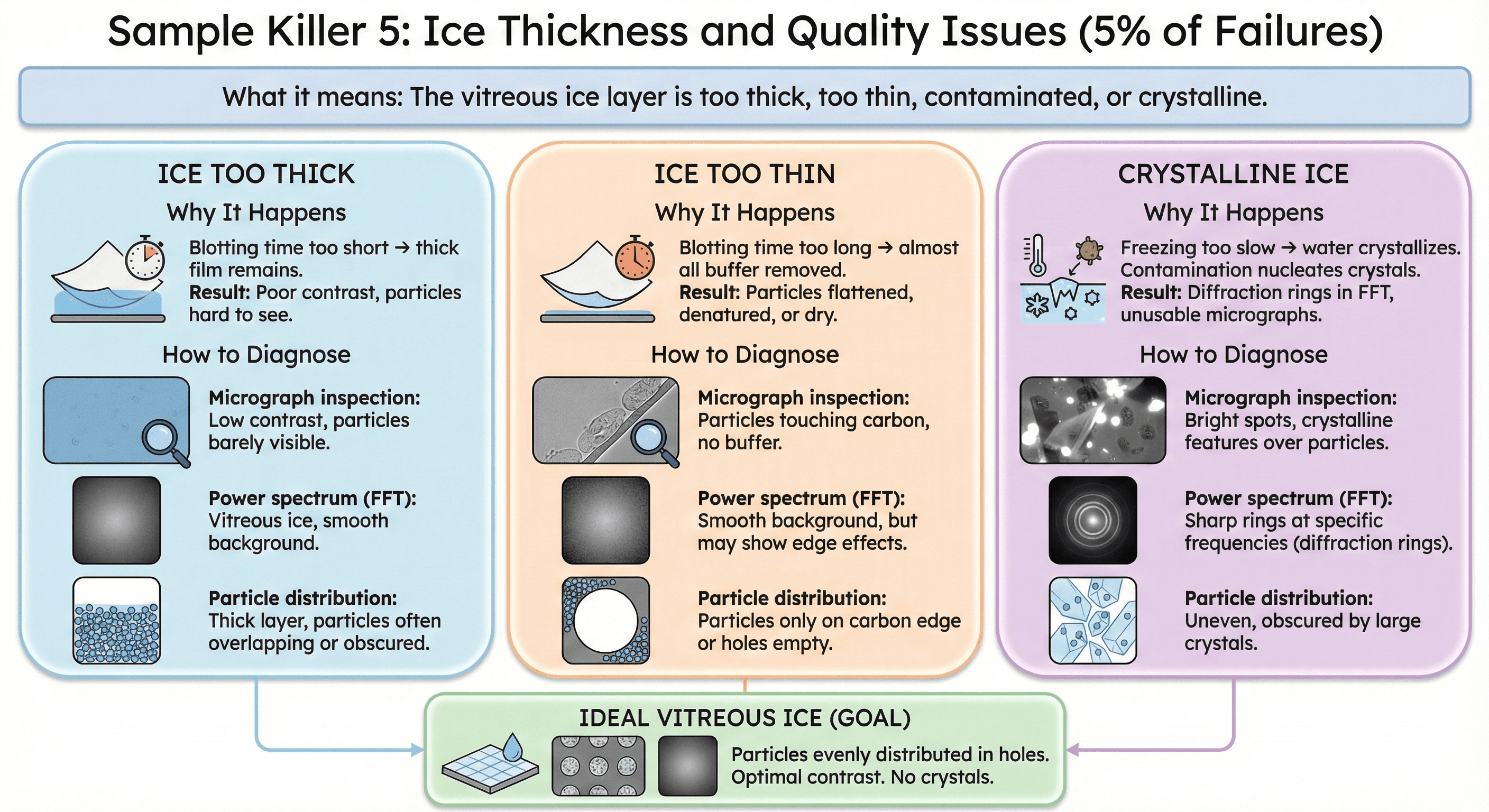

Sample Killer 5: Ice Thickness and Quality Issues (5% of Failures)

What it means: The vitreous ice layer is too thick, too thin, contaminated, or crystalline.

Why It Happens

Ice too thick:

Blotting time too short → thick film remains

Result: Poor contrast, particles hard to see

Ice too thin:

Blotting time too long → almost all buffer removed

Result: Particles flattened, denatured, or dry

Crystalline ice:

