Blog

Membrane Protein Purification: Detergent Screening Guide

Dec 19, 2025

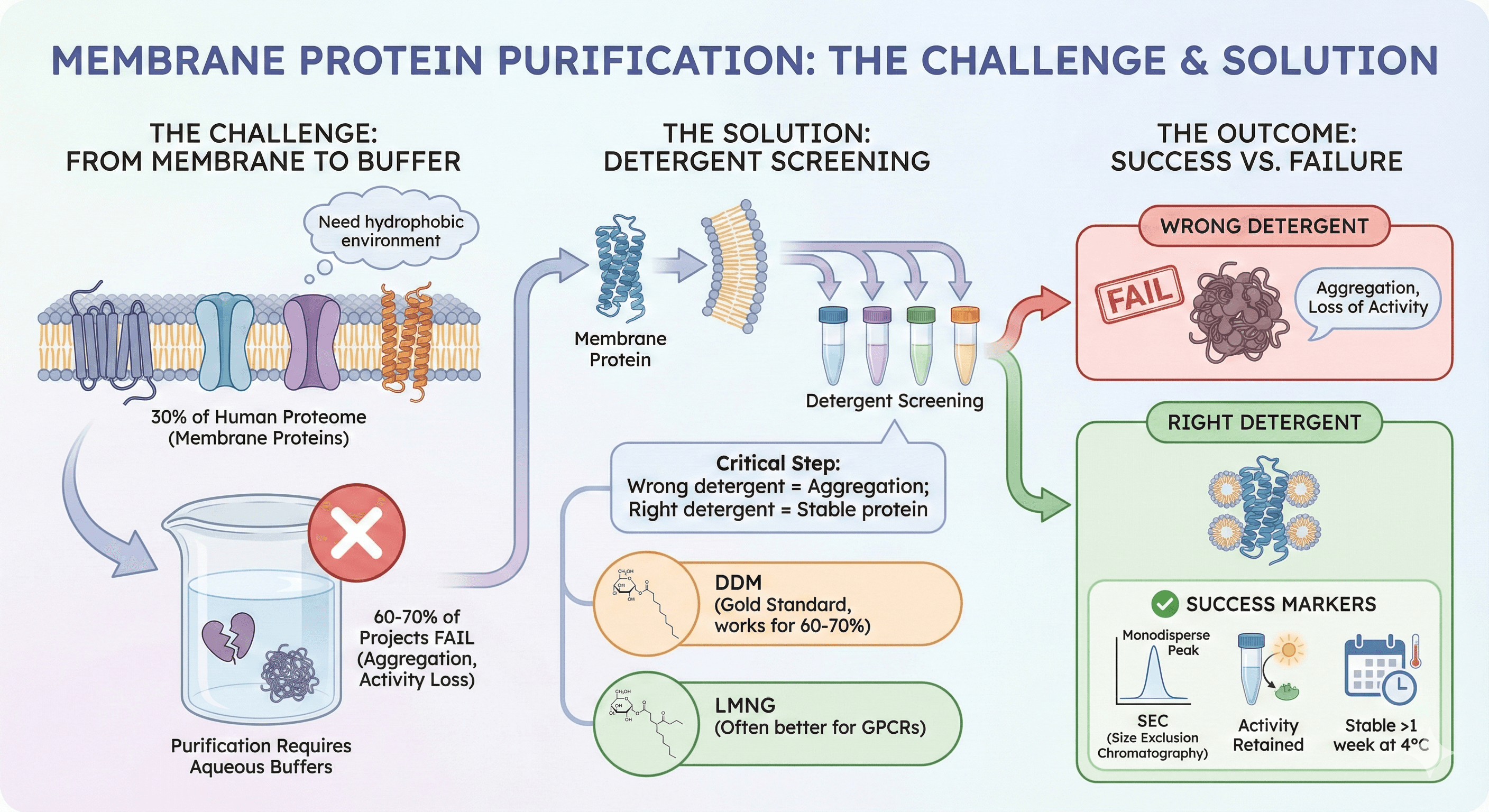

You've spent six months optimizing expression. Finally, your Western blot shows your GPCR is in the membrane fraction—success! Now you just need to purify it. You add detergent, solubilize the membranes, run it through Ni-NTA, and... it's gone. Either it didn't bind, it aggregated during elution, or it eluted as a heterogeneous smear.

Welcome to membrane protein purification—the point where 60-70% of membrane protein projects fail. The protein is made, it's in the membrane, but you cannot get it out in a functional, stable form. Here's why membrane proteins are uniquely challenging, and how to actually solubilize and purify them.

Key Takeaways

30% of the human proteome is membrane proteins (GPCRs, ion channels, transporters)

60-70% of membrane protein projects fail during purification (aggregation, loss of activity)

The challenge: Membrane proteins need hydrophobic environment (lipid bilayer), but purification requires aqueous buffers

Detergent screening is critical: Wrong detergent = aggregation; right detergent = stable protein

DDM is gold standard (works for 60-70% of proteins), but LMNG often better for GPCRs

Success markers: SEC shows monodisperse peak, activity retained, stable >1 week at 4°C

Why Membrane Proteins Are Hard to Purify

The Fundamental Problem: Hydrophobic Surface

Soluble proteins:

Hydrophobic residues buried in core

Hydrophilic residues on surface (interact with water)

Stable in aqueous buffer

Membrane proteins:

Hydrophobic residues on surface (transmembrane helices interact with lipid tails)

Hydrophilic residues at loops (extracellular/intracellular)

Cannot exist stably in aqueous buffer (exposed hydrophobic surface drives aggregation)

The dilemma:

In membrane: Protein is stable, functional, but cannot purify (embedded in lipid bilayer)

In aqueous buffer: Can purify, but protein aggregates (exposed hydrophobic surface)

Solution: Introduce amphipathic molecules (detergents, nanodiscs, amphipols) that:

Shield hydrophobic transmembrane regions

Provide solubility in aqueous buffer

Maintain protein stability and function

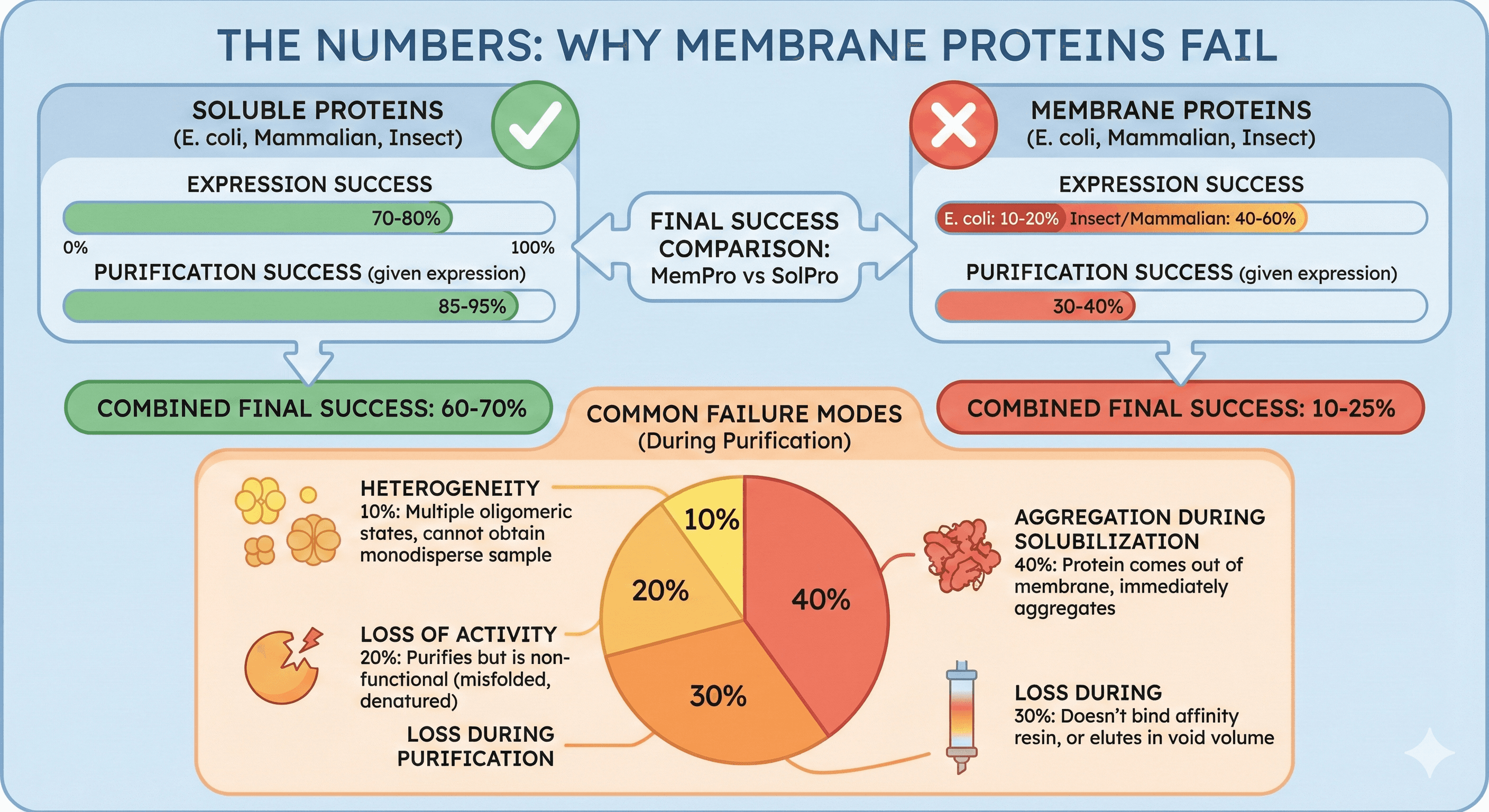

The Numbers: Why Membrane Proteins Fail

Expression success rate:

Soluble proteins (E. coli): 70-80%

Membrane proteins (E. coli): 10-20%

Membrane proteins (insect/mammalian): 40-60%

Purification success rate (given successful expression):

Soluble proteins: 85-95%

Membrane proteins: 30-40%

Combined (expression + purification):

Soluble proteins: 60-70% final success

Membrane proteins: 10-25% final success

Common failure modes:

Aggregation during solubilization (40%): Protein comes out of membrane, immediately aggregates

Loss during purification (30%): Doesn't bind affinity resin, or elutes in void volume

Loss of activity (20%): Purifies but is non-functional (misfolded, denatured)

Heterogeneity (10%): Multiple oligomeric states, cannot obtain monodisperse sample

Membrane Protein Classes

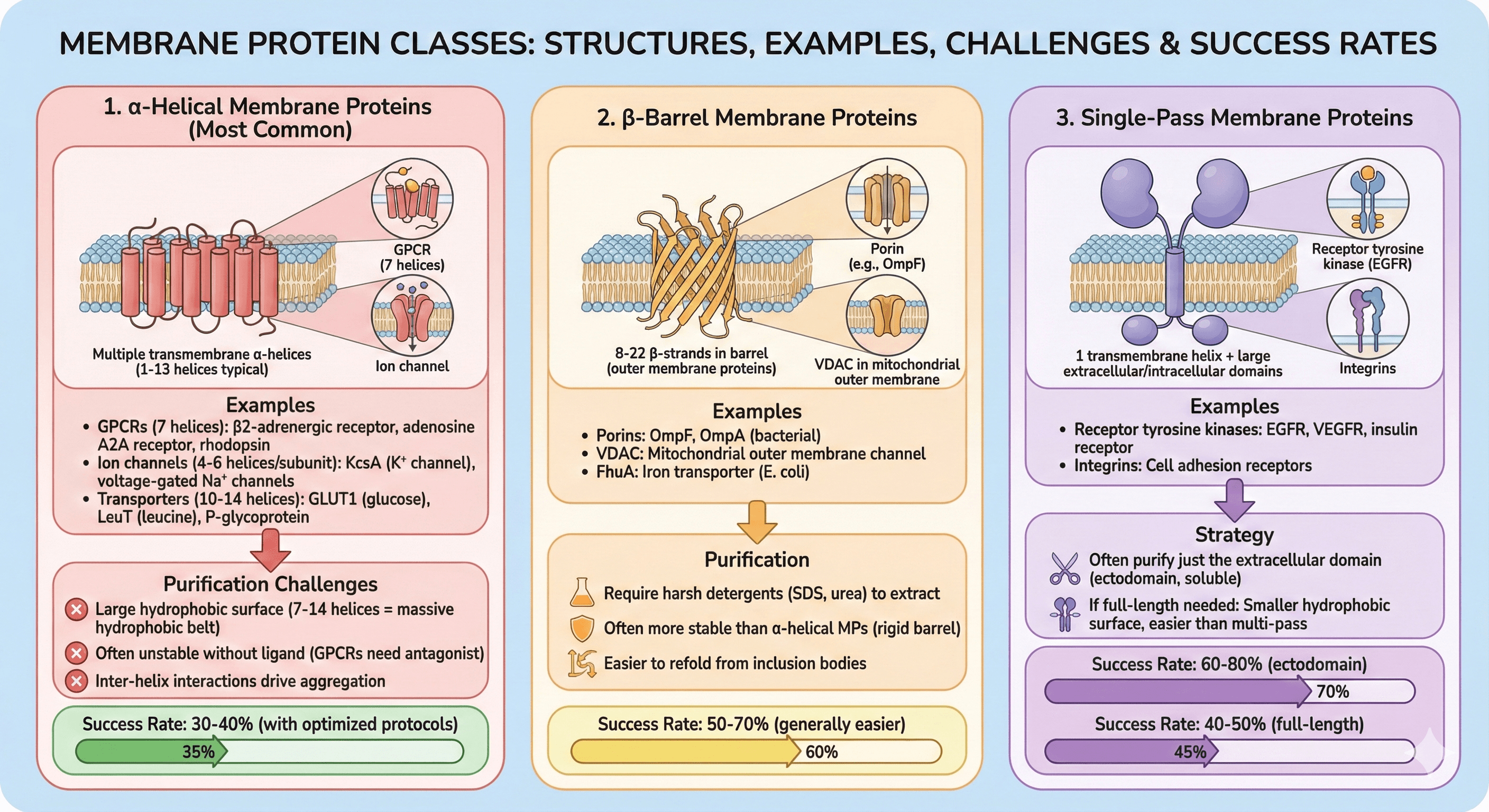

1. α-Helical Membrane Proteins (Most Common)