Freezing too slow → water crystallizes

Contamination nucleates crystals

Result: Diffraction rings in FFT, unusable micrographs

How to Diagnose

1. Micrograph inspection:

Ice too thick: Low contrast, particles barely visible

Ice too thin: Particles touching carbon, no buffer

Crystalline: Bright spots in FFT, diffraction rings

2. Power spectrum (FFT):

Vitreous ice: Smooth, featureless background

Crystalline ice: Sharp rings at specific frequencies

3. Particle distribution:

Good ice: Particles evenly distributed in holes

Bad ice: Particles only on carbon edge or holes empty

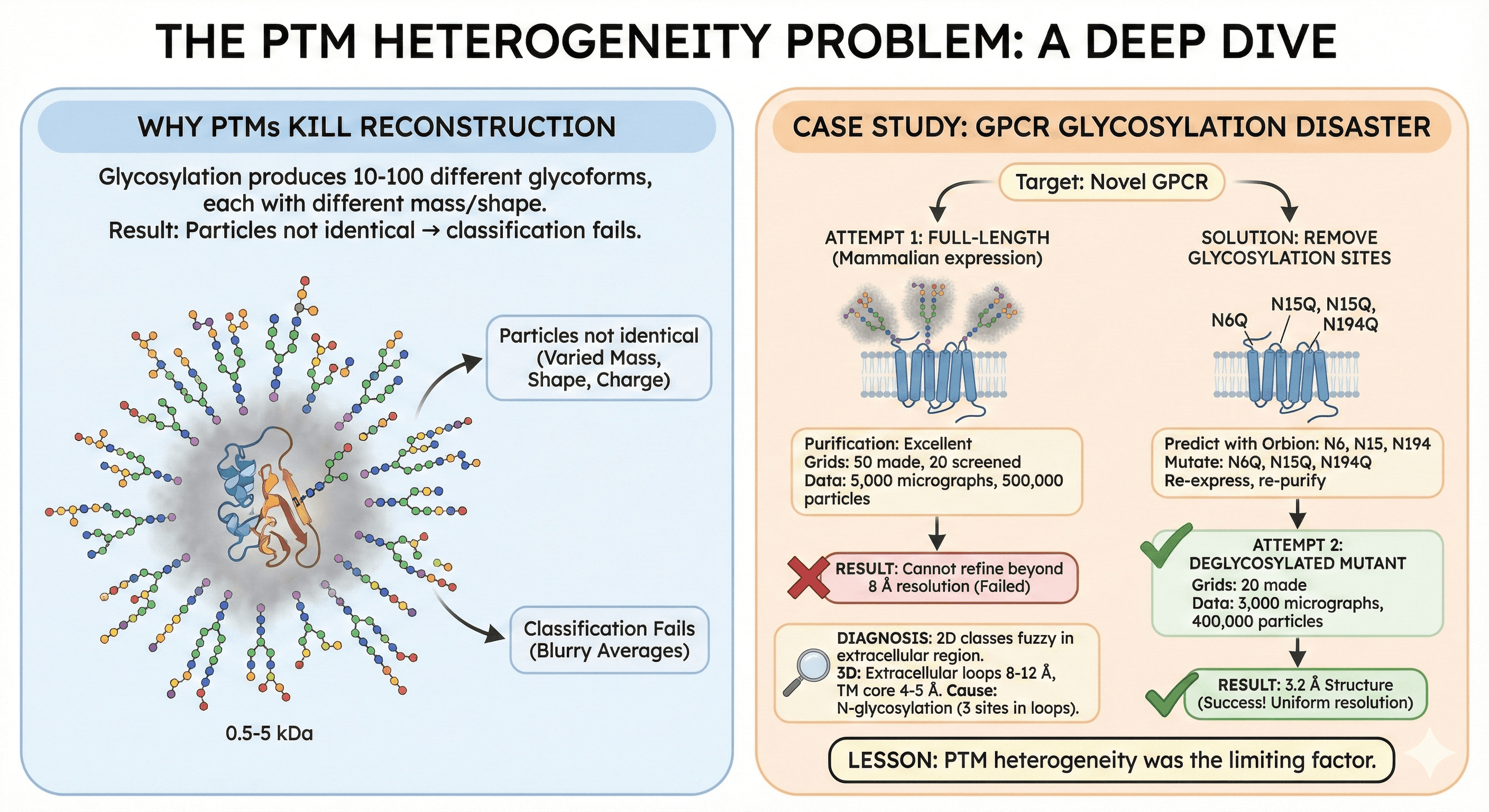

The PTM Heterogeneity Problem: A Deep Dive

This is where most projects underestimate the challenge.

Why PTMs Kill Reconstruction

Glycosylation:

Single site can produce 10-50 glycoforms

Each has different mass (0.5-5 kDa)

Each has different shape and charge

Result: Particles not identical → classification fails

Case Study: GPCR Glycosylation Disaster

Target: Novel GPCR

Attempt 1: Full-length (mammalian expression)

Purification: Excellent

Grids: 50 made, 20 screened

Data: 5,000 micrographs, 500,000 particles

Result: Cannot refine beyond 8 Å resolution

Diagnosis:

2D classes fuzzy in extracellular region

3D: Extracellular loops 8-12 Å, TM core 4-5 Å

Cause: N-glycosylation (3 sites in loops)

Solution: Remove glycosylation sites

Predict with Orbion: N6, N15, N194

Mutate: N6Q, N15Q, N194Q

Re-express, re-purify

Attempt 2: Deglycosylated mutant

Grids: 20 made

Data: 3,000 micrographs, 400,000 particles

Result: 3.2 Å structure (uniform resolution)

Lesson: PTM heterogeneity was the limiting factor.

Understanding Your Problem: Quick Diagnostic

Symptom | Likely Problem | Quick Test |

|---|---|---|

All 2D classes show same view | Preferred orientation | Check angular distribution |

Particles clustered in micrographs | Aggregation | DLS at crystallization concentration |

2D classes fuzzy, no features | Denaturation | Compare to negative stain |

Many 3D classes needed | Heterogeneity | Check for PTMs, oligomers |

Bright spots in FFT | Crystalline ice | Check blotting parameters |

Very dark or very light holes | Ice thickness | Optimize blot time |

Key Takeaway

Cryo-EM sample preparation isn't random trial-and-error. It's a predictable engineering problem with known failure modes:

Preferred orientation (40%): Particles lie flat

Aggregation (25%): Clumping at high concentration

Denaturation (20%): Unfolding at air-water interface

Heterogeneity (10%): PTMs, conformational states

Ice quality (5%): Too thick, thin, or crystalline

Understanding your failure mode is the first step to solving it.