Structure: Multiple transmembrane α-helices (1-13 helices typical)

Examples:

GPCRs (7 helices): β2-adrenergic receptor, adenosine A2A receptor, rhodopsin

Ion channels (4-6 helices per subunit): KcsA (K⁺ channel), voltage-gated Na⁺ channels

Transporters (10-14 helices): GLUT1 (glucose), LeuT (leucine), P-glycoprotein

Purification challenges:

Large hydrophobic surface (7-14 helices = massive hydrophobic belt)

Often unstable without ligand (GPCRs need antagonist)

Inter-helix interactions drive aggregation

Success rate: 30-40% (with optimized protocols)

2. β-Barrel Membrane Proteins

Structure: 8-22 β-strands in barrel (outer membrane proteins)

Examples:

Porins: OmpF, OmpA (bacterial)

VDAC: Mitochondrial outer membrane channel

FhuA: Iron transporter (E. coli)

Purification:

Require harsh detergents (SDS, urea) to extract

Often more stable than α-helical MPs (rigid barrel)

Easier to refold from inclusion bodies

Success rate: 50-70% (generally easier)

3. Single-Pass Membrane Proteins

Structure: 1 transmembrane helix + large extracellular/intracellular domains

Examples:

Receptor tyrosine kinases: EGFR, VEGFR, insulin receptor

Integrins: Cell adhesion receptors

Strategy:

Often purify just the extracellular domain (ectodomain, soluble)

If full-length needed: Smaller hydrophobic surface, easier than multi-pass

Success rate: 60-80% (ectodomain), 40-50% (full-length)

The Purification Workflow: Stage-by-Stage

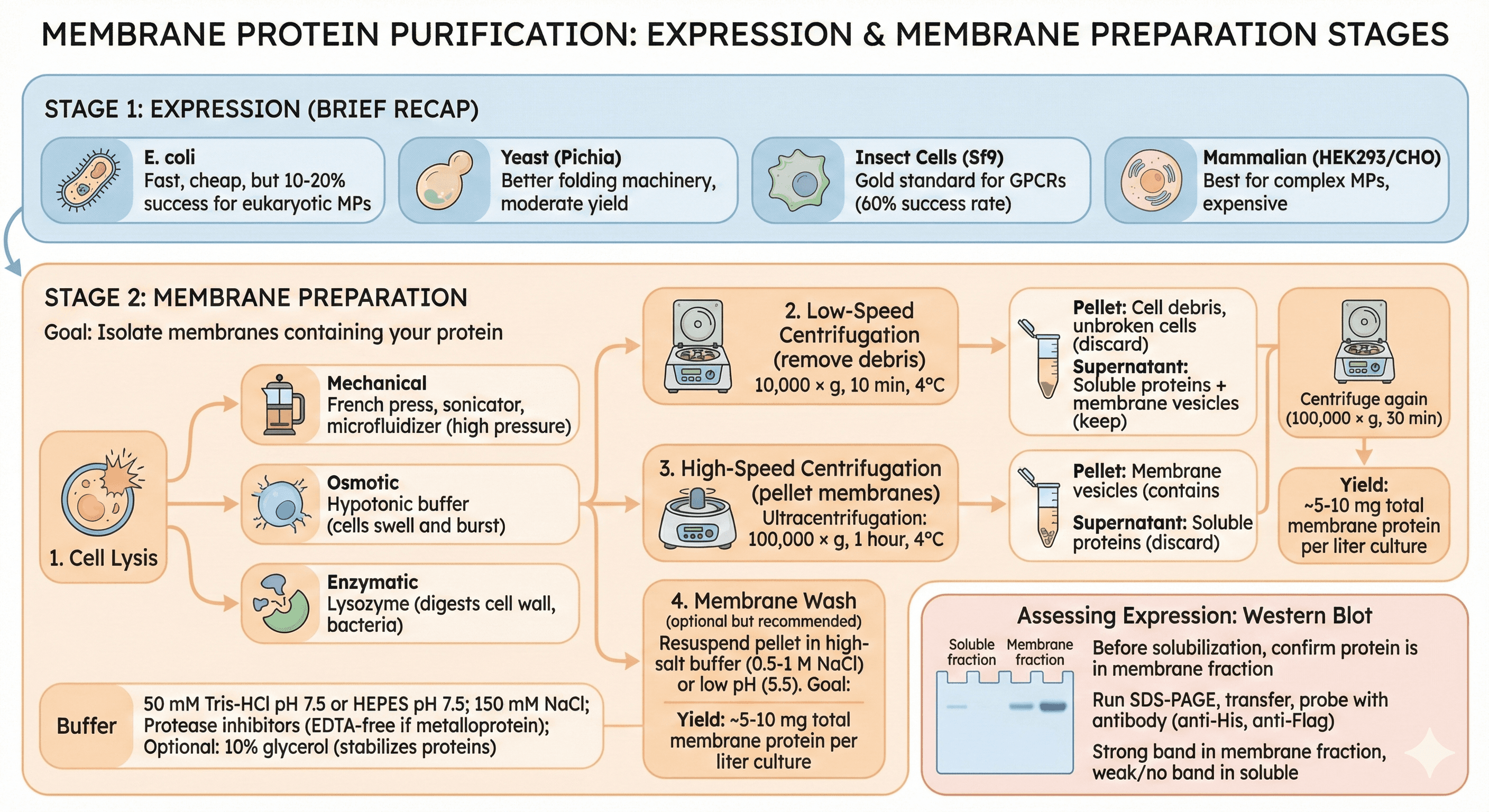

Stage 1: Expression (Brief Recap)

Expression system selection:

E. coli: Fast, cheap, but 10-20% success for eukaryotic MPs

Yeast (Pichia): Better folding machinery, moderate yield

Insect cells (Sf9): Gold standard for GPCRs (60% success rate)

Mammalian (HEK293/CHO): Best for complex MPs, expensive

Stage 2: Membrane Preparation

Goal: Isolate membranes containing your protein

Protocol:

1. Cell Lysis

Mechanical: French press, sonicator, microfluidizer (high pressure)

Osmotic: Hypotonic buffer (cells swell and burst)

Enzymatic: Lysozyme (digests cell wall, bacteria)

Buffer:

50 mM Tris-HCl pH 7.5 or HEPES pH 7.5

150 mM NaCl

Protease inhibitors (EDTA-free if metalloprotein)

Optional: 10% glycerol (stabilizes proteins)

2. Low-Speed Centrifugation (remove debris)

10,000 × g, 10 min, 4°C

Pellet: Cell debris, unbroken cells (discard)

Supernatant: Soluble proteins + membrane vesicles (keep)

3. High-Speed Centrifugation (pellet membranes)

Ultracentrifugation: 100,000 × g, 1 hour, 4°C

Pellet: Membrane vesicles (contains your MP)

Supernatant: Soluble proteins (discard)

4. Membrane Wash (optional but recommended)

Resuspend pellet in high-salt buffer (0.5-1 M NaCl) or low pH (5.5)

Goal: Remove peripherally associated proteins

Centrifuge again (100,000 × g, 30 min)

Yield: ~5-10 mg total membrane protein per liter culture

Assessing Expression: Western Blot

Before solubilization, confirm protein is in membrane fraction

Sample: Soluble fraction + membrane fraction

Run SDS-PAGE, transfer, probe with antibody (anti-His, anti-Flag)

Expected: Strong band in membrane fraction, weak/no band in soluble

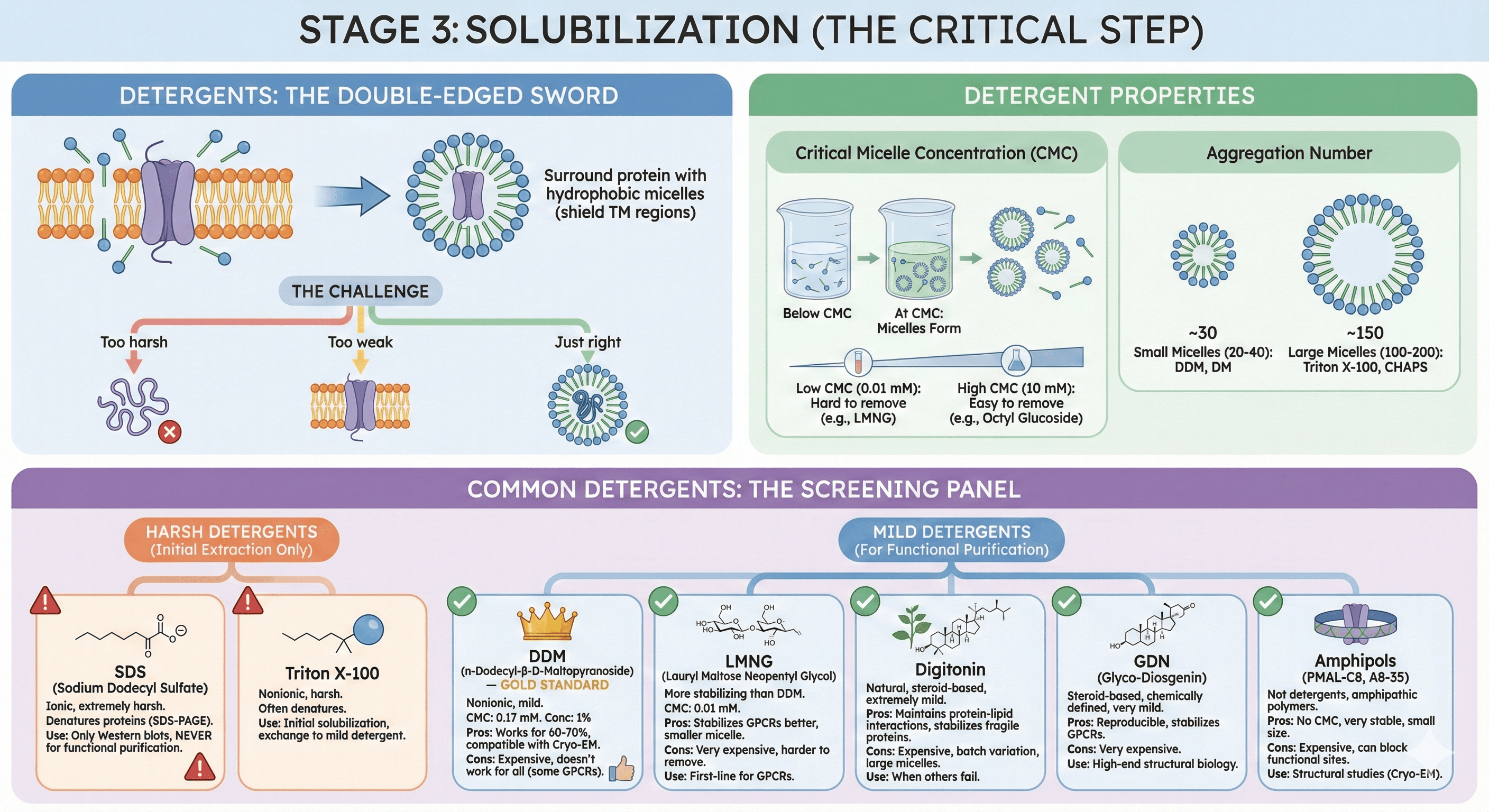

Stage 3: Solubilization (The Critical Step)

Detergents: The Double-Edged Sword

What detergents do:

Disrupt lipid bilayer (insert into membrane)

Surround protein with hydrophobic micelles (shield TM regions)

Allow protein to exist in aqueous solution

The challenge:

Too harsh: Protein denatures (unfolds, loses structure)

Too weak: Protein doesn't solubilize (stays in membrane)

Just right: Protein solubilizes, stays folded and functional

Detergent Properties

Critical Micelle Concentration (CMC):

Concentration at which detergent forms micelles

Low CMC (0.01 mM): Hard to remove (stays bound), e.g., LMNG

High CMC (10 mM): Easy to remove (dialyzes out), e.g., octyl glucoside

Aggregation number:

Number of detergent molecules per micelle

Small micelles (20-40): DDM, DM

Large micelles (100-200): Triton X-100, CHAPS

Common Detergents: The Screening Panel

Harsh Detergents (Initial Extraction Only)

1. SDS (Sodium Dodecyl Sulfate)

Ionic, extremely harsh

Denatures proteins (used in SDS-PAGE)

Use: Only for Western blots, never for functional purification

2. Triton X-100

Nonionic, harsh

Often denatures membrane proteins

Use: Sometimes for initial solubilization, but exchange to milder detergent

Mild Detergents (For Functional Purification)

3. DDM (n-Dodecyl-β-D-Maltopyranoside) — GOLD STANDARD

Nonionic, mild, stabilizes many MPs

CMC: 0.17 mM (relatively easy to remove)

Concentration: 1% (w/v) for solubilization, 0.02-0.05% for purification

Pros:

Works for 60-70% of membrane proteins

Well-tolerated

Compatible with crystallization, Cryo-EM

Cons:

Doesn't work for all proteins (some GPCRs aggregate)

Expensive (~$100-200/g)

4. LMNG (Lauryl Maltose Neopentyl Glycol)

Maltose-based, modified linker

More stabilizing than DDM (better for challenging targets)

CMC: 0.01 mM (harder to remove)

Pros:

Stabilizes GPCRs better than DDM (β2-AR, A2A receptor)

Smaller micelle size (better for Cryo-EM)

Cons:

More expensive (~5-10× DDM cost)

Harder to remove (low CMC)

Use: First-line for GPCRs

5. Digitonin

Natural product (from Digitalis plants)

Steroid-based, extremely mild

Preserves native lipids around protein

Pros:

Maintains protein-lipid interactions

Stabilizes very fragile proteins (respiratory complexes, some GPCRs)

Cons:

Expensive ($50-100/g)

Heterogeneous (batch variation)

Large micelles (harder to crystallize)

Use: When everything else fails

6. GDN (Glyco-Diosgenin)

Steroid-based, like digitonin but chemically defined

Very mild, homogeneous

Pros:

Reproducible purifications

Stabilizes GPCRs (A2A receptor structure solved in GDN)

Cons:

Very expensive ($300-500/g)

Use: High-end structural biology

7. Amphipols (PMAL-C8, A8-35)

Not detergents, but amphipathic polymers

Wrap around protein like a belt

Pros:

No CMC (don't form micelles)

Very stable (proteins soluble for months)

Small size (better for Cryo-EM resolution)

Cons:

Expensive ($100-200/g)

Can block functional sites

Use: Structural studies (Cryo-EM), detergent-free environment

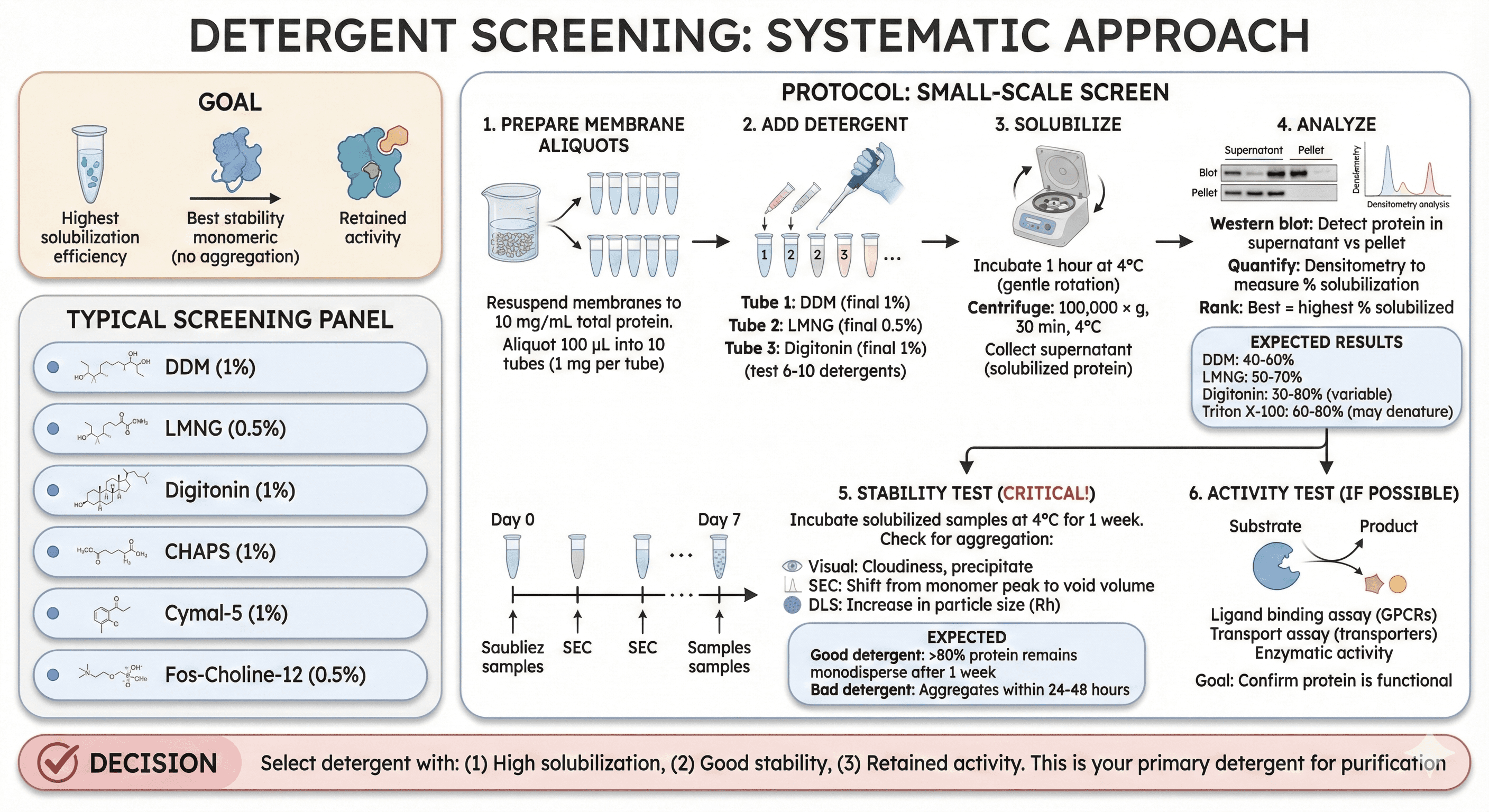

Detergent Screening: Systematic Approach

Goal: Find detergent that gives:

Highest solubilization efficiency

Best stability (no aggregation)

Retained activity

Typical screening panel:

DDM (1%)

LMNG (0.5%)

Digitonin (1%)

CHAPS (1%)

Cymal-5 (1%)

Fos-Choline-12 (0.5%)

Protocol: Small-Scale Screen

1. Prepare Membrane Aliquots

Resuspend membranes to 10 mg/mL total protein

Aliquot 100 μL into 10 tubes (1 mg per tube)

2. Add Detergent

Tube 1: DDM (final 1%)

Tube 2: LMNG (final 0.5%)

Tube 3: Digitonin (final 1%)

... (test 6-10 detergents)

3. Solubilize

Incubate 1 hour at 4°C (gentle rotation)

Centrifuge: 100,000 × g, 30 min, 4°C

Collect supernatant (solubilized protein)

4. Analyze

Western blot: Detect protein in supernatant vs pellet

Quantify: Densitometry to measure % solubilization

Rank: Best = highest % solubilized

Expected results:

DDM: 40-60% solubilization

LMNG: 50-70%

Digitonin: 30-80% (variable)

Triton X-100: 60-80% (but may denature)

5. Stability Test (Critical!)

Incubate solubilized samples at 4°C for 1 week

Check for aggregation:

Visual: Cloudiness, precipitate

SEC: Shift from monomer peak to void volume

DLS: Increase in particle size (Rh)

Expected:

Good detergent: >80% protein remains monodisperse after 1 week

Bad detergent: Aggregates within 24-48 hours

6. Activity Test (If Possible)

Ligand binding assay (GPCRs)

Transport assay (transporters)

Enzymatic activity

Goal: Confirm protein is functional

Decision:

Select detergent with: (1) High solubilization, (2) Good stability, (3) Retained activity

This is your primary detergent for purification

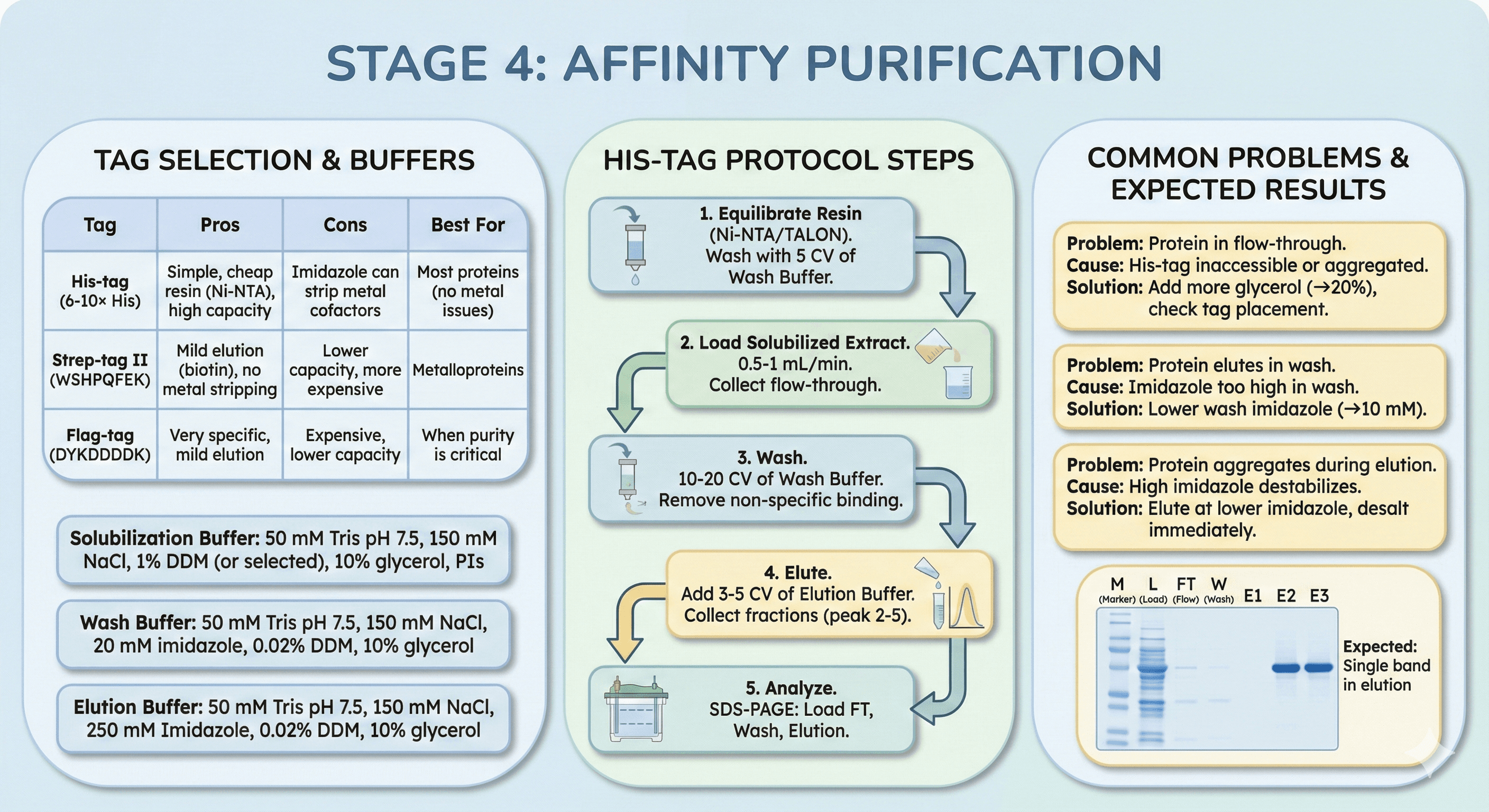

Stage 4: Affinity Purification

Tag Selection

His-tag (6-10× His):

Pros: Simple, cheap resin (Ni-NTA), high capacity

Cons: Imidazole can strip metal cofactors

Best for: Most proteins (no metal cofactor issues)

Strep-tag II (WSHPQFEK):

Pros: Mild elution (biotin), no metal stripping

Cons: Lower capacity, more expensive

Best for: Metalloproteins

Flag-tag (DYKDDDDK):

Pros: Very specific, mild elution

Cons: Expensive, lower capacity

Best for: When purity is critical

Protocol: His-Tag Affinity Purification

Buffers:

Solubilization buffer:

50 mM Tris pH 7.5, 150 mM NaCl

1% DDM (or selected detergent)

10% glycerol, protease inhibitors

Wash buffer:

50 mM Tris pH 7.5, 150 mM NaCl

20 mM imidazole (remove non-specific binding)

0.02% DDM (maintain solubilization, 10× CMC)

10% glycerol

Elution buffer:

50 mM Tris pH 7.5, 150 mM NaCl

250 mM imidazole

0.02% DDM

10% glycerol

Steps:

1. Equilibrate Resin

Ni-NTA or TALON (2-5 mL per L culture)

Wash with 5 CV of wash buffer

2. Load Solubilized Extract

Flow rate: 0.5-1 mL/min (gravity or pump)

Collect flow-through (save for analysis)

3. Wash

10-20 CV of wash buffer

Remove non-specific binding

4. Elute

Add 3-5 CV of elution buffer

Collect fractions (0.5-1 mL each)

Peak fractions: Typically fractions 2-5

5. Analyze

SDS-PAGE: Load flow-through, wash, elution

Expected: Single band at expected MW in elution fractions

Common Problems:

Problem 1: Protein in flow-through (doesn't bind)

Cause: His-tag inaccessible or protein aggregated

Solution: Add more glycerol (10% → 20%), check tag placement

Problem 2: Protein elutes in wash

Cause: Imidazole too high in wash

Solution: Lower wash imidazole (20 mM → 10 mM)

Problem 3: Protein aggregates during elution

Cause: High imidazole destabilizes

Solution: Elute at lower imidazole (150-250 mM), desalt immediately

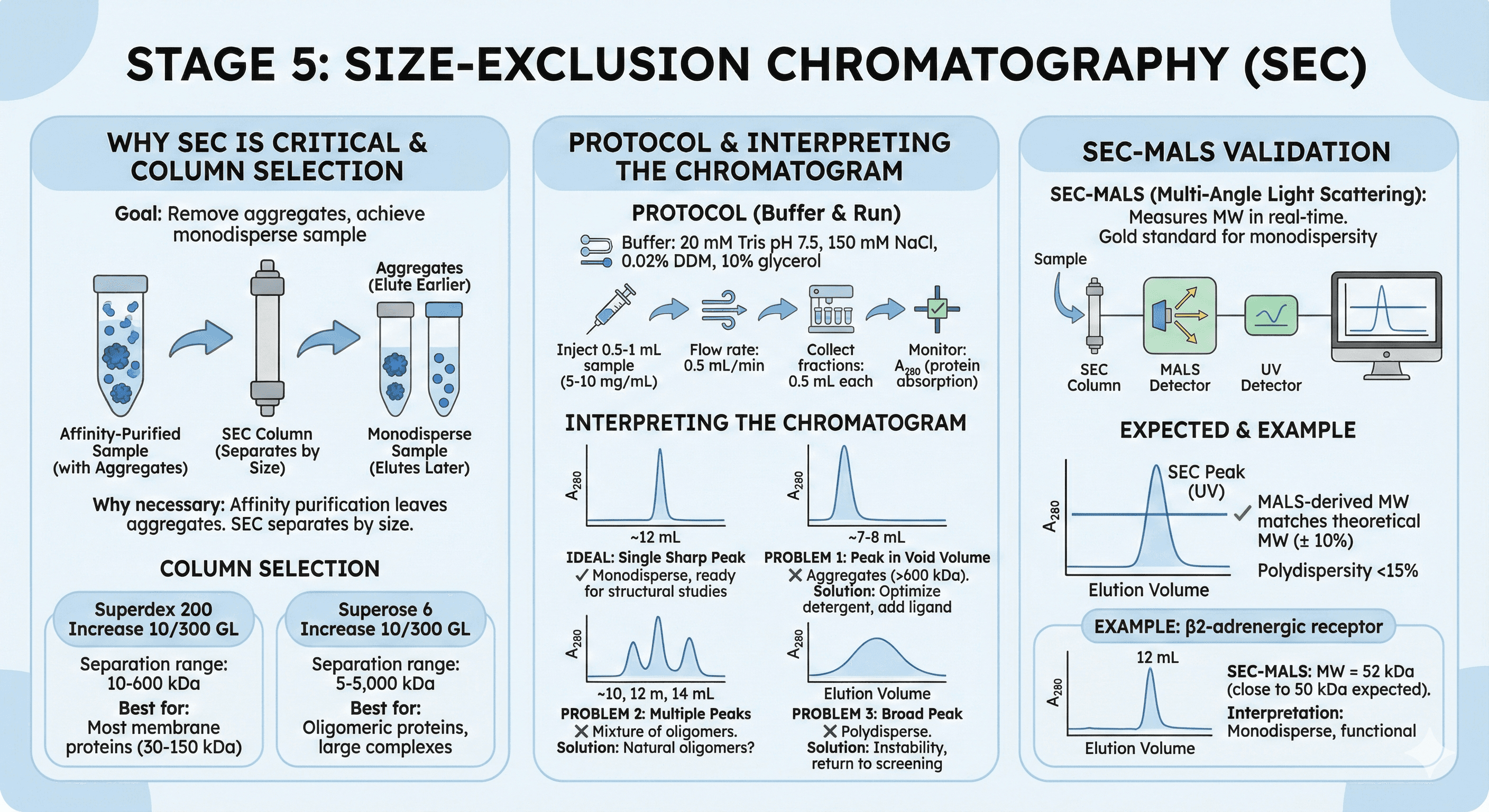

Stage 5: Size-Exclusion Chromatography (SEC)

Why SEC Is Critical

Goal: Remove aggregates, achieve monodisperse sample

Why necessary:

Affinity purification removes contaminants, but leaves aggregates

Aggregates interfere with structural studies (heterogeneous)

SEC separates by size: Monomers elute later, aggregates elute earlier

Column Selection

Superdex 200 Increase 10/300 GL:

Separation range: 10-600 kDa

Best for: Most membrane proteins (30-150 kDa)

Superose 6 Increase 10/300 GL:

Separation range: 5-5,000 kDa

Best for: Oligomeric proteins, large complexes

Protocol

Buffer:

20 mM Tris pH 7.5, 150 mM NaCl

0.02% DDM (or your detergent, 10× CMC)

10% glycerol

Run:

Inject 0.5-1 mL sample (5-10 mg/mL)

Flow rate: 0.5 mL/min

Collect fractions: 0.5 mL each

Monitor: A₂₈₀ (protein absorption)

Interpreting the Chromatogram

Ideal: Single sharp peak

Elution volume: 10-14 mL (for 30-50 kDa on Superdex 200)

Peak width: Narrow (Gaussian)

Interpretation: Monodisperse, ready for structural studies

Problem 1: Peak in void volume (7-8 mL)

Interpretation: Aggregates (>600 kDa)

Solution: Optimize detergent, add ligand, lower concentration

Problem 2: Multiple peaks

Interpretation: Mixture of oligomers (monomer, dimer, tetramer)

Solution: Some proteins are naturally oligomeric (e.g., ion channels)

Problem 3: Broad peak

Interpretation: Polydisperse (mixture of aggregation states)

Solution: Indicates instability, return to detergent screening

SEC-MALS (Validation)

SEC-MALS (Multi-Angle Light Scattering):

Measures molecular weight in real-time

Gold standard for confirming monodispersity

Expected:

SEC peak elutes at expected volume

MALS-derived MW matches theoretical MW (± 10%)

Polydispersity <15%

Example:

β2-adrenergic receptor (50 kDa with T4-lysozyme fusion)

SEC-MALS: MW = 52 kDa (close to expected)

Interpretation: Monodisperse, functional

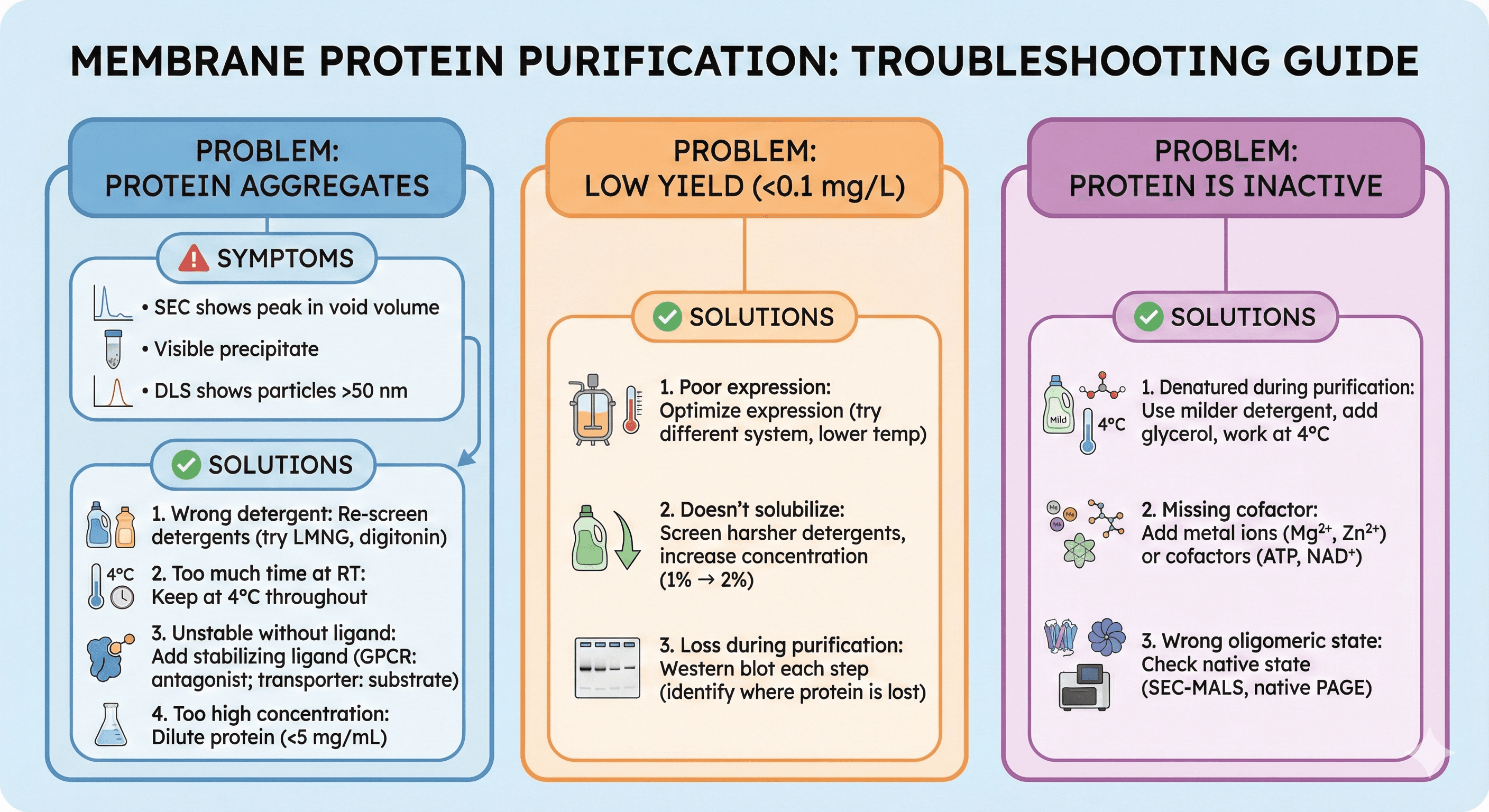

Troubleshooting Guide

Problem: Protein aggregates during purification

Symptoms:

SEC shows peak in void volume

Visible precipitate

DLS shows particles >50 nm

Solutions:

1. Wrong detergent

Re-screen detergents (try LMNG, digitonin)

2. Too much time at room temperature

Keep at 4°C throughout

3. Unstable without ligand

Add stabilizing ligand (GPCR: antagonist; transporter: substrate)

4. Too high concentration

Dilute protein (<5 mg/mL)

Problem: Low yield (<0.1 mg/L)

Solutions:

1. Poor expression

Optimize expression (try different system, lower temperature)

2. Doesn't solubilize

Screen harsher detergents, increase concentration (1% → 2%)

3. Loss during purification

Western blot each step (identify where protein is lost)

Problem: Protein is inactive

Solutions:

1. Denatured during purification

Use milder detergent, add glycerol, work at 4°C

2. Missing cofactor

Add metal ions (Mg²⁺, Zn²⁺) or cofactors (ATP, NAD⁺)

3. Wrong oligomeric state

Check native state (SEC-MALS, native PAGE)

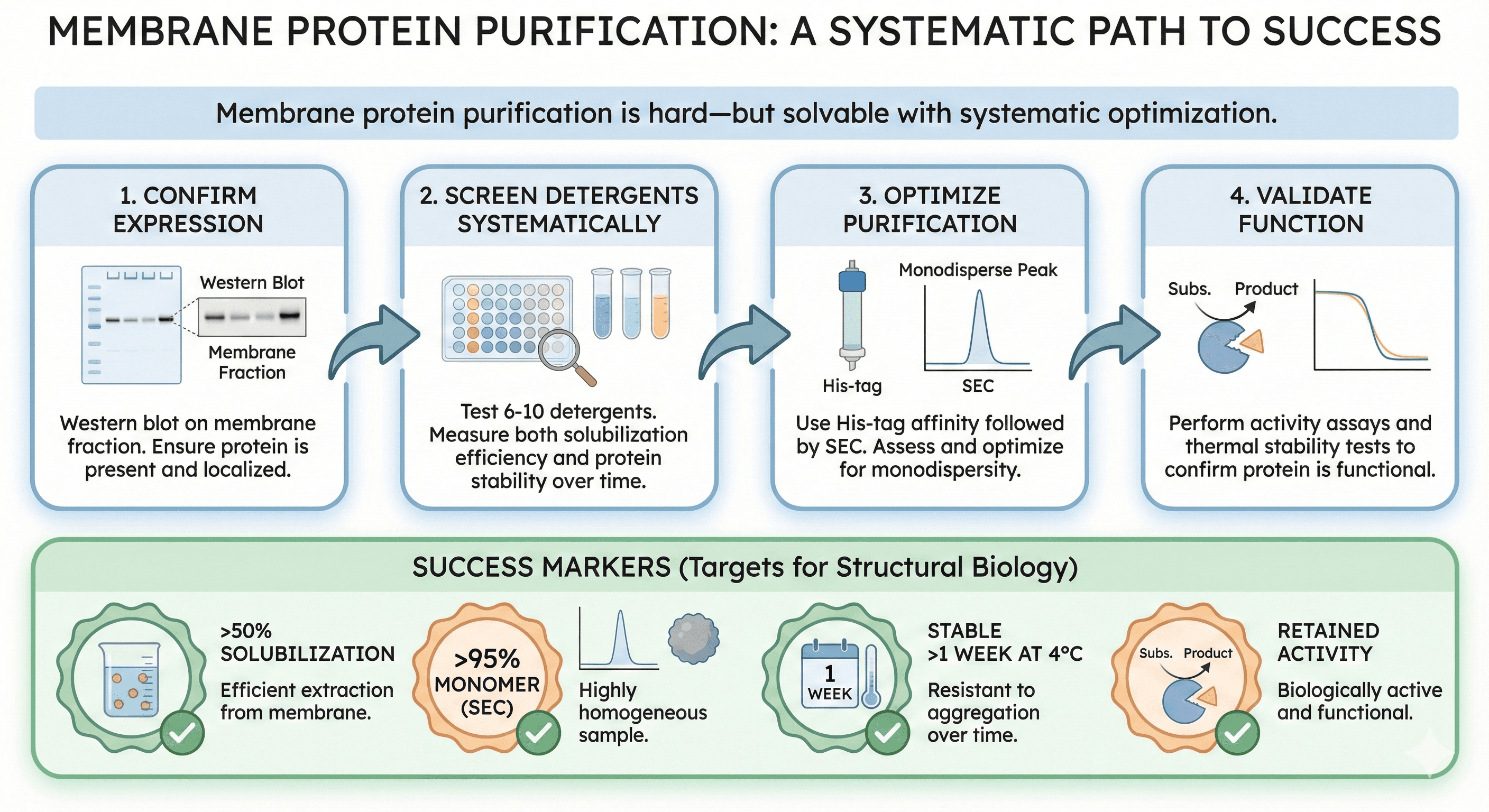

The Bottom Line

Membrane protein purification is hard—but solvable with systematic optimization.

The key steps:

Confirm expression (Western blot on membrane fraction)

Screen detergents systematically (test 6-10, measure solubilization + stability)

Optimize purification (His-tag, SEC, assess monodispersity)

Validate function (activity assay, thermal stability)

Success markers:

50% solubilization

95% monomer (SEC)

Stable >1 week at 4°C

Retained activity

Ready to Optimize Your Membrane Protein Purification?

If you're struggling with membrane protein stability or activity, Orbion can help design better constructs.

Orbion provides:

Thermostabilizing mutation predictions (increase Tm, reduce aggregation)

Construct boundary design (truncate disordered regions)

Membrane topology prediction (identify TM helices, loop regions)

Expression system recommendations

PTM prediction (glycosylation sites requiring mammalian expression)